| Revision as of 22:18, 5 March 2008 editBeagel (talk | contribs)Autopatrolled, Extended confirmed users, Pending changes reviewers, Rollbackers90,411 editsm fm numbers← Previous edit | Revision as of 11:43, 6 March 2008 edit undoHaus (talk | contribs)Autopatrolled, Extended confirmed users, Pending changes reviewers39,838 edits increase clarity in 1st use of DWTNext edit → | ||

| Line 19: | Line 19: | ||

| '''Oil tankers''', also known as '''petroleum tankers''', or '''tankers''' are ] designed for the bulk transport of ]. There are two basic types of oil tanker: the crude tanker and the product tanker.<ref name="hay2"/> Crude tankers move large quantities of unrefined ] from its point of extraction to refineries.<ref name="hay2"/> Product tankers, generally much smaller, are designed to move ] from refineries to points near consuming markets. | '''Oil tankers''', also known as '''petroleum tankers''', or '''tankers''' are ] designed for the bulk transport of ]. There are two basic types of oil tanker: the crude tanker and the product tanker.<ref name="hay2"/> Crude tankers move large quantities of unrefined ] from its point of extraction to refineries.<ref name="hay2"/> Product tankers, generally much smaller, are designed to move ] from refineries to points near consuming markets. | ||

| Oil tankers are often classified by their size as well as their occupation. The size classes range from inland or coastal tankers of a few thousand |

Oil tankers are often classified by their size as well as their occupation. The size classes range from inland or coastal tankers of a few thousand ]s of ] (DWT) to the mammoth '''supertankers''' of 650,000 DWT. | ||

| Tankers move approximately 2 billion tons of oil every year.<ref name="hub211">Huber, 2001: 211.</ref> Second only to pipelines in terms of efficiency,<ref name="hub211"/> the cost of tanker transport amounts to only two or three U.S. cents per gallon.<ref name="hub211"/> | Tankers move approximately 2 billion tons of oil every year.<ref name="hub211">Huber, 2001: 211.</ref> Second only to pipelines in terms of efficiency,<ref name="hub211"/> the cost of tanker transport amounts to only two or three U.S. cents per gallon.<ref name="hub211"/> | ||

Revision as of 11:43, 6 March 2008

Oil tankers, also known as petroleum tankers, or tankers are ships designed for the bulk transport of oil. There are two basic types of oil tanker: the crude tanker and the product tanker. Crude tankers move large quantities of unrefined crude oil from its point of extraction to refineries. Product tankers, generally much smaller, are designed to move petrochemicals from refineries to points near consuming markets.

Oil tankers are often classified by their size as well as their occupation. The size classes range from inland or coastal tankers of a few thousand long tons of deadweight (DWT) to the mammoth supertankers of 650,000 DWT.

Tankers move approximately 2 billion tons of oil every year. Second only to pipelines in terms of efficiency, the cost of tanker transport amounts to only two or three U.S. cents per gallon.

Some specialized types of oil tankers have evolved. One of these is the naval oiler, a tanker which can fuel a moving vessel. Combination Ore-bulk-oil carriers and permanently moored floating storage units are two other twists on the standard oil tanker design.

Oil tankers have been involved in a number of damaging and high-profile oil spills. As a result, they are subject to stringent design and operational regulations.

History

The technology of oil transportation has evolved alongside the oil industry. Although man's use of oil reaches to prehistory, the first modern commercial exploitation dates back to James Young's manufacture of parafin in 1850. In these early days, oil from Upper Burma was moved in earthenware vessels to the river bank where it was then poured into boat holds. In the 1850s, the Pennsylvania oil fields became a major supplier of oil, and a center of innovation. Break-bulk boats and barges were originally used to transport Pennsylvania oil in 40-gallon wooden barrels. The idea of moving bulk oil in specially-constructed tanks evolved quickly on America's railways, with modern-style cylindrical tank-cars emerging in 1871.

In 1863, two sail-driven tankers were built on the River Tyne. These were followed by the first oil-tank steamer, named the Vaderland. The first successful oil tanker was the Zoroaster, was designed by Ludvig Nobel (brother of Alfred Nobel) and built in 1877. This vessel had a displacement of 250 tons, with a length overall of 184 feet, a beam of 27 feet, and a draft of nine feet.

The Zoroaster plied the Caspian Sea from the Apsheron Peninsula, near Baku, in what was then the Russian Empire. Earlier designs suffered greatly from safety problems due to the free surface effect: as the tanker heaved in the sea, the oil would move more quickly than the water, causing ships to capsize. Nobel's tanker had proved itself in the unforgiving waters of the Atlantic ocean and his basic concept revolutionised the transport of oil.

In 1903, the Nobel brothers built two oil tankers which ran on internal combustion engines, as opposed to the older steam engines. The Vandale and Sarmat were each capable of carrying 750 tons of refined oil and powered by 360 horsepower diesel motors. This same firm soon went on to make much larger oil tankers, such as the Emanuel Nobel and Karl Hagelin, 4,600-ton kerosene tankers with 1,200 horsepower engines.

Size categories

| Oil Tanker Size Categories | |||

| Photo | Class | Tonnage (DWT) | Typical load (bbl) |

|---|---|---|---|

|

Seawaymax | 10,000-60,000 | |

| Panamax | 60,000-80,000 | ||

|

Aframax | 80,000-120,000 | 650,000 - 800,000 |

| Suezmax | 130,000-160,000 | 1,000,000 | |

|

VLCC | 200,000-320,000 | 2,000,000 |

| ULCC | over 320,000 | over 2,000,000 | |

| V Plus | over 440,000 | ||

Merchant oil tankers carry a wide range of hydrocarbon liquids ranging from crude oil to refined petroleum products. Their size is measured in deadweight tons (DWT). Crude carriers are among the largest, ranging from 55,000 DWT Panamax-sized vessels to Very Large Crude Carriers (VLCCs) of over 300,000 DWT.

At the smaller end of the spectrum lie product tankers, carrying refined cargoes range from well under 10,000 DWT to Panamax size. The smallest tankers, less than 10,000 DWT in capacity, work coastal and inland waterways. Examples of routes plied by small tankers include the Russian Volgotanker on the Volga River and lake tankers such as those used on Lake Maracaibo in Venezuela in 1923-53.

Supertanker is an informal term for the very largest tankers. Today it is applied to Very-Large Crude Carriers (VLCC) and Ultra-Large Crude Carriers (ULCC) above 250,000 DWT. These ships can transport two million barrels of oil. By way of comparison, the oil consumption of Spain and the UK combined is about 3.2 million barrels of oil a day. Ships of the smaller Aframax and Suezmax classes are no longer regarded as "supertankers".

The largest supertanker—indeed the world's largest ship ever —was the Jahre Viking or Seawise Giant (now the permanently moored storage tanker Knock Nevis), weighing in at 564,763 DWT. In the 1950s, tankers with only a tenth of that capacity would have been called supertankers.

The four largest supertankers, built circa 2002, carry the designation (V Plus), although the term ULCC has not been assigned a maximum DWT.

When first introduced, their size and draft prevented supertankers from docking at many existing docks, requiring them to discharge their cargo into smaller tankers offshore. Some ports have developed special deep-water off-loading facilities connected to the land by pipelines (such as the Louisiana Offshore Oil Port). Supertankers are also very efficient ships, mostly relying on a single propeller for propulsion, and therefore supertanker transport costs typically account for only US $0.02 per gallon of gas at the pump.

Current architecture

Oil tankers generally have from 8 to 12 tanks. Each tank is split into two or three independent compartments by fore-and-aft bulkheads. The tanks are numbered with tank one being the forwardmost. Individual compartments are referred to by the tank number and the athwartships position, such as "one port," "three starboard," or "six center."

A cofferdam is a small space left open between two bulkheads, to give protection from heat, fire, or collision. Tankers generally have cofferdams forward and aft of the cargo tanks, and sometimes between individual tanks.

A pumproom houses all the pumps connected to a tanker's cargo lines. Some larger tankers have two pumprooms. A pumproom generally spans the total breadth of the ship.

Hull designs

A major component of tanker architecture is the design of the hull or outer structure. A tanker with a single outer shell between the product and the ocean is said to be single-hulled. Most newer tankers are double-hulled, with an extra space between the hull and the storage tanks. Self-descriptive hybrid designs such as double-bottom and double-sided combine aspects of single and double-hull designs.

All single-hulled tankers around the world will be phased out by 2026, in accordance with the International Convention for the Prevention of Pollution from Ships, 1973.

In 1998, the Marine Board of the National Academy of Science conducted a survey of industry experts regarding the pros and cons of double-hull design. Some of the advantages of the double-hull design that were mentioned include:

- ease of ballasting in emergency situations,

- reduced practice of saltwater ballasting in cargo tanks decreases corrosion,

- increased environmental protection,

- cargo discharge is quicker, more complete and easier,

- tank washing is more efficient, and

- better protection in low-impact collisions and grounding.

The same report lists the following as some drawbacks to the double-hull design:

- more expensive to build,

- more expensive canal and port expenses,

- ballast tank ventilation difficult,

- ballast tanks need continual monitoring and maintenence,

- increased transverse free surface,

- more surfaces to maintain,

- explosion risk in double-hull spaces if vapor detection system not fitted,

- cleaning mud from ballast spaces a bigger problem.

In all, double-hull tankers are said to be safer than a single-hull in a grounding incident, especially when the shore is not very rocky.The safety benefits are less clear on larger vessels and in cases of high speed impact.

Inert gas system

An oil tanker's inert gas system is one of the most important parts of its design. Fuel oil is itself is very difficult to ignite, however its hydrocarbon vapors are explosive when mixed with air in certain concentrations. The purpose of the system is to create an atmosphere inside tanks in which the hydrocarbon oil vapors cannot burn.

As inert gas is introduced into a mixture of hydrocarbon vapors and air, it increases the lower flammable limit or lowest concentration at which the vapors can be ignited. At the same time it decreases the upper flammable limit or highest concentration at which the vapors can be ignited. When the total concentration of oxygen in the tank reaches about 11%, the upper and lower flammable limits converge and the flammable range disappears.

Inert gas systems deliver air with an oxygen concentration of less than 5% by volume. As a tank is pumped out, it's filled with inert gas and kept in this safe state until the next cargo is loaded. The exception is in cases when the tank must be entered. Safely gas-freeing a tank is accomplished by purging hydrocarbon vapors with inert gas until the hydrocarbon concentration inside the tank is under about 1%. Thus, as air replaces the inert gas, the concentration cannot rise to the lower flammable limit and is safe.

Cargo-related operations

Operations aboard oil tankers are governed by an established body of best practices and a large body of international law.

Pre-transfer preparation

Prior to any transfer of cargo, the Chief officer must develop a transfer plan detailing specifics of the operation such as how much cargo will be moved, which tanks will be cleaned, and how the ship's ballasting will change. The next step before a transfer is the pretransfer conference. The pretransfer conference covers issues such as:

- What products will be moved,

- In what order will products be moved,

- Names and titles of key people,

- Particulars of shipboard and shore equipment,

- Critical stages of the transfer,

- Federal, state, and local regulations in effect,

- Emergency and spill-containment procedures,

- Watch and shift arrangements, and

- Shutdown procedures

After the conference is complete, the person in charge on the ship and the person in charge of the shore installation go over a final inspection checklist. In the United States, the checklist is called a Declaration of Inspection or DOI. Outside of the U.S., the document is called the "Ship/Shore Safety Checklist." Items on the checklist include:

- Proper signals and signs are displayed,

- The vessel is securely moored,

- A language for all communication is chosen,

- All connections are secure,

- Emergency equipment is in place, and

- No repair work is taking place.

Loading cargo

Loading an oil tanker consists primarily of pumping cargo into the ship's tanks. As oil enters the tank, the vapors inside the tank must be somehow expelled. Depending on local regulations, the vapors can be expelled into the atmosphere or discharged back to the pumping station by way of a vapor recovery line. It is also common for the ship to move water balast during the loading of cargo to maintain proper trim.

Loading starts slowly at a low pressure to ensure that equipment is working correctly and that connections are secure. Then a steady pressure is achieved and held until the "topping-off" phase when the tanks are nearly full. Topping off is a very dangerous time in handling oil, and the procedure is handled particularly carefully. Tank-gauging equipment is used to tell the person in charge how much space is left in the tank, and all tankers have at least two independent methods for tank-gauging. As the tanker becomes full, crew members open and close valves to direct the flow of product and maintain close communication with the pumping facility to decrease and finally stop the flow of liquid.

Unloading cargo

The process of moving oil off of a tanker is similar to loading, but has some key differences. The first step in the operation is following the same pretransfer procedures as used in loading. When the transfer begins, it is the ship's cargo pumps that are used to move the product ashore. As in loading, the transfer starts at low pressure to ensure that equipment is working correctly and that connections are secure. Then a steady pressure is achieved and held during the operation. While pumping, tank levels are carefully watched and key locations, such as the connection at the cargo manifold and the ship's pumproom are constantly monitored. Under the direction of the person in charge, crew members open and close valves to direct the flow of product and maintain close communication with the receiving facility to decrease and finally stop the flow of liquid.

Tank cleaning

Tanks must be cleaned from time to time for various reasons. One reason is to change the type of product carried inside a tank. Also, when tanks are to be inspected or maintenance must be performed within a tank, it must be not only cleaned, but made "gas-free."

On most crude-oil tankers, a special crude oil washing (COW) system is part of the cleaning process. The COW system circulates part of the cargo through the fixed tank-cleaning system to remove wax and asphaltic deposits.

Tanks that carry less viscous cargoes are washed with water. Fixed and portable water washing systems exist. Some systems use rotating high-pressure water jets to spray hot water on all the internal surfaces of the tank. As the spraying takes place, the liquid is pumped out of the tank.

After a tank is cleaned, it may be gas-freed." This involves blowing fresh air into the tank to force accumulated gasses out. Specially trained personnel monitor the tank's atmosphere, often using hand-held gas indicators which measure the percentage of hydrocarbons present. When this percentage drops below a value specified in tank-vessel regulations, the tank is declared to be gas-free.

After a tank is gas-free, it may be further hand-cleaned in a process referred to as "mucking." This task is generally done by able seamen and deck officers using tools such as mops, buckets, rags and sponges.

Special-use oil tankers

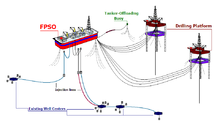

Some sub-types of oil tankers have evolved to meet specific military and economic needs. These sub-types include naval oilers, oil-bulk-ore combination carriers, Floating storage and offloading units (FSOs) and Floating production storage and offloading units (FPSOs).

Naval oilers

A naval oiler (called a fleet tanker in the Royal Fleet Auxiliary) is distinguished from other oil tankers by their ability to deliver fuel while making way in a process known as underway replenishment. Prior to the advent of this technique, naval vessels refuelled while in port or at anchor.

The fleet oiler USS Maumee, launched on April 17, 1915, pioneered the technique of underway replenishment. A large ship at the time, at 14,500 deadweight tons, Maumee began refuelling destroyers en route to Britain at the outset of World War I. This technique enabled the Navy to keep its fleets at sea for extended periods, with a far greater range independent of the availability of a friendly port. This independence proved crucial to victory in World War II by the ships commanded by Fleet Admiral Nimitz who, as Maumee’s executive officer, had played a key role in developing underway replenishment.

Underway replenishment was quickly adopted by other navies. One example of this is the Australian fleet oiler HMAS Kurumba which provided underway replenishment services in the United Kingdom's Royal Navy from 1917 to 1919.

Naval oilers may also carry water, ammunition, rations, stores and personnel.

Ore-bulk-oil carriers

An Ore-bulk-oil carrier, also known as combination carrier or OBO, is a ship designed to be capable of carrying wet or dry cargoes. The idea is to reduce the number of empty (ballast) voyages, in which large ships only carry a cargo one way and return empty for another. These are a feature of the larger bulk trades (e.g. crude oil from the Middle East, iron ore and coal from Australia, South Africa and Brazil).

Combination carriers found themselves specialising in one trade or the other, and their flexibility went very much unused. Very few were built after the 1980s, and the idea has rather fallen out of fashion. One of the more famous OBOs was the MV Derbyshire of 180,000 DWT, which in September 1980 became the largest British ship ever lost at sea. It sank in a Pacific typhoon while carrying a cargo of iron ore from Sept-Îles in Canada to Japan.

A fleet of smaller, "river-sized" ore-bulk-oil carriers of a few thousand DWT have been used for some decades on European Russia's waterways, primarily by Volgotanker. The Russian word for 'ore-bulk-oil carrier', nefterudovoz (нефтерудовоз, literally 'oil/ore carrier'), in combination with a number, is often used as a proper name for a ship, e.g. Nefterudovoz-51M'.

Floating storage units

A Floating production storage and offloading unit is a type of floating tank system used by the offshore oil and gas industry. These units are designed to take all of the oil or gas produced by one or more nearby platforms, process it, and store it until the oil or gas can be offloaded onto waiting oil tankers. A Floating storage and offloading unit is a similar system, but without the possibility to do any processing of the oil or gas.

These units are often created out of old, stripped-down oil tankers. An example of a FSO that used to be an oil tanker is the Knock Nevis.

Pollution

Oil spills have devastating effects on the environment. Crude oil contains polycyclic aromatic hydrocarbons (PAHs) which is very difficult to clean up, and lasts for years in the sediment and marine environment. Marine species constantly exposed to PAHs can exhibit developmental problems, susceptibility to disease, and abnormal reproductive cycles.

By the sheer amount of oil carried, modern oil tankers must be considered something of a threat to the environment. As discussed above, a VLCC tanker can carry 2 million barrels of crude oil, or 62,000,000 gallons. This is more than six times the amount spilled in the widely known Exxon Valdez incident. In this spill, the ship ran aground and dumped 10.8 million gallons of oil into the ocean in March of 1989. Despite efforts of scientists, managers, and volunteers over 400,000 seabirds, about 1,000 sea otters, and immense numbers of fish were killed.

But how much do tankers contribute to oil pollution in the oceans? According to the United States Coast Guard, 35.7 % of the volume of oil spilled in the U.S. from 1991 to 2004 came from tank vessels (ships/barges), 27.6 % from facilities and other non-vessels, 19.9% from non-tank vessels, and 9.3 % from pipelines; 7.4 % from mystery spills. On the other hand, only 5% of the actual spills came from oil tankers, while 51.8% came from other kinds of vessels. The detailed statistics for 2004 shown in the table below show tank vessels responsible for somewhat less than 5 % of the number of total spills but more than 60% of the volume. In summary, spills are much more rare but much more serious on tank vessels than on non-tank vessels.

| U.S.C.G Spill Compendium Annual Data for 2004 | |||||||

| Source | Number of spills | % of spill incidents | Spill volume (gallons) | % of spill volume | Average spill size | Median spill size | Maximum spill size |

|---|---|---|---|---|---|---|---|

| TANKSHIP | 35 | 0.90% | 636,834 | 45.00% | 18,195 | 1 | 329,678 |

| TANKBARGE | 143 | 3.70% | 215,822 | 15.20% | 1,509 | 3 | 151,200 |

| ALL OTHER VESSELS | 1527 | 39.20% | 453,901 | 32.00% | 297 | 3 | 335,732 |

| FACILITIES | 1099 | 28.20% | 42,675 | 3.00% | 39 | 1 | 2,100 |

| PIPELINES | 1 | 0.00% | 15,000 | 1.10% | 15,000 | 15,000 | 15,000 |

| ALL OTHER NON-VESSEL SOURCES | 37 | 0.90% | 12,781 | 0.90% | 345 | 5 | 12,000 |

| UNKNOWN or OTHER | 1055 | 27.10% | 39,700 | 2.80% | 38 | 1 | 8,000 |

| YEAR-END STATISTICS | 3897 | 100.00% | 1,416,714 | 100.00% | 364 | 2 | 335,732 |

The International Tanker Owners Pollution Federation has tracked 9,351 accidental spills that have occurred since 1974. According to this study, most spills result from routine operations such as loading cargo, discharging cargo, and taking on fuel oil. 91% of the operational oil spills are small, resulting in less than 7 tons per spill. On the other hand, spills resulting from accidents like collisions, groundings, hull failures, and explosions are much larger, with 84% of these involving losses of over 700 tons.

Following the Exxon Valdez spill, the United States passed the Oil Pollution Act of 1990 (OPA-90), which included a stipulation that all tankers entering its waters be double-hulled by 2015. Following the sinkings of the Erika (1999) and Prestige (2002), the European Union passed its own stringent anti-pollution packages (known as Erika I, II, and III), which also require all tankers entering its waters to be double-hulled by 2010. The Erika packages are controversial because they introduced the new legal concept of "serious negligence".

Today's fleet

Flag states

As of 2007, the United States Central Intelligence Agency statistics count 4,295 oil tankers of 1,000 deadweight tons or greater worldwide. Panama was the world's largest flag state for oil tankers, with 528 of the vessels in its registry. Six other flag states had more than 200 registered oil tankers: Liberia (464), Singapore (355), China (252), Russia (250), the Marshall Islands (234) and The Bahamas (209). By way of comparison, the United States and the United Kingdom only had 59 and 27 registered oil tankers, respectively.

See also

- Category:Tankers

- Marine transfer operations

- MARPOL 73/78

- Stavros Niarchos

- Aristotle Onassis

- Prestige oil spill

- Replenishment oiler

- T2 tanker

- Daniel K. Ludwig

- Tanker (ship)

- List of oil spills

- List of tankers

- List of replenishment ships of the Royal Fleet Auxiliary

- List of Type T2 Tanker names

Notes

- ^ Hayler and Keever, 2003:14-2.

- ^ Huber, 2001: 211.

- Delgado, James (1988). "Falls of Clyde National Historic Landmark Study". Maritime Heritage Program. National Park Service. Retrieved 2008-02-24.

- Chisholm, 19:316.

- ^ Chisholm, 19:320.

- ^ Chisholm, 24:881.

- Chisholm, 24:881-882.

- Chisholm, 24:882.

- Note: definitions of what size of tanker constitute what type e.g. whether a 320,000 DWT tanker is VLCC or a ULCC, varies from broker to broker, lawyer to lawyer and ship owner to ship owner. As there is no set, standard, classification, there is no one 'correct' answer. All descriptions of X-size being an X-tanker should be treated with caution.

- USCG PSIX

- ^ Hayler and Keever, 2003:14-3.

- Energy Statistics > Oil > Consumption by country

- These four sister ships were built by Hellespont Steamship Corporation at the Daewoo shipyard. They are currently named TI Asia, TI Europe, TI Oceania, and TI Africa.

- Education Section: Basic Glossary. Tankers International.

- The History Channel. Modern Marvels: Supertankers.

- ^ Turpin and McEven, 1980:8-24. Cite error: The named reference "tur824" was defined multiple times with different content (see the help page).

- Turpin and McEven, 1980:8-25.

- ^ Hayler and Keever, 2003:14-4.

- "Double-Hull Tanker Legislation: An Assessment of the Oil Pollution Act of 1990 (1998)". Marine Board Commission on Engineering and Technical Systems. Retrieved 2007-04-10.

- ^ "Double-Hull Tanker Legislation: An Assessment of the Oil Pollution Act of 1990 (1998)". Marine Board Commission on Engineering and Technical Systems. Retrieved 2007-04-10.

- ^ "Double-Hull Tanker Legislation: An Assessment of the Oil Pollution Act of 1990 (1998)". Marine Board Commission on Engineering and Technical Systems. Retrieved 2007-04-10.

- ^ "Double-Hull Tanker Legislation: An Assessment of the Oil Pollution Act of 1990 (1998)". Marine Board Commission on Engineering and Technical Systems. Retrieved 2007-04-10.

- Joem K. Paik and Tak K. Lee, Damage and Residual Strength of Double-Hull Tankers in Grounding, International Journal of Offshore and Polar Engineering, Vol. 5, No. 4, December 1995.

- [http://www.earthtoys.com/emagazine.php?issue_number=07.02.01&article=green_ships Earthtoys - Emagazine

- Double, double, oil and trouble in Fairplay International Shipping Weekly, 23 Jun 2005.

- ^ Hayler and Keever, 2003:14-11.

- Turpin and McEwin, 1980:16-42.

- ^ Transport Canada, 1985:4.

- Transport Canada, 1985:5.

- ^ Transport Canada, 1985:9.

- Hayler and Keever, 2003:14-1.

- Hayler and Keever, 2003:14-6.

- ^ Hayler and Keever, 2003:14-7.

- ^ Hayler and Keever, 2003:14-8.

- ^ Turpin and McEven, 1980:8-30.

- ^ Hayler and Keever, 2003:14-9.

- Hayler and Keever, 2003:14-10.

- ^ Hayler and Keever, 2003:14-12.

- ^ Hayler and Keever, 2003:14-13.

- ^ Navy Dept., Office of the Chief of Naval Operations, Naval History Division. Dictionary of American Naval Fighting Ships Volume 6. ISBN 0160020301. Retrieved 23.

{{cite book}}: Check|authorlink=value (help); Check date values in:|accessdate=(help); Cite has empty unknown parameters:|month=,|chapterurl=, and|coauthors=(help); Unknown parameter|accessmonth=ignored (|access-date=suggested) (help); Unknown parameter|accessyear=ignored (|access-date=suggested) (help); Unknown parameter|origdate=ignored (|orig-date=suggested) (help); Unknown parameter|origmonth=ignored (help)CS1 maint: multiple names: authors list (link) - ^ "Navy Contribution to Australian Maritime Operations". Royal Australian Navy. Retrieved 2008-02-23.

- Ship listing of the type "Nefterudovoz"

- [http://www.shipphotos.co.uk/pages/nefterudovoz51m.htm Ship photos - Nefterudovoz-51M

- "Frequently asked questions about the Exxon Valdez Oil Spill". State of Alaska.

- ^ Panetta, L. E. (Chair) (2003). America's living oceans: charting a course for sea change Pew Oceans Commission.

- ^ Cumulative Spill Data and Graphics

- [http://www.uscg.mil/hq/g-m/nmc/response/stats/Data2004.htm#OILG Oil Spills In U.S. Waters Calendar Year 2004]

- ^ International Tanker Owners Pollution Federation Statistics

- European Parliament. Directive 2005/35/EC of the European Parliament and of the Council of 7 September 2005 on ship-source pollution and on the introduction of penalties for infringements. Retrieved 02-22-2008.

{{cite book}}: Check date values in:|accessdate=(help); Cite has empty unknown parameters:|accessyear=,|origmonth=,|accessmonth=,|month=,|chapterurl=, and|coauthors=(help); Unknown parameter|origdate=ignored (|orig-date=suggested) (help) - ^ Central Intelligence Agency, 2007.

References

- Double double, toil and trouble. Fairplay International Shipping Magazine. 23 Jun 2005.

{{cite book}}: CS1 maint: year (link) - Central Intelligence Agency (2007). CIA World Factbook 2008. Skyhorse Publishing. ISBN 1602390800. Retrieved 2008-02-22.

{{cite book}}: Cite has empty unknown parameters:|accessyear=,|origmonth=,|accessmonth=,|month=,|chapterurl=,|origdate=, and|coauthors=(help) - Jack Devanney (2006). The Tankship Tromedy: The Impending Disasters in Tankers. The CTX Press. ISBN 0-9776479-0-0.

- Encyclopædia Britannica (1911). "Petroleum". In Chisholm, Hugh (ed.). Encyclopædia Britannica. Vol. 21 (11th edition ed.). pp. 316–322. Retrieved 2008-02-22.

{{cite encyclopedia}}:|edition=has extra text (help); Cite has empty unknown parameters:|accessmonth=,|month=,|accessyear=, and|coauthors=(help) - Encyclopædia Britannica (1911). "Ship". In Chisholm, Hugh (ed.). Encyclopædia Britannica. Vol. 24 (11th edition ed.). pp. 881–889. Retrieved 2008-02-22.

{{cite encyclopedia}}:|edition=has extra text (help); Cite has empty unknown parameters:|accessmonth=,|month=,|accessyear=, and|coauthors=(help) - European Commission / European Maritime Safety Agency (2005). Double Hull Tankers: High Level Panel of Experts Report.

- Hayler, William B. (2003). American Merchant Seaman's Manual. Cornell Maritime Pr. ISBN 0-87033-549-9.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - Huber, Mark (2001). Tanker operations: a handbook for the person-in-charge (PIC). Cambridge, MD: Cornell Maritime Press. ISBN 0-87033-528-6.

- International Chamber of Shipping (1996). International Safety Guide for Oil Tankers and Terminals (ISGOTT). New York: Hyperion Books. ISBN 1-85609-081-7.

- Office of Data and Economic Analysis (2006). "World Merchant Fleet 2001–2005" (PDF). United States Maritime Administration. Retrieved March 13.

{{cite web}}: Check date values in:|accessdate=(help); Cite has empty unknown parameter:|coauthors=(help); Unknown parameter|accessyear=ignored (|access-date=suggested) (help); Unknown parameter|month=ignored (help) - Sawyer, L. A.; Mitchell, W. O. (1987). Sailing ship to supertanker: the hundred-year story of British Esso and its ships. Lavenham, Suffolk: Terence Dalton. ISBN 0-86138-055-X.

{{cite book}}: CS1 maint: multiple names: authors list (link) - Transport Canada (1984). Standard for Inert Gas Systems (PDF).

{{cite book}}: Cite has empty unknown parameters:|accessyear=,|origmonth=,|accessmonth=,|month=,|chapterurl=,|origdate=, and|coauthors=(help) - Turpin, Edward A. (1980). Merchant Marine Officers' Handbook (4th ed.). Centreville, MD: Cornell Maritime Press. ISBN 0-87038-056-X.

{{cite book}}: Check|isbn=value: checksum (help); Cite has empty unknown parameters:|accessyear=,|origmonth=,|accessmonth=,|month=,|chapterurl=, and|origdate=(help); Unknown parameter|coauthors=ignored (|author=suggested) (help)

Further reading

- Spyrou, Andrew G. From T-2 to Supertanker: Development of the Oil Tanker, 1940-2000. : iUniverse, Inc. ISBN 0-595-36068-8.

- Sullivan, George. Supertanker!: The Story of the World's Biggest Ships. New York: Dodd Mead. ISBN 0-396-07527-4.

External links

- Bill Willis. Supertankers

- Intertanko - the society of International Tanker Operators

- The International Maritime Organization - Tanker Safety (for double-hulls)

| Modern merchant ships | ||

|---|---|---|

| Overviews | ||

| Dry cargo | ||

| Tankers | ||

| Passenger | ||

| Support | ||

| Other types | ||

| Related | ||