| Revision as of 05:55, 29 November 2012 edit150.203.35.193 (talk) →Occurrence: It is rutile that is metastable!← Previous edit | Revision as of 06:06, 29 November 2012 edit undoMaterialscientist (talk | contribs)Edit filter managers, Autopatrolled, Checkusers, Administrators1,994,292 edits rvt: here theory fails to explain the experiment, see e.g. dicussion in http://iopscience.iop.org/0953-8984/24/42/424206/articleNext edit → | ||

| Line 73: | Line 73: | ||

| ==Occurrence== | ==Occurrence== | ||

| Titanium dioxide occurs in nature as well-known minerals ], ] and ], and additionally as two high pressure forms, a ] ]-like form and an ] ]-like form, both found recently at the ] in ].<ref>{{cite journal|doi=10.1126/science.1062342|year=2001|title=An ultradense polymorph of rutile with seven-coordinated titanium from the Ries crater.|volume=293|issue=5534|pages=1467–70|pmid=11520981|journal=Science|author1=El, Goresy|author2=Chen, M|author3=Dubrovinsky, L|author4=Gillet, P|author5=Graup, G}}</ref><ref>{{cite journal|doi=10.1016/S0012-821X(01)00480-0|title=A natural shock-induced dense polymorph of rutile with α-PbO2 structure in the suevite from the Ries crater in Germany|year=2001|author=El Goresy, Ahmed|journal=Earth and Planetary Science Letters|volume=192|pages=485|last2=Chen|first2=Ming|last3=Gillet|first3=Philippe|last4=Dubrovinsky|first4=Leonid|last5=Graup|first5=GüNther|last6=Ahuja|first6=Rajeev|bibcode=2001E&PSL.192..485E|issue=4}}</ref> It is mainly sourced from ] ore. This is the most wide spread form of titanium dioxide-bearing ore around the world. Rutile is the next most abundant and contains around 98% titanium dioxide in the ore. |

Titanium dioxide occurs in nature as well-known minerals ], ] and ], and additionally as two high pressure forms, a ] ]-like form and an ] ]-like form, both found recently at the ] in ].<ref>{{cite journal|doi=10.1126/science.1062342|year=2001|title=An ultradense polymorph of rutile with seven-coordinated titanium from the Ries crater.|volume=293|issue=5534|pages=1467–70|pmid=11520981|journal=Science|author1=El, Goresy|author2=Chen, M|author3=Dubrovinsky, L|author4=Gillet, P|author5=Graup, G}}</ref><ref>{{cite journal|doi=10.1016/S0012-821X(01)00480-0|title=A natural shock-induced dense polymorph of rutile with α-PbO2 structure in the suevite from the Ries crater in Germany|year=2001|author=El Goresy, Ahmed|journal=Earth and Planetary Science Letters|volume=192|pages=485|last2=Chen|first2=Ming|last3=Gillet|first3=Philippe|last4=Dubrovinsky|first4=Leonid|last5=Graup|first5=GüNther|last6=Ahuja|first6=Rajeev|bibcode=2001E&PSL.192..485E|issue=4}}</ref> It is mainly sourced from ] ore. This is the most wide spread form of titanium dioxide-bearing ore around the world. Rutile is the next most abundant and contains around 98% titanium dioxide in the ore.The metastable ] and ] phases convert to rutile upon heating.<ref name = "Greenwood">{{Greenwood&Earnshaw1st|pages=1117–19}}</ref> | ||

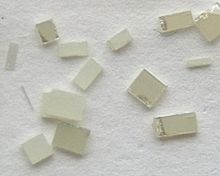

| Titanium dioxide has eight modifications – in addition to rutile, anatase, and brookite three metastable phases can be produced synthetically (], ] and orthorombic), and five high pressure forms (α-PbO<sub>2</sub>-like, ]-like, ]-like, orthorhombic OI, and cubic phases): | Titanium dioxide has eight modifications – in addition to rutile, anatase, and brookite three metastable phases can be produced synthetically (], ] and orthorombic), and five high pressure forms (α-PbO<sub>2</sub>-like, ]-like, ]-like, orthorhombic OI, and cubic phases): | ||

Revision as of 06:06, 29 November 2012

| |

| |

| Names | |

|---|---|

| IUPAC names

Titanium dioxide Titanium(IV) oxide | |

| Other names

Titania Rutile Anatase Brookite | |

| Identifiers | |

| CAS Number | |

| 3D model (JSmol) | |

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.033.327 |

| E number | E171 (colours) |

| KEGG | |

| PubChem CID | |

| RTECS number |

|

| UNII | |

| CompTox Dashboard (EPA) | |

InChI

| |

SMILES

| |

| Properties | |

| Chemical formula | TiO 2 |

| Molar mass | 79.866 g/mol |

| Appearance | White solid |

| Odor | odorless |

| Density | 4.23 g/cm |

| Melting point | 1843 °C |

| Boiling point | 2972 °C |

| Solubility in water | insoluble |

| Refractive index (nD) | 2.488 (anatase) 2.583 (brookite) 2.609 (rutile) |

| Thermochemistry | |

| Std molar entropy (S298) |

50 J·mol·K |

| Std enthalpy of formation (ΔfH298) |

−945 kJ·mol |

| Hazards | |

| NFPA 704 (fire diamond) |

|

| Flash point | Non-flammable |

| Related compounds | |

| Other cations | Zirconium dioxide Hafnium dioxide |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C , 100 kPa).

| |

Titanium dioxide, also known as titanium(IV) oxide or titania, is the naturally occurring oxide of titanium, chemical formula TiO

2. When used as a pigment, it is called titanium white, Pigment White 6, or CI 77891. Generally it is sourced from ilminite, rutile and anatase. It has a wide range of applications, from paint to sunscreen to food colouring. When used as a food colouring, it has E number E171.

Occurrence

Titanium dioxide occurs in nature as well-known minerals rutile, anatase and brookite, and additionally as two high pressure forms, a monoclinic baddeleyite-like form and an orthorhombic α-PbO2-like form, both found recently at the Ries crater in Bavaria. It is mainly sourced from ilmenite ore. This is the most wide spread form of titanium dioxide-bearing ore around the world. Rutile is the next most abundant and contains around 98% titanium dioxide in the ore.The metastable anatase and brookite phases convert to rutile upon heating.

Titanium dioxide has eight modifications – in addition to rutile, anatase, and brookite three metastable phases can be produced synthetically (monoclinic, tetragonal and orthorombic), and five high pressure forms (α-PbO2-like, baddeleyite-like, cotunnite-like, orthorhombic OI, and cubic phases):

| Form | Crystal system | Synthesis |

|---|---|---|

| rutile | tetragonal | |

| anatase | tetragonal | |

| brookite | orthorhombic | |

| TiO2(B) | monoclinic | Hydrolysis of K2Ti4O9 followed by heating |

| TiO2(H), hollandite-like form | tetragonal | Oxidation of the related potassium titanate bronze, K0.25TiO2 |

| TiO2(R), ramsdellite-like form | orthorhombic | Oxidation of the related lithium titanate bronze Li0.5TiO2 |

| TiO2(II)-(α-PbO2-like form) | orthorhombic | |

| baddeleyite-like form, (7 coordinated Ti) | monoclinic | |

| TiO2 -OI | orthorhombic | |

| cubic form | cubic | P > 40 GPa, T > 1600 °C |

| TiO2 -OII, cotunnite(PbCl2)-like | orthorhombic | P > 40 GPa, T > 700 °C |

The cotunnite-type phase was claimed by L. Dubrovinsky and co-authors to be the hardest known oxide with the Vickers hardness of 38 GPa and the bulk modulus of 431 GPa (i.e. close to diamond's value of 446 GPa) at atmospheric pressure. However, later studies came to different conclusions with much lower values for both the hardness (7–20 GPa, which makes it softer than common oxides like corundum Al2O3 and rutile TiO2) and bulk modulus (~300 GPa).

The oxides are commercially important ores of titanium. The metal can also be mined from other minerals such as ilmenite or leucoxene ores, or one of the purest forms, rutile beach sand. Star sapphires and rubies get their asterism from rutile impurities present in them.

Titanium dioxide (B) is found as a mineral in magmatic rocks and hydrothermal veins, as well as weathering rims on perovskite. TiO2 also forms lamellae in other minerals.

Spectral lines from titanium oxide are prominent in class M stars, which are cool enough to allow molecules of this chemical to form.

Production

The production method depends on the feedstock. The most common method for the production of titanium dioxide utilizes ilmenite. Ilmenite is mixed with sulfuric acid. This reacts to remove the iron oxide group in the ilmenite. The by-product iron(II) sulfate is crystallized and filtered-off to yield only the titanium salt in the digestion solution. This product is called synthetic rutile. This is further processed in a similar way to rutile to give the titanium dioxide product. Synthetic rutile and titanium slags are made especially for titanium dioxide production. The use of ilminite ore usually only produces pigment grade titanium dioxide. Another method for the production of synthetic rutile from ilminite utilizes the Becher Process.

Rutile is the second most abundant mineral sand. Rutile found in primary rock cannot be extracted hence the deposits containing rutile sand can be mined meaning a reduced availability to the high concentration ore. Crude titanium dioxide (in the form of rutile or sunthetic rutile) is purified via converting to titanium tetrachloride in the chloride process. In this process, the crude ore (containing at least 70% TiO2) is reduced with carbon, oxidized with chlorine to give titanium tetrachloride; i.e., carbothermal chlorination. This titanium tetrachloride is distilled, and re-oxidized in a pure oxygen flame or plasma at 1500–2000 K to give pure titanium dioxide while also regenerating chlorine. Aluminium chloride is often added to the process as a rutile promotor; the product is mostly anatase in its absence. The preferred raw material for the chloride process is natural rutile because of its high titanium dioxide content.

One method for the production of titanium dioxide with relevance to nanotechnology is solvothermal Synthesis of titanium dioxide.

Nanotubes

Anatase can be converted by hydrothermal synthesis to delaminated anatase inorganic nanotubes and titanate nanoribbons which are of potential interest as catalytic supports and photocatalysts. In the synthesis, anatase is mixed with 10 M sodium hydroxide and heated at 130 °C for 72 hours. The reaction product is washed with dilute hydrochloric acid and heated at 400 °C for another 15 hours. The yield of nanotubes is quantitative and the tubes have an outer diameter of 10 to 20 nm and an inner diameter of 5 to 8 nm and have a length of 1 μm. A higher reaction temperature (170 °C) and less reaction volume gives the corresponding nanowires.

Another process for synthesizing TiO

2 is through anodization in an electrolytic solution. When anodized in a 0.5 weight percent HF solution for 20 minutes, well-aligned titanium oxide nanotube arrays can be fabricated an average tube diameter of 60 nm and length of 250 nm. Based on X-ray Diffraction, nanotubes grown through anodization are amorphous.

Applications

Pigment

Titanium dioxide is the most widely used white pigment because of its brightness and very high refractive index, in which it is surpassed only by a few other materials. Approximately 4.6 million tons of pigmentary TiO2 are consumed annually worldwide, and this number is expected to increase as consumption continues to rise. When deposited as a thin film, its refractive index and colour make it an excellent reflective optical coating for dielectric mirrors and some gemstones like "mystic fire topaz". TiO2 is also an effective opacifier in powder form, where it is employed as a pigment to provide whiteness and opacity to products such as paints, coatings, plastics, papers, inks, foods, medicines (i.e. pills and tablets) as well as most toothpastes. In paint, it is often referred to offhandedly as "the perfect white", "the whitest white", or other similar terms. Opacity is improved by optimal sizing of the titanium dioxide particles.

In ceramic glazes titanium dioxide acts as an opacifier and seeds crystal formation.

Titanium dioxide has been shown statistically to increase skimmed milk's whiteness, increasing skimmed milk's sensory acceptance score.

Titanium dioxide is used to mark the white lines of some tennis courts.

The exterior of the Saturn V rocket was painted with titanium dioxide; this later allowed astronomers to determine that J002E3 was the S-IVB stage from Apollo 12 and not an asteroid.

Sunscreen and UV absorber

In cosmetic and skin care products, titanium dioxide is used as a pigment, sunscreen and a thickener. It is also used as a tattoo pigment and in styptic pencils. Titanium dioxide is produced in varying particle sizes, oil and water dispersible, and with varying coatings for the cosmetic industry. This pigment is used extensively in plastics and other applications for its UV resistant properties where it acts as a UV absorber, efficiently transforming destructive UV light energy into heat.

Titanium dioxide is found in almost every sunscreen with a physical blocker because of its high refractive index, its strong UV light absorbing capabilities and its resistance to discolouration under ultraviolet light. This advantage enhances its stability and ability to protect the skin from ultraviolet light. Nano-scaled titanium dioxide particles are primarily used in sun screen lotion because they scatter visible light less than titanium dioxide pigments while still providing UV protection. Sunscreens designed for infants or people with sensitive skin are often based on titanium dioxide and/or zinc oxide, as these mineral UV blockers are believed to cause less skin irritation than other UV absorbing chemicals. The titanium dioxide particles used in sunscreens have to be coated with silica or alumina, because titanium dioxide creates radicals in the photocatalytic reaction. These radicals are carcinogenic, and could damage the skin.

Photocatalyst

Titanium dioxide, particularly in the anatase form, is a photocatalyst under ultraviolet (UV) light. Recently it has been found that titanium dioxide, when spiked with nitrogen ions or doped with metal oxide like tungsten trioxide, is also a photocatalyst under either visible or UV light. The strong oxidative potential of the positive holes oxidizes water to create hydroxyl radicals. It can also oxidize oxygen or organic materials directly. Titanium dioxide is thus added to paints, cements, windows, tiles, or other products for its sterilizing, deodorizing and anti-fouling properties and is used as a hydrolysis catalyst. It is also used in dye-sensitized solar cells, which are a type of chemical solar cell (also known as a Graetzel cell).

The photocatalytic properties of titanium dioxide were discovered by Akira Fujishima in 1967 and published in 1972. The process on the surface of the titanium dioxide was called the Honda-Fujishima effect. Titanium dioxide has potential for use in energy production: as a photocatalyst, it can carry out hydrolysis; i.e., break water into hydrogen and oxygen. Were the hydrogen collected, it could be used as a fuel. The efficiency of this process can be greatly improved by doping the oxide with carbon. Further efficiency and durability has been obtained by introducing disorder to the lattice structure of the surface layer of titanium dioxide nanocrystals, permitting infrared absorption.

Titanium dioxide can also produce electricity when in nanoparticle form. Research suggests that by using these nanoparticles to form the pixels of a screen, they generate electricity when transparent and under the influence of light. If subjected to electricity on the other hand, the nanoparticles blacken, forming the basic characteristics of a LCD screen. According to creator Zoran Radivojevic, Nokia has already built a functional 200-by-200-pixel monochromatic screen which is energetically self-sufficient.

In 1995 Fujishima and his group discovered the superhydrophilicity phenomenon for titanium dioxide coated glass exposed to sun light. This resulted in the development of self-cleaning glass and anti-fogging coatings.

TiO2 incorporated into outdoor building materials, such as paving stones in noxer blocks or paints, can substantially reduce concentrations of airborne pollutants such as volatile organic compounds and nitrogen oxides.

A photocatalytic cement that uses titanium dioxide as a primary component, produced by Italcementi Group, was included in Time's Top 50 Inventions of 2008.

Attempts have been made to photocatalytically mineralize pollutants (to convert into CO2 and H2O) in waste water. TiO2 offers great potential as an industrial technology for detoxification or remediation of wastewater due to several factors:

- The process uses natural oxygen and sunlight and thus occurs under ambient conditions; it is wavelength selective and is accelerated by UV light.

- The photocatalyst is inexpensive, readily available, non-toxic, chemically and mechanically stable, and has a high turnover.

- The formation of photocyclized intermediate products, unlike direct photolysis techniques, is avoided.

- Oxidation of the substrates to CO2 is complete.

- TiO2 can be supported on suitable reactor substrates.

Electronic data storage medium

In 2010, researchers at the University of Tokyo, Japan have created a crystal form of titanium oxide with particles 5 to 20 nanometers that can be switched between two states with light. Use of the 5 nm particles could theoretically lead to a 25 TB storage disc.

Other applications

- Titanium dioxide in solution or suspension can be used to cleave protein that contains the amino acid proline at the site where proline is present. This breakthrough in cost-effective protein splitting took place at Arizona State University in 2006.

- Titanium dioxide is also used as a material in the memristor, a new electronic circuit element. It can be employed for solar energy conversion based on dye, polymer, or quantum dot sensitized nanocrystalline TiO2 solar cells using conjugated polymers as solid electrolytes.

- Synthetic single crystals and films of TiO2 are used as a semiconductor, and also in Bragg-stack style dielectric mirrors due to the high refractive index of TiO2 (2.5–2.9).

Health and safety

| The neutrality of this article is disputed. Relevant discussion may be found on the talk page. Please do not remove this message until conditions to do so are met. (March 2011) (Learn how and when to remove this message) |

Titanium dioxide is incompatible with strong reducing agents and strong acids. Violent or incandescent reactions occur with molten metals that are very electropositive, e.g. aluminium, calcium, magnesium, potassium, sodium, zinc and lithium.

Titanium dioxide accounts for 70% of the total production volume of pigments worldwide. It is widely used to provide whiteness and opacity to products such as paints, plastics, papers, inks, foods, and toothpastes. It is also used in cosmetic and skin care products, and it is present in almost every sunblock, where it helps protect the skin from ultraviolet light.

Many sunscreens use nanoparticle titanium dioxide (along with nanoparticle zinc oxide) which does get absorbed into the skin. The effects on human health are not yet well understood. Nevertheless, allergy to topical application has been confirmed.

Titanium dioxide dust, when inhaled, has been classified by the International Agency for Research on Cancer (IARC) as an IARC Group 2B carcinogen, meaning it is possibly carcinogenic to humans. The findings of the IARC are based on the discovery that high concentrations of pigment-grade (powdered) and ultrafine titanium dioxide dust caused respiratory tract cancer in rats exposed by inhalation and intratracheal instillation. The series of biological events or steps that produce the rat lung cancers (e.g. particle deposition, impaired lung clearance, cell injury, fibrosis, mutations and ultimately cancer) have also been seen in people working in dusty environments. Therefore, the observations of cancer in animals were considered, by IARC, as relevant to people doing jobs with exposures to titanium dioxide dust. For example, titanium dioxide production workers may be exposed to high dust concentrations during packing, milling, site cleaning and maintenance, if there are insufficient dust control measures in place. However, the human studies conducted so far do not suggest an association between occupational exposure to titanium dioxide and an increased risk for cancer. The safety of the use of nano-particle sized titanium dioxide, which can penetrate the body and reach internal organs, has been criticized. Studies have also found that titanium dioxide nanoparticles cause inflammatory response and genetic damage in mice. There is some evidence the rare disease Yellow nail syndrome may be caused by titanium, either implanted for medical reasons or through eating various foods containing titanium dioxide.

Bundschuh et al. from the University Koblenz-Landau have found that waterflea (or daphnia) (a common test for mutagenicity) is damaged into the second generation when swimming in Water containing TiO2 nanoparticles.

The molecular mechanism by which TiO2 induces cancer is unclear. In 2012, Yanglong Zhu, John W. Eaton and Chi Li, on the basis of molecular research, suggested that cell cytotoxicity due to TiO2 results from the interaction between TiO2 nanoparticles and the lysosomal compartment, i.e., independently of the known apoptotic signalling pathways.

See also

- Dye-sensitized solar cell

- Noxer, a building material incorporating TiO2.

- Timeline of hydrogen technologies

- Surface properties of transition metal oxides

References

- ^ Zumdahl, Steven S. (2009). Chemical Principles 6th Ed. Houghton Mifflin Company. p. A23. ISBN 0-618-94690-X.

- El, Goresy; Chen, M; Dubrovinsky, L; Gillet, P; Graup, G (2001). "An ultradense polymorph of rutile with seven-coordinated titanium from the Ries crater". Science. 293 (5534): 1467–70. doi:10.1126/science.1062342. PMID 11520981.

- El Goresy, Ahmed; Chen, Ming; Gillet, Philippe; Dubrovinsky, Leonid; Graup, GüNther; Ahuja, Rajeev (2001). "A natural shock-induced dense polymorph of rutile with α-PbO2 structure in the suevite from the Ries crater in Germany". Earth and Planetary Science Letters. 192 (4): 485. Bibcode:2001E&PSL.192..485E. doi:10.1016/S0012-821X(01)00480-0.

- Greenwood, Norman N.; Earnshaw, Alan (1984). Chemistry of the Elements. Oxford: Pergamon Press. pp. 1117–19. ISBN 978-0-08-022057-4.

- Marchand R., Brohan L., Tournoux M. (1980). "A new form of titanium dioxide and the potassium octatitanate K2Ti8O17". Materials Research Bulletin. 15 (8): 1129–1133. doi:10.1016/0025-5408(80)90076-8.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - Latroche, M; Brohan, L; Marchand, R; Tournoux, (1989). "New hollandite oxides: TiO2(H) and K0.06TiO2". Journal of Solid State Chemistry. 81 (1): 78–82. Bibcode:1989JSSCh..81...78L. doi:10.1016/0022-4596(89)90204-1.

{{cite journal}}: CS1 maint: extra punctuation (link) - Akimoto, J.; Gotoh, Y.; Oosawa, Y.; Nonose, N.; Kumagai, T.; Aoki, K.; Takei, H. (1994). "Topotactic Oxidation of Ramsdellite-Type Li0.5TiO2, a New Polymorph of Titanium Dioxide: TiO2(R)". Journal of Solid State Chemistry. 113 (1): 27–36. Bibcode:1994JSSCh.113...27A. doi:10.1006/jssc.1994.1337.

- Simons, P. Y.; Dachille, F. (1967). "The structure of TiO2II, a high-pressure phase of TiO2". Acta Crystallographica. 23 (2): 334–336. doi:10.1107/S0365110X67002713.

- Sato H. , Endo S, Sugiyama M, Kikegawa T, Shimomura O, Kusaba K (1991). "Baddeleyite-Type High-Pressure Phase of TiO2". Science. 251 (4995): 786–788. Bibcode:1991Sci...251..786S. doi:10.1126/science.251.4995.786. PMID 17775458.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - Dubrovinskaia N A, Dubrovinsky L S., Ahuja R, Prokopenko V B., Dmitriev V., Weber H.-P., Osorio-Guillen J. M., Johansson B (2001). "Experimental and Theoretical Identification of a New High-Pressure TiO2 Polymorph". Phys. Rev. Lett. 87 (27 Pt 1): 275501. Bibcode:2001PhRvL..87A5501D. doi:10.1103/PhysRevLett.87.275501. PMID 11800890.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - Mattesini M, de Almeida J. S., Dubrovinsky L., Dubrovinskaia L, Johansson B., Ahuja R. (2004). "High-pressure and high-temperature synthesis of the cubic TiO2 polymorph". Phys. Rev. B. 70 (21): 212101. Bibcode:2004PhRvB..70u2101M. doi:10.1103/PhysRevB.70.212101.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Dubrovinsky, LS; Dubrovinskaia, NA; Swamy, V; Muscat, J; Harrison, NM; Ahuja, R; Holm, B; Johansson, B (2001). "Materials science: The hardest known oxide". Nature. 410 (6829): 653–654. Bibcode:2001Natur.410..653D. doi:10.1038/35070650. PMID 11287944.

{{cite journal}}: More than one of|author=and|last1=specified (help) - Oganov A.R., Lyakhov A.O. (2010). "Towards the theory of hardness of materials". J. of Superhard Materials. 32 (3): 143–147. doi:10.3103/S1063457610030019.

- Y. Al-Khatatbeh, K. K. M. Lee and B. Kiefer (2009). "High-pressure behavior of TiO2 as determined by experiment and theory". Phys. Rev. B. 79 (13): 134114. Bibcode:2009PhRvB..79m4114A. doi:10.1103/PhysRevB.79.134114.

- Nishio-Hamane D., Shimizu A., Nakahira R., Niwa K., Sano-Furukawa A., Okada T., Yagi T., Kikegawa T. (2010). "The stability and equation of state for the cotunnite phase of TiO2 up to 70 GPa". Phys. Chem. Minerals. 37 (3): 129–136. Bibcode:2010PCM....37..129N. doi:10.1007/s00269-009-0316-0.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - Emsley, John (2001). Nature's Building Blocks: An A–Z Guide to the Elements. Oxford: Oxford University Press. pp. 451–53. ISBN 0-19-850341-5.

- Banfield, J. F., Veblen, D. R., and Smith, D. J. (1991). "The identification of naturally occurring TiO2 (B) by structure determination using high-resolution electron microscopy, image simulation, and distance–least–squares refinement" (PDF). American Mineralogist. 76: 343.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - Winkler, Jochen (2003). Titanium Dioxide. Hannover: Vincentz Network. pp. 30-31. ISBN 3-87870-148-9.

- "Titanium Dioxide Manufacturing Processes". Millennium Inorganic Chemicals. Archived from the original on 2007-08-14. Retrieved 2007-09-05.

- Winkler, Jochen (2003). Titanium Dioxide. Hannover: Vincentz Network. p. 32. ISBN 3-87870-148-9.

- Mogilevsky, Gregory; Chen, Qiang; Kleinhammes, Alfred; Wu, Yue (2008). "The structure of multilayered titania nanotubes based on delaminated anatase". Chemical Physics Letters. 460 (4–6): 517–520. Bibcode:2008CPL...460..517M. doi:10.1016/j.cplett.2008.06.063.

- Graham Armstrong, A. Robert Armstrong, Jesús Canales and Peter G. Bruce (2005). "Nanotubes with the TiO2-B structure". Chemical Communications (19): 2454. doi:10.1039/B501883H. PMID 15886768.

{{cite journal}}: More than one of|pages=and|page=specified (help)CS1 maint: multiple names: authors list (link) - Gong, Dawei; Grimes, Craig A.; Varghese, Oomman K.; Hu, Wenchong; Singh, R. S.; Chen, Zhi; Dickey, Elizabeth C. (2011). "Titanium oxide nanotube arrays prepared by anodic oxidation". Journal of Materials Research. 16 (12): 3331. Bibcode:2001JMatR..16.3331G. doi:10.1557/JMR.2001.0457.

- Winkler, Jochen (2003). Titanium Dioxide. Hannover: Vincentz Network. p. 5. ISBN 3-87870-148-9.

- Phillips, Lance G. and Barbano, David M. "The Influence of Fat Substitutes Based on Protein and Titanium Dioxide on the Sensory Properties of Lowfat Milk" (PDF). Journal of Dairy Science. 80 (11): 2726.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - Les, Caren B. (November 2008) Light spells doom for bacteria. Photonics.com

- Winkler, Jochen (2003). Titanium Dioxide. Hannover: Vincentz Network. p. 5. ISBN 3-87870-148-9.

- Kurtoglu M. E., Longenbach T., Gogotsi Y. (2011). "Preventing Sodium Poisoning of Photocatalytic TiO2 Films on Glass by Metal Doping". International Journal of Applied Glass Science. 2 (2): 108–116. doi:10.1111/j.2041-1294.2011.00040.x.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ "Japan Nanonet Bulletin – 44th Issue – May 12, 2005: Discovery and applications of photocatalysis —Creating a comfortable future by making use of light energy"

- Fujishima, Akira; Honda, Kenichi (1972). "Electrochemical Photolysis of Water at a Semiconductor Electrode". Nature. 238 (5358): 37–8. Bibcode:1972Natur.238...37F. doi:10.1038/238037a0. PMID 12635268.

- "Carbon-doped titanium dioxide is an effective photocatalyst". Advanced Ceramics Report. 1 December 2003.

This carbon-doped titanium dioxide is highly efficient; under artificial visible light, it breaks down chlorophenol five times more efficiently than the nitrogen-doped version.

- Cheap, Clean Ways to Produce Hydrogen for Use in Fuel Cells? A Dash of Disorder Yields a Very Efficient Photocatalyst. Sciencedaily (2011-01-28)

- Hogan, Jenny (2004-02-04) Smog-busting paint soaks up noxious gases. New Scientist.

- TIME's Best Inventions of 2008. (2008-10-31).

- Winkler, Jochen (2003). Titanium Dioxide. Hannover: Vincentz Network. pp. 115-116. ISBN 3-87870-148-9.

- Konstantinou, Ioannis K; Albanis, Triantafyllos A (2004). "TiO2-assisted photocatalytic degradation of azo dyes in aqueous solution: Kinetic and mechanistic investigations" (PDF). Applied Catalysis B: Environmental. 49: 1. doi:10.1016/j.apcatb.2003.11.010.

- "Titanium Oxide for High-Density Data Storage". Research. Retrieved May 24, 2010.

- Jones, BJ; Vergne, MJ; Bunk, DM; Locascio, LE; Hayes, MA (2007). "Cleavage of Peptides and Proteins Using Light-Generated Radicals from Titanium Dioxide". Anal. Chem. 79 (4): 1327–1332. doi:10.1021/ac0613737. PMID 17297930.

{{cite journal}}: More than one of|author=and|last1=specified (help) - Lewis, Nathan. "Nanocrystalline TiO2". Research. California Institute of Technology. Retrieved October 9, 2009.

- M. D. Earle (1942). "The Electrical Conductivity of Titanium Dioxide". Physical Review. 61 (1–2): 56. Bibcode:1942PhRv...61...56E. doi:10.1103/PhysRev.61.56.

- Paschotta, Rüdiger. "Bragg Mirrors". Encyclopedia of Laser Physics and Technology. RP Photonics. Retrieved May 1, 2009.

- Lide, D. R., ed. (2005). CRC Handbook of Chemistry and Physics (86th ed.). Boca Raton (FL): CRC Press. ISBN 0-8493-0486-5.

- Occupational Health Services, Inc. (31 May 1988). "Hazardline". New York: Occupational Health Services, Inc.

{{cite news}}:|format=requires|url=(help) - Sax, N.I.; Lewis, Richard J., Sr. (2000). Dangerous Properties of Industrial Materials. Vol. III (10th ed.). New York: Van Nostrand Reinhold. p. 3279. ISBN 978-0-471-35407-9.

{{cite book}}:|access-date=requires|url=(help)CS1 maint: multiple names: authors list (link) - "Manufactured Nanomaterials and Sunscreens: Top Reasons for Precaution" (PDF). August 19, 2009. Retrieved April 12, 2010.

- "Nano-tech sunscreen presents potential health risk". ABC News. December 18, 2008. Retrieved April 12, 2010.

- "Nano World: Nanoparticle toxicity tests". Physorg.com. 2006-04-05. Retrieved April 12, 2010.

- Shaw, T; Simpson, B; Wilson, B; Oostman, H; Rainey, D; Storrs, F (2010). "True photoallergy to sunscreens is rare despite popular belief". Dermatitis. 21 (4). American Contact Dermatitis Society: 185–98. PMID 20646669.

- "Titanium dioxide" (PDF). 93. International Agency for Research on Cancer. 2006.

{{cite journal}}: Cite journal requires|journal=(help) - Kutal, C., Serpone, N. (1993). Photosensitive Metal Organic Systems: Mechanistic Principles and Applications. American Chemical Society, Washington D.C. ISBN 0841225273

- "Suncream may be linked to Alzheimer's disease, say experts". Daily Mail. London. 2009-08-24. Retrieved 2009-08-25.

- "Nanoparticles Used in Common Household Items Cause Genetic Damage in Mice". 2009-11-17. Retrieved 2009-11-17.

- Yazdi, A. S.; Guarda, G.; Riteau, N.; Drexler, S. K.; Tardivel, A.; Couillin, I.; Tschopp, J. (2010). "Nanoparticles activate the NLR pyrin domain containing 3 (Nlrp3) inflammasome and cause pulmonary inflammation through release of IL-1 and IL-1". Proceedings of the National Academy of Sciences. 107 (45): 19449–54. Bibcode:2010PNAS..10719449Y. doi:10.1073/pnas.1008155107. PMC 2984140. PMID 20974980.

- Berglund F, Carlmark B (2011). "Titanium, Sinusitis, and the Yellow Nail Syndrome". Biol. Trace Elem. Res. 143 (1): 1–7.

{{cite journal}}: Unknown parameter|month=ignored (help) - Attention: This template ({{cite doi}}) is deprecated. To cite the publication identified by doi:10.1371/journal.pone.0048956, please use {{cite journal}} (if it was published in a bona fide academic journal, otherwise {{cite report}} with

|doi=10.1371/journal.pone.0048956instead. - Attention: This template ({{cite doi}}) is deprecated. To cite the publication identified by doi:10.1371/journal.pone.0050607, please use {{cite journal}} (if it was published in a bona fide academic journal, otherwise {{cite report}} with

|doi=10.1371/journal.pone.0050607instead.

External links

- International Chemical Safety Card 0338

- "Nano-Oxides, Inc. – Nano Powders, LEGIT information on Titanium Dioxide TiO2" (PDF). www.nano-oxides.com. Retrieved November2008.

{{cite web}}: Check date values in:|accessdate=(help) - NIOSH Pocket Guide to Chemical Hazards

- "Fresh doubt over America map", bbc.co.uk, 30 July 2002

- Titanium Dioxide Classified as Possibly Carcinogenic to Humans, 2007 (if inhaled as a powder)

- A description of TiO2 photocatalysis

- Crystal structures of the three forms of TiO2

- "Architecture in Italy goes green", Elisabetta Povoledo, International Herald Tribune, November 22, 2006

- "A Concrete Step Toward Cleaner Air", Bruno Giussani, BusinessWeek.com, November 8, 2006

- "Titanium Dioxide Classified as Possibly Carcinogenic to Humans", Canadian Centre for Occupational Health and Safety, August, 2006

- Sunscreen in the Sky? Reflective Particles May Combat Warming

- Titanium and titanium dioxide production data (US and World)

| Titanium compounds | |||||

|---|---|---|---|---|---|

| Titanium(II) |

| ||||

| Titanium(III) |

| ||||

| Titanium(IV) |

| ||||

| Sunscreening agents approved by the US FDA or other agencies | |

|---|---|

| |

| UVA filters | |

| UVB filters |

|

| UVA+UVB filters | |

| See also: Photoprotection, Sun protective clothing, Sun tanning, and Sunburn | |