| Revision as of 13:47, 1 March 2022 editClueBot NG (talk | contribs)Bots, Pending changes reviewers, Rollbackers6,439,296 editsm Reverting possible vandalism by 195.194.178.40 to version by Qwerfjkl (bot). Report False Positive? Thanks, ClueBot NG. (4140911) (Bot)Tag: Rollback← Previous edit | Latest revision as of 23:42, 17 December 2024 edit undo104.50.107.127 (talk)No edit summaryTags: Mobile edit Mobile web edit | ||

| (48 intermediate revisions by 36 users not shown) | |||

| Line 1: | Line 1: | ||

| {{Short description|Iterative design and management method used in business}} | {{Short description|Iterative design and management method used in business}} | ||

| {{Other uses}} | {{Other uses}} | ||

| ] | |||

| '''PDCA''' |

'''PDCA''' or '''plan–do–check–act''' (sometimes called '''plan–do–check–adjust''') is an ] and management method used in business for the control and ] of processes and products.<ref>{{Cite book |last=Tague |first=Nancy R. |title=The quality toolbox |date=2005 |publisher=] |isbn=978-0873896399 |edition=2nd |location=Milwaukee |pages=390–392 |chapter=Plan–Do–Study–Act cycle |oclc=57251077 |chapter-url=http://asq.org/learn-about-quality/project-planning-tools/overview/pdca-cycle.html |orig-year=1995}}</ref> It is also known as the '''] cycle''', or the '''control circle'''/'''cycle'''. Another version of this PDCA cycle is OPDCA.<ref>Foresight University, The Foresight Guide, Shewhart's Learning and Deming's Quality Cycle, </ref> The added stands for ''observation'' or as some versions say: "Observe the current condition." This emphasis on observation and current condition has currency with the literature on ] and the ].<ref name="Toyota Kata">{{Cite book |last=Rother |first=Mike |title=Toyota kata: managing people for improvement, adaptiveness, and superior results |title-link=Toyota Kata |date=2010 |publisher=] |isbn=978-0071635233 |location=New York |oclc=318409119 |author-link=Mike Rother}}</ref> The PDCA cycle, with Ishikawa's changes, can be traced back to S. Mizuno of the ] in 1959.<ref name=":0" /> | ||

| The PDCA cycle is also known as PDSA cycle (where S stands for ''study''). It was an early means of representing the task areas of traditional quality management. The cycle is sometimes referred to as the Shewhart / Deming cycle since it originated with physicist Walter Shewhart at the ] in the 1920s. W. Edwards Deming modified the Shewhart cycle in the 1940s and subsequently applied it to management practices in Japan in the 1950s.<ref>{{Cite web |title=18.2.1 The Deming Cycle (PDCA Cycle) and the Shewhart Cycle |url=https://opess.ethz.ch/course/section-18-2/18-2-1-the-deming-cycle-pdca-cycle-and-the-shewhart-cycle/ |access-date=2023-04-17 |language=en-GB}}</ref> | |||

| Deming found that the focus on Check is more about the implementation of a change, with success or failure. His focus was on predicting the results of an improvement effort, Study of the actual results, and comparing them to possibly revise the theory. | |||

| ==Meaning== | ==Meaning== | ||

| ⚫ | ] | ||

| ] | |||

| ⚫ | ] | ||

| ===Plan === | ===Plan === | ||

| Line 14: | Line 18: | ||

| ===Check=== | ===Check=== | ||

| During the check phase, the data and results gathered from the do phase are evaluated. Data is compared to the expected outcomes to see any similarities and differences. The testing process is also evaluated to see if there were any changes from the original test created during the planning phase. If the data is placed in a chart it can make it easier to see any trends if the |

During the check phase, the data and results gathered from the do phase are evaluated. Data is compared to the expected outcomes to see any similarities and differences. The testing process is also evaluated to see if there were any changes from the original test created during the planning phase. If the data is placed in a chart it can make it easier to see any trends if the plan–do–check–act cycle is conducted multiple times. This helps to see what changes work better than others and if said changes can be improved as well. | ||

| Example: ] |

Example: ] or ]s | ||

| ===Act=== | ===Act=== | ||

| Also called " |

Also called "adjust", this act phase is where a process is improved. Records from the "do" and "check" phases help identify issues with the process. These issues may include problems, non-conformities, opportunities for improvement, inefficiencies, and other issues that result in outcomes that are evidently less-than-optimal. Root causes of such issues are investigated, found, and eliminated by modifying the process. Risk is re-evaluated. At the end of the actions in this phase, the process has better instructions, standards, or goals. Planning for the next cycle can proceed with a better baseline. Work in the next do phase should not create a recurrence of the identified issues; if it does, then the action was not effective. | ||

| ==About== | ==About== | ||

| Plan–do–check–act is associated with ], who is considered by many to be the father of modern ]; however, he used PDSA (Plan-Do-Study-Act) and referred to it as the "Shewhart cycle".<ref>{{Cite journal |last1=Pruitt |first1=W. Frazier |last2=Imam |first2=S.M. Waqas |title=Expert Answers: April 2021 {{!}} ASQ |url=https://asq.org/quality-progress/articles/expert-answers-april-2021?id=eb030f131fdc4da78030a62e57a97f68 |website=asq.org |volume=54 |issue=4 |page=6}}</ref> The PDSA cycle was used to create the model of know-how transfer process,<ref>{{Cite journal |last1=Dubickis |first1=Mikus |last2=Gaile-Sarkane |first2=Elīna |date=December 2017 |title=Transfer of know-how based on learning outcomes for development of open innovation |journal=Journal of Open Innovation: Technology, Market, and Complexity |volume=3 |issue=1 |pages=4 |doi=10.1186/s40852-017-0053-4 |doi-access=free|hdl=10419/176539 |hdl-access=free }}</ref> and other models.<ref>{{Cite web |last=Dubberly |first=Hugh |date=2008 |title=How do you design?: a compendium of models |url=http://www.dubberly.com/articles/how-do-you-design.html |access-date=2017-10-21 |website=dubberly.com |orig-year=2004}}</ref> | |||

| The concept of PDCA is based on the ], as developed from the work of ] ('']'', 1620). The scientific method can be written as "hypothesis–experiment–evaluation" or as "plan–do–check". ] described manufacture under "control"—under statistical control—as a three-step process of specification, production, and inspection.<ref name="Shewhart 1939">{{ |

The concept of PDCA is based on the ], as developed from the work of ] ('']'', 1620). The scientific method can be written as "hypothesis–experiment–evaluation" or as "plan–do–check". ] described manufacture under "control"—under statistical control—as a three-step process of specification, production, and inspection.<ref name="Shewhart 1939">{{Cite book |last=Shewhart |first=Walter Andrew |title=Statistical method from the viewpoint of quality control |publisher=Dover |year=1986 |isbn=978-0486652320 |location=New York |oclc=13822053 |author-link=Walter A. Shewhart |orig-year=1939}} Reprint. Originally published: Washington, DC: Graduate School of the Department of Agriculture, 1939.</ref>{{rp|45}} He also specifically related this to the scientific method of hypothesis, experiment, and evaluation. Shewhart says that the statistician "must help to change the demand by showing how to close up the tolerance range and to improve the quality of goods."<ref name="Shewhart 1939" />{{rp|48}} Clearly, Shewhart intended the analyst to take action based on the conclusions of the evaluation. According to Deming, during his lectures in Japan in the early 1950s, the Japanese participants shortened the steps to the now traditional ''plan, do, check, act''.<ref name=":0">{{Cite book |last=Deming |first=W. Edwards |url=https://archive.org/details/outofcrisis000demi |title=Out of the crisis |publisher=], Center for Advanced Engineering Study |year=1986 |isbn=978-0911379013 |location=Cambridge, MA |page= |oclc=13126265 |author-link=W. Edwards Deming |url-access=registration}}</ref> Deming preferred ''plan, do, study, act'' because "study" has connotations in English closer to Shewhart's intent than "check".<ref name="MoenNorman">{{Cite web |last1=Moen |first1=Ronald |last2=Norman |first2=Clifford |title=Evolution of the PDCA cycle |url=http://www.westga.edu/~dturner/PDCA.pdf |access-date=1 October 2011 |website=westga.edu |publisher=Paper delivered to the Asian Network for Quality Conference in Tokyo on September 17, 2009}}</ref> | ||

| ]A fundamental principle of the scientific method and |

] | ||

| A fundamental principle of the scientific method and plan–do–check–act is iteration—once a hypothesis is confirmed (or negated), executing the cycle again will extend the knowledge further. Repeating the PDCA cycle can bring its users closer to the goal, usually a perfect operation and output.<ref name="MoenNorman" /> | |||

| Plan–do–check–act (and other forms of scientific problem solving) is also known as a system for developing critical thinking. At Toyota this is also known as "Building people before building cars".<ref name="Liker">{{Cite book |last=Liker |first=Jeffrey K. |url=https://archive.org/details/toyotaway14manag00like |title=The Toyota way: 14 management principles from the world's greatest manufacturer |publisher=] |year=2004 |isbn=978-0071392310 |location=New York |oclc=54005437}}</ref> Toyota and other ] companies propose that an engaged, problem-solving workforce using PDCA in a culture of critical thinking is better able to innovate and stay ahead of the competition through rigorous problem solving and the subsequent innovations.<ref name="Liker" /> | |||

| Deming continually emphasized iterating towards an improved system, hence PDCA should be |

Deming continually emphasized iterating towards an improved system, hence PDCA should be implemented in spirals of increasing knowledge of the system that converge on the ultimate goal, each cycle closer than the previous.<ref>{{Cite web |title=PDSA Cycle - The W. Edwards Deming Institute |url=https://deming.org/explore/pdsa/ |access-date=2023-11-30 |website=deming.org/ |language=en-US}}</ref> One can envision an open coil spring, with each loop being one cycle of the scientific method, and each complete cycle indicating an increase in our knowledge of the system under study. This approach is based on the belief that our knowledge and skills are limited, but improving. Especially at the start of a project, key information may not be known; the PDCA—scientific method—provides feedback to justify guesses (hypotheses) and increase knowledge. Rather than enter "]" to get it perfect the first time, it is better to be approximately right than exactly wrong. With improved knowledge, one may choose to refine or alter the goal (ideal state). The aim of the PDCA cycle is to bring its users closer to whatever goal they choose.<ref name="Toyota Kata" />{{rp|160}} | ||

| When PDCA is used for complex projects or products with a certain controversy, checking with external stakeholders should happen before the Do stage, since changes to projects and products that are already in detailed design can be costly; this is also seen as Plan-Check-Do-Act.{{Citation needed|date=October 2017}} | When PDCA is used for complex projects or products with a certain controversy, checking with external stakeholders should happen before the Do stage, since changes to projects and products that are already in detailed design can be costly; this is also seen as Plan-Check-Do-Act.{{Citation needed|date=October 2017}} | ||

| The rate of change, that is, the rate of improvement, is a key competitive factor in today's world.{{Citation needed|date=October 2017}} PDCA allows for major "jumps" in performance ("breakthroughs" often desired in a Western approach), as well as ] (frequent small improvements).<ref>https://www.agilealliance.org/wp-content/uploads/2016/01/PDCA.pdf </ref> In the United States a PDCA approach is usually associated with a sizable project involving numerous people's time,{{Citation needed|date=October 2017}} and thus managers want to see large "breakthrough" improvements to justify the effort expended. However, the scientific method and PDCA apply to all sorts of projects and improvement activities.<ref name="Toyota Kata" />{{rp|76}} | |||

| ==See also== | ==See also== | ||

| {{Div col|colwidth=22em}} | {{Div col|colwidth=22em}} | ||

| * ], a business-focused framework for IT management and governance | |||

| ⚫ | * |

||

| * ] | * ], sequence of steps used on a repeated basis | ||

| * ] (''define, measure, analyze, improve and control''), an improvement cycle originally from Six Sigma process improvement system | |||

| * ] | |||

| ⚫ | *] | ||

| * ], model of military and law enforcement intelligence processing | |||

| * ] | * ] | ||

| * ] | * ] | ||

| * ] | * ] | ||

| * ] | * ], a teaching improvement process | ||

| * ] | * ] | ||

| * ] (''observe–orient–decide–act loop''), feedback loop used at operational level in combat operations | |||

| * ] | * ] | ||

| * ] | * ] | ||

| * ] (closed loop management system) | * ] (closed loop management system) | ||

| * ] | * ] | ||

| ⚫ | * ] | ||

| * ] | * ] | ||

| * ] | * ] | ||

| ⚫ | * ] | ||

| * ] | |||

| {{Div col end}} | {{Div col end}} | ||

| Line 61: | Line 68: | ||

| ==Further reading== | ==Further reading== | ||

| {{Commons category|PDCA}} | {{Commons category|PDCA}} | ||

| * {{ |

* {{Cite book |last=Kolesar |first=Peter J. |title=W. Edwards Deming: critical evaluations in business and management |date=2005 |publisher=] |isbn=9780415323888 |editor-last=Wood |editor-first=John C. |volume=2 |location=New York |pages=87–107 |chapter=What Deming told the Japanese in 1950 |oclc=55738077 |editor-last2=Wood |editor-first2=Michael C. |chapter-url=https://books.google.com/books?id=H6NYwPCKRWQC&pg=PA87 |orig-year=1994}} Reprint. Originally published: ''Quality Management Journal'' 2(1) (1994): 9–24. | ||

| * {{ |

* {{Cite book |last1=Langley |first1=Gerald J. |title=The improvement guide: a practical approach to enhancing organizational performance |last2=Moen |first2=Ronald D. |last3=Nolan |first3=Kevin M. |last4=Nolan |first4=Thomas W. |last5=Norman |first5=Clifford L. |last6=Provost |first6=Lloyd P. |date=2009 |publisher=] |isbn=9780470192412 |edition=2nd |location=San Francisco |oclc=236325893 |orig-year=1996}} | ||

| * {{ |

* {{Cite book |last=Shewhart |first=Walter Andrew |title=Economic control of quality of manufactured product |publisher=] |year=1980 |isbn=978-0873890762 |location=Milwaukee |oclc=7543940 |author-link=Walter A. Shewhart |orig-year=1931}} 50th anniversary commemorative reissue. Originally published: New York: Van Nostrand, 1931. | ||

| {{Lean manufacturing tools}} | {{Lean manufacturing tools}} | ||

| Line 69: | Line 76: | ||

| ] | ] | ||

| ] | |||

| ] | |||

| ] | |||

Latest revision as of 23:42, 17 December 2024

Iterative design and management method used in business For other uses, see PDCA (disambiguation).

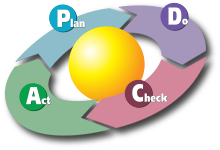

PDCA or plan–do–check–act (sometimes called plan–do–check–adjust) is an iterative design and management method used in business for the control and continual improvement of processes and products. It is also known as the Shewhart cycle, or the control circle/cycle. Another version of this PDCA cycle is OPDCA. The added stands for observation or as some versions say: "Observe the current condition." This emphasis on observation and current condition has currency with the literature on lean manufacturing and the Toyota Production System. The PDCA cycle, with Ishikawa's changes, can be traced back to S. Mizuno of the Tokyo Institute of Technology in 1959.

The PDCA cycle is also known as PDSA cycle (where S stands for study). It was an early means of representing the task areas of traditional quality management. The cycle is sometimes referred to as the Shewhart / Deming cycle since it originated with physicist Walter Shewhart at the Bell Telephone Laboratories in the 1920s. W. Edwards Deming modified the Shewhart cycle in the 1940s and subsequently applied it to management practices in Japan in the 1950s.

Deming found that the focus on Check is more about the implementation of a change, with success or failure. His focus was on predicting the results of an improvement effort, Study of the actual results, and comparing them to possibly revise the theory.

Meaning

Plan

Establish objectives and processes required to deliver the desired results.

Do

Carry out the objectives from the previous step.

Check

During the check phase, the data and results gathered from the do phase are evaluated. Data is compared to the expected outcomes to see any similarities and differences. The testing process is also evaluated to see if there were any changes from the original test created during the planning phase. If the data is placed in a chart it can make it easier to see any trends if the plan–do–check–act cycle is conducted multiple times. This helps to see what changes work better than others and if said changes can be improved as well.

Example: Gap analysis or appraisals

Act

Also called "adjust", this act phase is where a process is improved. Records from the "do" and "check" phases help identify issues with the process. These issues may include problems, non-conformities, opportunities for improvement, inefficiencies, and other issues that result in outcomes that are evidently less-than-optimal. Root causes of such issues are investigated, found, and eliminated by modifying the process. Risk is re-evaluated. At the end of the actions in this phase, the process has better instructions, standards, or goals. Planning for the next cycle can proceed with a better baseline. Work in the next do phase should not create a recurrence of the identified issues; if it does, then the action was not effective.

About

Plan–do–check–act is associated with W. Edwards Deming, who is considered by many to be the father of modern quality control; however, he used PDSA (Plan-Do-Study-Act) and referred to it as the "Shewhart cycle". The PDSA cycle was used to create the model of know-how transfer process, and other models.

The concept of PDCA is based on the scientific method, as developed from the work of Francis Bacon (Novum Organum, 1620). The scientific method can be written as "hypothesis–experiment–evaluation" or as "plan–do–check". Walter A. Shewhart described manufacture under "control"—under statistical control—as a three-step process of specification, production, and inspection. He also specifically related this to the scientific method of hypothesis, experiment, and evaluation. Shewhart says that the statistician "must help to change the demand by showing how to close up the tolerance range and to improve the quality of goods." Clearly, Shewhart intended the analyst to take action based on the conclusions of the evaluation. According to Deming, during his lectures in Japan in the early 1950s, the Japanese participants shortened the steps to the now traditional plan, do, check, act. Deming preferred plan, do, study, act because "study" has connotations in English closer to Shewhart's intent than "check".

A fundamental principle of the scientific method and plan–do–check–act is iteration—once a hypothesis is confirmed (or negated), executing the cycle again will extend the knowledge further. Repeating the PDCA cycle can bring its users closer to the goal, usually a perfect operation and output.

Plan–do–check–act (and other forms of scientific problem solving) is also known as a system for developing critical thinking. At Toyota this is also known as "Building people before building cars". Toyota and other lean manufacturing companies propose that an engaged, problem-solving workforce using PDCA in a culture of critical thinking is better able to innovate and stay ahead of the competition through rigorous problem solving and the subsequent innovations.

Deming continually emphasized iterating towards an improved system, hence PDCA should be implemented in spirals of increasing knowledge of the system that converge on the ultimate goal, each cycle closer than the previous. One can envision an open coil spring, with each loop being one cycle of the scientific method, and each complete cycle indicating an increase in our knowledge of the system under study. This approach is based on the belief that our knowledge and skills are limited, but improving. Especially at the start of a project, key information may not be known; the PDCA—scientific method—provides feedback to justify guesses (hypotheses) and increase knowledge. Rather than enter "analysis paralysis" to get it perfect the first time, it is better to be approximately right than exactly wrong. With improved knowledge, one may choose to refine or alter the goal (ideal state). The aim of the PDCA cycle is to bring its users closer to whatever goal they choose.

When PDCA is used for complex projects or products with a certain controversy, checking with external stakeholders should happen before the Do stage, since changes to projects and products that are already in detailed design can be costly; this is also seen as Plan-Check-Do-Act.

The rate of change, that is, the rate of improvement, is a key competitive factor in today's world. PDCA allows for major "jumps" in performance ("breakthroughs" often desired in a Western approach), as well as kaizen (frequent small improvements). In the United States a PDCA approach is usually associated with a sizable project involving numerous people's time, and thus managers want to see large "breakthrough" improvements to justify the effort expended. However, the scientific method and PDCA apply to all sorts of projects and improvement activities.

See also

- COBIT, a business-focused framework for IT management and governance

- Decision cycle, sequence of steps used on a repeated basis

- DMAIC (define, measure, analyze, improve and control), an improvement cycle originally from Six Sigma process improvement system

- BADIR

- Intelligence cycle, model of military and law enforcement intelligence processing

- Kolb's experiential learning

- Lean manufacturing

- Learning cycle

- Lesson study, a teaching improvement process

- Monitoring and evaluation

- OODA loop (observe–orient–decide–act loop), feedback loop used at operational level in combat operations

- Performance management

- Quality storyboard

- Robert S. Kaplan (closed loop management system)

- Six Sigma

- Software development process

- Theory of constraints

- Total security management

References

- Tague, Nancy R. (2005) . "Plan–Do–Study–Act cycle". The quality toolbox (2nd ed.). Milwaukee: ASQ Quality Press. pp. 390–392. ISBN 978-0873896399. OCLC 57251077.

- Foresight University, The Foresight Guide, Shewhart's Learning and Deming's Quality Cycle,

- ^ Rother, Mike (2010). Toyota kata: managing people for improvement, adaptiveness, and superior results. New York: McGraw-Hill. ISBN 978-0071635233. OCLC 318409119.

- ^ Deming, W. Edwards (1986). Out of the crisis. Cambridge, MA: Massachusetts Institute of Technology, Center for Advanced Engineering Study. p. 88. ISBN 978-0911379013. OCLC 13126265.

- "18.2.1 The Deming Cycle (PDCA Cycle) and the Shewhart Cycle". Retrieved 2023-04-17.

- Pruitt, W. Frazier; Imam, S.M. Waqas. "Expert Answers: April 2021 | ASQ". asq.org. 54 (4): 6.

- Dubickis, Mikus; Gaile-Sarkane, Elīna (December 2017). "Transfer of know-how based on learning outcomes for development of open innovation". Journal of Open Innovation: Technology, Market, and Complexity. 3 (1): 4. doi:10.1186/s40852-017-0053-4. hdl:10419/176539.

- Dubberly, Hugh (2008) . "How do you design?: a compendium of models". dubberly.com. Retrieved 2017-10-21.

- ^ Shewhart, Walter Andrew (1986) . Statistical method from the viewpoint of quality control. New York: Dover. ISBN 978-0486652320. OCLC 13822053. Reprint. Originally published: Washington, DC: Graduate School of the Department of Agriculture, 1939.

- ^ Moen, Ronald; Norman, Clifford. "Evolution of the PDCA cycle" (PDF). westga.edu. Paper delivered to the Asian Network for Quality Conference in Tokyo on September 17, 2009. Retrieved 1 October 2011.

- ^ Liker, Jeffrey K. (2004). The Toyota way: 14 management principles from the world's greatest manufacturer. New York: McGraw-Hill. ISBN 978-0071392310. OCLC 54005437.

- "PDSA Cycle - The W. Edwards Deming Institute". deming.org/. Retrieved 2023-11-30.

- https://www.agilealliance.org/wp-content/uploads/2016/01/PDCA.pdf

Further reading

- Kolesar, Peter J. (2005) . "What Deming told the Japanese in 1950". In Wood, John C.; Wood, Michael C. (eds.). W. Edwards Deming: critical evaluations in business and management. Vol. 2. New York: Routledge. pp. 87–107. ISBN 9780415323888. OCLC 55738077. Reprint. Originally published: Quality Management Journal 2(1) (1994): 9–24.

- Langley, Gerald J.; Moen, Ronald D.; Nolan, Kevin M.; Nolan, Thomas W.; Norman, Clifford L.; Provost, Lloyd P. (2009) . The improvement guide: a practical approach to enhancing organizational performance (2nd ed.). San Francisco: Jossey-Bass. ISBN 9780470192412. OCLC 236325893.

- Shewhart, Walter Andrew (1980) . Economic control of quality of manufactured product. Milwaukee: American Society for Quality. ISBN 978-0873890762. OCLC 7543940. 50th anniversary commemorative reissue. Originally published: New York: Van Nostrand, 1931.

| Lean manufacturing tools | |

|---|---|