| Revision as of 14:08, 2 March 2007 editClicketyclack (talk | contribs)11,654 edits Fixing links to disambiguation pages using AWB← Previous edit | Latest revision as of 19:36, 14 December 2024 edit undoStebanoid (talk | contribs)88 editsNo edit summary | ||

| (594 intermediate revisions by more than 100 users not shown) | |||

| Line 1: | Line 1: | ||

| {{Short description|Electric motor}} | |||

| {{cleanup|December 2006}} | |||

| '''Doubly fed electric machines''', '''Doubly fed induction generator''' (DFIG), or '''slip-ring generators''', are ]s or ]s, where both the ] windings and ] windings are separately connected to equipment outside the machine. | |||

| By feeding adjustable frequency ] to the ]s, the ] can be made to rotate, allowing variation in motor or generator speed. This is useful, for instance, for generators used in ]s.<ref>{{cite web |title=Generators for wind turbines Standard slip ring generator series for doubly-fed concept from 1.5-3.5 MW |publisher=] |date=2014 |url=http://new.abb.com/docs/default-source/ewea-doc/generators-for-wind-turbines-standard-slip-ring-generator-series-for-doubly-fed-concept.pdf |access-date=April 24, 2018}}</ref> Additionally, ]-based wind turbines offer the ability to control ] and ].<ref>M. J. Harandi, S. G. Liasi and M. T. Bina, "," 2019 International Power System Conference (PSC), Tehran, Iran, 2019, pp. 181-187, {{doi|10.1109/PSC49016.2019.9081565}}.</ref><ref>M. Niraula and L. Maharjan, “Variable stator frequency control of stand-alone DFIG with diode rectified output”, 5th International symposium on environment-friendly energies and applications (EFEA), 2018.</ref> | |||

| '''Doubly-fed ''electric machines''''' (i.e., ]s or ]s) belong to a category of electric machines that incorporate two multiphase winding sets of similar power rating that have independent means of excitation. An electronic controller conditions bi-directional, speed synchronized, and multiphase electrical power to at least one of the winding sets. The sum of the power ratings of the multiphase winding sets determine the total electro-mechanical conversion power rating of the machine. As a result, doubly-fed electric machines are synchronous electric machines by nature with both winding sets actively participating in the energy conversion process (i.e., doubly-fed). Uniquely, doubly-fed electric machines can operate at constant torque to twice synchronous speed for a given frequency of excitation with each active winding set rated at half the total power of the machine (i.e., contiguous operation between sub-synchronous through super-synchronous speed range). Theoretically, the electronic controller is comparably less expensive, more efficient, and more compact than electronic controllers of other electric machine because only the power of the rotating (or moving) active winding set is controlled, which is half the total power output (or less) of the electric machine. However, Doubly-Fed Electric Machines are very sensitive to the synchronous relationship between speed and excitation frequency and as a result, are susceptible to instability without introducing extraordinary means of control. Like any synchronous machine, losing synchronism will result in alternating torque pulsation and other related consequences. The ], the ], and the so-called ] are the only examples of doubly-fed electric machines. Like all synchronous electric machines or any state-of-art efficient electric machines, including the brushless DC or Permanent Magnet electric machines, doubly-fed electric machines require electronic control for practical operation and should be considered an electric machine system or more appropriately, an adjustable speed drive. Although sometimes described as doubly-fed electric machines, the wound-rotor induction machine (slip-energy recovery) and the field-excited synchronous machine are singly-fed electric machines because only one winding set actively participates in the energy conversion process. All electric machines are categorized as either ]s or Doubly-Fed Electric Machines. | |||

| ==Introduction== | |||

| '''DFIG''' is an abbreviation for Double Fed Induction Generator, a generating principle widely used in ]s. It is based on an ] with wound rotor and brushes for access to the rotor. | |||

| ] | |||

| Doubly fed electrical generators are similar to ] ]s, but have additional features which allow them to run at speeds slightly above or below their natural synchronous speed. This is useful for large ]s, because wind speed can change suddenly. When a gust of wind hits a wind turbine, the blades try to speed up, but a ] is locked to the speed of the ] and cannot speed up. So large forces are developed in the hub, gearbox, and generator as the power grid pushes back. This causes wear and damage to the mechanism. If the turbine is allowed to speed up immediately when hit by a wind gust, the stresses are lower with the power from the wind gust still being converted to useful electricity. | |||

| One approach to allowing wind turbine speed to vary is to accept whatever frequency the generator produces, convert it to DC, and then convert it to AC at the desired output frequency using an ]. This is common for small house and farm wind turbines. But the inverters required for megawatt-scale wind turbines are large and expensive. | |||

| ⚫ | ] | ||

| Doubly fed generators are another solution to this problem. Instead of the usual ] fed with DC, and an ] winding where the generated electricity comes out, there are two three-phase windings, one stationary and one rotating, both separately connected to equipment outside the generator. Thus, the term ''doubly fed'' is used for this kind of machines. | |||

| The principle is that it connects to the grid with a back-to-back ] source converter which controls the excitation system. This is in order to decouple the mechanical and electrical ] ]. By controlling the frequency delivered to the rotor it is possible to keep the frequency out of the generator on a stable level independently of the generators turning speed. | |||

| One winding is directly connected to the output, and produces 3-phase AC power at the desired grid frequency. The other winding (traditionally called the field, but here both windings can be outputs) is connected to 3-phase AC power at variable frequency. This input power is adjusted in frequency and phase to compensate for changes in speed of the turbine.<ref>{{cite journal |url=http://web.mit.edu/kirtley/binlustuff/literature/wind%20turbine%20sys/DFIGinWindTurbine.pdf |title=Doubly Fed Induction Generator Systems for Wind Turbines |author1=S. MÜLLER |author2=S. |display-authors=etal |publisher=IEEE |journal=IEEE Industry Applications Magazine |volume=8 |issue=3 |pages=26–33 |date=2002|doi=10.1109/2943.999610 }}</ref> | |||

| Adjusting the frequency and phase requires an AC to DC to AC converter. This is usually constructed from very large ] semiconductors. The converter is bidirectional, and can pass power in either direction. Power can flow from this winding as well as from the output winding.<ref>L. Wei, R. J. Kerkman, R. A. Lukaszewski, H. Lu and Z. Yuan, "Analysis of IGBT power cycling capabilities used in Doubly Fed Induction Generator wind power system," 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, 2010, pp. 3076-3083, {{doi|10.1109/ECCE.2010.5618396}}.</ref> | |||

| ==History== | |||

| With its origins in ] with multiphase winding sets on the rotor and stator, respectively, which were invented by ] in 1888,<ref>{{cite web |url=http://ethw.org/Power_electronics |title=Power electronics - Engineering and Technology History Wiki |website=ethw.org}}</ref> the rotor winding set of the doubly fed electric machine is connected to a selection of resistors via multiphase slip rings for starting. However, the slip power was lost in the resistors. Thus means to increase the efficiency in variable speed operation by recovering the slip power were developed. In Krämer (or Kraemer) drives the rotor was connected to an AC and DC machine set that fed a DC machine connected to the shaft of the slip ring machine.<ref>Leonhard, W.: Control of Electrical Drives. 2nd Ed. Springer 1996, 420 pages. {{ISBN|3-540-59380-2}}.</ref> Thus the slip power was returned as mechanical power and the drive could be controlled by the excitation currents of the DC machines. The drawback of the Krämer drive is that the machines need to be overdimensioned in order to cope with the extra circulating power. This drawback was corrected in the ] drive where the slip power is fed back to the AC grid by motor generator sets.<ref>{{Cite journal | doi=10.1109/T-AIEE.1932.5056029| title=Automatic Control for Variable Ratio Frequency Converters| year=1932| last1=Shively| first1=E. K.| last2=Whitlow| first2=Geo. S.| journal=Transactions of the American Institute of Electrical Engineers| volume=51| pages=121–127| s2cid=51636516}}</ref><ref>{{Cite journal | doi=10.1109/T-AIEE.1942.5058524| title=A Study of the Modified Kramer or Asynchronous-Synchronous Cascade Variable-Speed Drive| year=1942| last1=Liwschitz| first1=M. M.| last2=Kilgore| first2=L. A.| journal=Transactions of the American Institute of Electrical Engineers| volume=61| issue=5| pages=255–260| s2cid=51642497}}</ref> | |||

| The rotating machinery used for the rotor supply was heavy and expensive. Improvement in this respect was the static Scherbius drive where the rotor was connected to a rectifier-inverter set constructed first by ]-based devices and later on with semiconductor diodes and thyristors. In the schemes using a rectifier the power flow was possible only out of the rotor because of the uncontrolled rectifier. Moreover, only sub-synchronous operation as a motor was possible. | |||

| Another concept using static frequency converter had a '']'' connected between the rotor and the AC grid. The cycloconverter can feed power in both directions and thus the machine can be run both sub- and oversynchronous speeds. Large cycloconverter-controlled, doubly fed machines have been used to run single phase generators feeding {{frac|16|2|3}} Hz railway grid in Europe.<ref>{{Cite book | doi=10.1109/RRCON.1997.581349| isbn=0-7803-3854-5| chapter=Modern rotary converters for railway applications| title=Proceedings of the 1997 IEEE/ASME Joint Railroad Conference| year=1997| last1=Pfeiffer| first1=A.| last2=Scheidl| first2=W.| last3=Eitzmann| first3=M.| last4=Larsen| first4=E.| pages=29–33| s2cid=110505314}}</ref> Cycloconverter powered machines can also run the turbines in pumped storage plants.<ref> EPE Conference 2003, Toulouse.</ref> | |||

| Today the frequency changer used in applications up to few tens of megawatts consists of two back to back connected '']'' inverters. | |||

| Several brushless concepts have also been developed in order to get rid of the slip rings that require maintenance. | |||

| ==Doubly fed induction generator== | |||

| Doubly fed induction generator (DFIG), a generating principle widely used in ]s. It is based on an ] with a multiphase wound rotor and a multiphase ] assembly with brushes for access to the rotor windings. It is possible to avoid the multiphase slip ring assembly, but there are problems with efficiency, cost and size. A better alternative is a brushless wound-rotor doubly fed electric machine.<ref>{{cite journal |title=Overview of research and development status of brushless doubly-fed machine system |publisher=] |journal=Chinese Journal of Electrical Engineering |volume=2 |issue=2 |date=December 2016}}</ref> | |||

| ⚫ | ] | ||

| The principle of the DFIG is that stator windings are connected to the grid and rotor winding are connected to the converter via slip rings and back-to-back ] source converter that controls both the rotor and the grid currents. Thus ] ] can freely differ from the grid frequency (50 or 60 Hz). By using the converter to control the rotor currents, it is possible to adjust the active and reactive power fed to the grid from the stator independently of the generator's turning speed. The control principle used is either the two-axis current ] or ] (DTC).<ref>{{US patent|6448735}}</ref> DTC has turned out to have better stability than current vector control especially when high reactive currents are required from the generator.<ref>{{cite journal |doi=10.1002/we.254 |volume=11 |issue=1 |title=About the active and reactive power measurements in unsymmetrical voltage dip ride-through testing |year=2008 |journal=Wind Energy |pages=121–131 |last1=Niiranen |first1=Jouko|bibcode=2008WiEn...11..121N }}</ref> | |||

| The doubly fed generator rotors are typically wound with 2 to 3 times the number of turns of the stator. This means that the rotor voltages will be higher and currents respectively lower. Thus in the typical ±30% operational speed range around the synchronous speed, the rated current of the converter is accordingly lower which leads to a lower cost of the converter. The drawback is that controlled operation outside the operational speed range is impossible because of the higher than rated rotor voltage. Further, the voltage transients due to the grid disturbances (three- and two-phase voltage dips, especially) will also be magnified. In order to prevent high rotor voltages (and high currents resulting from these voltages) from destroying the ]s and ]s of the converter, a protection circuit (called ]) is used.<ref name= Crowbar_LVRT/> | |||

| The crowbar will short-circuit the rotor windings through a small resistance when excessive currents or voltages are detected. In order to be able to continue the operation as quickly as possible an ]<ref>an ]: for example {{US patent|7164562}}</ref> has to be used. The active crowbar can remove the rotor short in a controlled way and thus the rotor side converter can be started only after 20–60{{nbsp}}ms from the start of the grid disturbance when the remaining voltage stays above 15% of the nominal voltage. Thus, it is possible to generate reactive current to the grid during the rest of the voltage dip and in this way help the grid to recover from the fault. For zero voltage ], it is common to wait until the dip ends because it is otherwise not possible to know the phase angle where the reactive current should be injected.<ref>{{Cite book | doi=10.1109/PES.2008.4596687 | isbn=978-1-4244-1905-0| chapter=Low voltage ride-through analysis of 2 MW DFIG wind turbine - grid code compliance validations| title=2008 IEEE Power and Energy Society General Meeting - Conversion and Delivery of Electrical Energy in the 21st Century| year=2008| last1=Seman| first1=Slavomir| last2=Niiranen| first2=Jouko| last3=Virtanen| first3=Reijo| last4=Matsinen| first4=Jari-Pekka| pages=1–6| s2cid=41973249}}</ref> | |||

| As a summary, a doubly fed induction machine is a wound-rotor doubly fed electric machine and has several advantages over a conventional induction machine in wind power applications. First, as the rotor circuit is controlled by a power electronics converter, the induction generator is able to both import and export ]. This has important consequences for ] and allows the machine to support the grid during severe voltage disturbances (]; LVRT).<ref name= Crowbar_LVRT>M. J. Harandi, S. Ghaseminejad Liasi, E. Nikravesh and M. T. Bina, "An Improved Control Strategy for DFIG Low Voltage Ride-Through Using Optimal Demagnetizing method," 2019 10th International Power Electronics, Drive Systems and Technologies Conference (PEDSTC), Shiraz, Iran, 2019, pp. 464-469, {{doi|10.1109/PEDSTC.2019.8697267}}.</ref> Second, the control of the rotor voltages and currents enables the induction machine to remain ] with the grid while the wind turbine speed varies. A variable speed wind turbine utilizes the available wind resource more efficiently than a fixed speed wind turbine, especially during light wind conditions. Third, the cost of the converter is low when compared with other variable speed solutions because only a fraction of the mechanical power, typically 25–30%, is fed to the grid through the converter, the rest being fed to grid directly from the stator. The efficiency of the DFIG is very good for the same reason. | |||

| ==See also== | ==See also== | ||

| *] | |||

| *] | |||

| ==References== | |||

| {{reflist}} | |||

| ==External links== | |||

| * {{cite journal |last=Dufour |first=Christian |author2=Bélanger, Jean |year=2004 |url=http://www.opal-rt.com/sites/default/files/technical_papers/dufour_windturbinepaper2004.pdf |title=Real-Time Simulation of Doubly Fed Induction Generator for Wind Turbine Applications |access-date=2011-02-17 |archive-url=https://web.archive.org/web/20110105201507/http://www.opal-rt.com/sites/default/files/technical_papers/dufour_windturbinepaper2004.pdf |archive-date=2011-01-05 |url-status=dead }} | |||

| * {{cite journal |url=http://www-control.eng.cam.ac.uk/~pcr20/papers/roberts_BDFM_dissertation_2005.pdf |title=Study of Brushless Doubly-Fed (Induction) Machines; Contributions in Machine Analysis, Design and Control |first=Paul C. |last=Roberts |year=2004 |publisher=Emmanuel College, University of Cambridge |url-status=dead |archive-url=https://web.archive.org/web/20130319104947/http://www-control.eng.cam.ac.uk/~pcr20/papers/roberts_BDFM_dissertation_2005.pdf |archive-date=2013-03-19 }} | |||

| {{electric motor}} | |||

| {{DEFAULTSORT:Doubly Fed Electric Machine}} | |||

| ] | |||

| ] | ] | ||

| ] | ] | ||

Latest revision as of 19:36, 14 December 2024

Electric motorDoubly fed electric machines, Doubly fed induction generator (DFIG), or slip-ring generators, are electric motors or electric generators, where both the field magnet windings and armature windings are separately connected to equipment outside the machine.

By feeding adjustable frequency AC power to the field windings, the magnetic field can be made to rotate, allowing variation in motor or generator speed. This is useful, for instance, for generators used in wind turbines. Additionally, DFIG-based wind turbines offer the ability to control active and reactive power.

Introduction

Doubly fed electrical generators are similar to AC electrical generators, but have additional features which allow them to run at speeds slightly above or below their natural synchronous speed. This is useful for large variable speed wind turbines, because wind speed can change suddenly. When a gust of wind hits a wind turbine, the blades try to speed up, but a synchronous generator is locked to the speed of the power grid and cannot speed up. So large forces are developed in the hub, gearbox, and generator as the power grid pushes back. This causes wear and damage to the mechanism. If the turbine is allowed to speed up immediately when hit by a wind gust, the stresses are lower with the power from the wind gust still being converted to useful electricity.

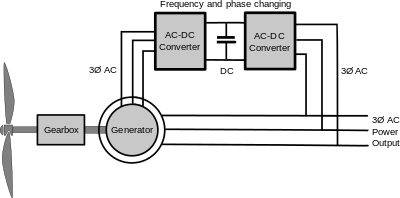

One approach to allowing wind turbine speed to vary is to accept whatever frequency the generator produces, convert it to DC, and then convert it to AC at the desired output frequency using an inverter. This is common for small house and farm wind turbines. But the inverters required for megawatt-scale wind turbines are large and expensive.

Doubly fed generators are another solution to this problem. Instead of the usual field winding fed with DC, and an armature winding where the generated electricity comes out, there are two three-phase windings, one stationary and one rotating, both separately connected to equipment outside the generator. Thus, the term doubly fed is used for this kind of machines.

One winding is directly connected to the output, and produces 3-phase AC power at the desired grid frequency. The other winding (traditionally called the field, but here both windings can be outputs) is connected to 3-phase AC power at variable frequency. This input power is adjusted in frequency and phase to compensate for changes in speed of the turbine.

Adjusting the frequency and phase requires an AC to DC to AC converter. This is usually constructed from very large IGBT semiconductors. The converter is bidirectional, and can pass power in either direction. Power can flow from this winding as well as from the output winding.

History

With its origins in wound rotor induction motors with multiphase winding sets on the rotor and stator, respectively, which were invented by Nikola Tesla in 1888, the rotor winding set of the doubly fed electric machine is connected to a selection of resistors via multiphase slip rings for starting. However, the slip power was lost in the resistors. Thus means to increase the efficiency in variable speed operation by recovering the slip power were developed. In Krämer (or Kraemer) drives the rotor was connected to an AC and DC machine set that fed a DC machine connected to the shaft of the slip ring machine. Thus the slip power was returned as mechanical power and the drive could be controlled by the excitation currents of the DC machines. The drawback of the Krämer drive is that the machines need to be overdimensioned in order to cope with the extra circulating power. This drawback was corrected in the Scherbius drive where the slip power is fed back to the AC grid by motor generator sets.

The rotating machinery used for the rotor supply was heavy and expensive. Improvement in this respect was the static Scherbius drive where the rotor was connected to a rectifier-inverter set constructed first by mercury arc-based devices and later on with semiconductor diodes and thyristors. In the schemes using a rectifier the power flow was possible only out of the rotor because of the uncontrolled rectifier. Moreover, only sub-synchronous operation as a motor was possible.

Another concept using static frequency converter had a cycloconverter connected between the rotor and the AC grid. The cycloconverter can feed power in both directions and thus the machine can be run both sub- and oversynchronous speeds. Large cycloconverter-controlled, doubly fed machines have been used to run single phase generators feeding 16+2⁄3 Hz railway grid in Europe. Cycloconverter powered machines can also run the turbines in pumped storage plants.

Today the frequency changer used in applications up to few tens of megawatts consists of two back to back connected IGBT inverters.

Several brushless concepts have also been developed in order to get rid of the slip rings that require maintenance.

Doubly fed induction generator

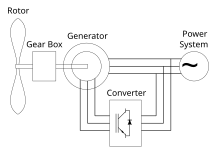

Doubly fed induction generator (DFIG), a generating principle widely used in wind turbines. It is based on an induction generator with a multiphase wound rotor and a multiphase slip ring assembly with brushes for access to the rotor windings. It is possible to avoid the multiphase slip ring assembly, but there are problems with efficiency, cost and size. A better alternative is a brushless wound-rotor doubly fed electric machine.

The principle of the DFIG is that stator windings are connected to the grid and rotor winding are connected to the converter via slip rings and back-to-back voltage source converter that controls both the rotor and the grid currents. Thus rotor frequency can freely differ from the grid frequency (50 or 60 Hz). By using the converter to control the rotor currents, it is possible to adjust the active and reactive power fed to the grid from the stator independently of the generator's turning speed. The control principle used is either the two-axis current vector control or direct torque control (DTC). DTC has turned out to have better stability than current vector control especially when high reactive currents are required from the generator.

The doubly fed generator rotors are typically wound with 2 to 3 times the number of turns of the stator. This means that the rotor voltages will be higher and currents respectively lower. Thus in the typical ±30% operational speed range around the synchronous speed, the rated current of the converter is accordingly lower which leads to a lower cost of the converter. The drawback is that controlled operation outside the operational speed range is impossible because of the higher than rated rotor voltage. Further, the voltage transients due to the grid disturbances (three- and two-phase voltage dips, especially) will also be magnified. In order to prevent high rotor voltages (and high currents resulting from these voltages) from destroying the insulated-gate bipolar transistors and diodes of the converter, a protection circuit (called crowbar) is used.

The crowbar will short-circuit the rotor windings through a small resistance when excessive currents or voltages are detected. In order to be able to continue the operation as quickly as possible an active crowbar has to be used. The active crowbar can remove the rotor short in a controlled way and thus the rotor side converter can be started only after 20–60 ms from the start of the grid disturbance when the remaining voltage stays above 15% of the nominal voltage. Thus, it is possible to generate reactive current to the grid during the rest of the voltage dip and in this way help the grid to recover from the fault. For zero voltage ride through, it is common to wait until the dip ends because it is otherwise not possible to know the phase angle where the reactive current should be injected.

As a summary, a doubly fed induction machine is a wound-rotor doubly fed electric machine and has several advantages over a conventional induction machine in wind power applications. First, as the rotor circuit is controlled by a power electronics converter, the induction generator is able to both import and export reactive power. This has important consequences for power system stability and allows the machine to support the grid during severe voltage disturbances (low-voltage ride-through; LVRT). Second, the control of the rotor voltages and currents enables the induction machine to remain synchronized with the grid while the wind turbine speed varies. A variable speed wind turbine utilizes the available wind resource more efficiently than a fixed speed wind turbine, especially during light wind conditions. Third, the cost of the converter is low when compared with other variable speed solutions because only a fraction of the mechanical power, typically 25–30%, is fed to the grid through the converter, the rest being fed to grid directly from the stator. The efficiency of the DFIG is very good for the same reason.

See also

References

- "Generators for wind turbines Standard slip ring generator series for doubly-fed concept from 1.5-3.5 MW" (PDF). ABB. 2014. Retrieved April 24, 2018.

- M. J. Harandi, S. G. Liasi and M. T. Bina, "Compensating Stator Transient Flux during Symmetric and Asymmetric Faults using Virtual Flux based on Demagnetizing Current in DFIG Wind Turbines," 2019 International Power System Conference (PSC), Tehran, Iran, 2019, pp. 181-187, doi:10.1109/PSC49016.2019.9081565.

- M. Niraula and L. Maharjan, “Variable stator frequency control of stand-alone DFIG with diode rectified output”, 5th International symposium on environment-friendly energies and applications (EFEA), 2018.

- S. MÜLLER; S.; et al. (2002). "Doubly Fed Induction Generator Systems for Wind Turbines" (PDF). IEEE Industry Applications Magazine. 8 (3). IEEE: 26–33. doi:10.1109/2943.999610.

- L. Wei, R. J. Kerkman, R. A. Lukaszewski, H. Lu and Z. Yuan, "Analysis of IGBT power cycling capabilities used in Doubly Fed Induction Generator wind power system," 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, 2010, pp. 3076-3083, doi:10.1109/ECCE.2010.5618396.

- "Power electronics - Engineering and Technology History Wiki". ethw.org.

- Leonhard, W.: Control of Electrical Drives. 2nd Ed. Springer 1996, 420 pages. ISBN 3-540-59380-2.

- Shively, E. K.; Whitlow, Geo. S. (1932). "Automatic Control for Variable Ratio Frequency Converters". Transactions of the American Institute of Electrical Engineers. 51: 121–127. doi:10.1109/T-AIEE.1932.5056029. S2CID 51636516.

- Liwschitz, M. M.; Kilgore, L. A. (1942). "A Study of the Modified Kramer or Asynchronous-Synchronous Cascade Variable-Speed Drive". Transactions of the American Institute of Electrical Engineers. 61 (5): 255–260. doi:10.1109/T-AIEE.1942.5058524. S2CID 51642497.

- Pfeiffer, A.; Scheidl, W.; Eitzmann, M.; Larsen, E. (1997). "Modern rotary converters for railway applications". Proceedings of the 1997 IEEE/ASME Joint Railroad Conference. pp. 29–33. doi:10.1109/RRCON.1997.581349. ISBN 0-7803-3854-5. S2CID 110505314.

- A. Bocquel, J. Janning: 4*300 MW variable speed drive for pump-storage plant application. EPE Conference 2003, Toulouse.

- "Overview of research and development status of brushless doubly-fed machine system". Chinese Journal of Electrical Engineering. 2 (2). Chinese Society for Electrical Engineering. December 2016.

- U.S. patent 6,448,735

- Niiranen, Jouko (2008). "About the active and reactive power measurements in unsymmetrical voltage dip ride-through testing". Wind Energy. 11 (1): 121–131. Bibcode:2008WiEn...11..121N. doi:10.1002/we.254.

- ^ M. J. Harandi, S. Ghaseminejad Liasi, E. Nikravesh and M. T. Bina, "An Improved Control Strategy for DFIG Low Voltage Ride-Through Using Optimal Demagnetizing method," 2019 10th International Power Electronics, Drive Systems and Technologies Conference (PEDSTC), Shiraz, Iran, 2019, pp. 464-469, doi:10.1109/PEDSTC.2019.8697267.

- an active crowbar: for example U.S. patent 7,164,562

- Seman, Slavomir; Niiranen, Jouko; Virtanen, Reijo; Matsinen, Jari-Pekka (2008). "Low voltage ride-through analysis of 2 MW DFIG wind turbine - grid code compliance validations". 2008 IEEE Power and Energy Society General Meeting - Conversion and Delivery of Electrical Energy in the 21st Century. pp. 1–6. doi:10.1109/PES.2008.4596687. ISBN 978-1-4244-1905-0. S2CID 41973249.

External links

- Dufour, Christian; Bélanger, Jean (2004). "Real-Time Simulation of Doubly Fed Induction Generator for Wind Turbine Applications" (PDF). Archived from the original (PDF) on 2011-01-05. Retrieved 2011-02-17.

{{cite journal}}: Cite journal requires|journal=(help) - Roberts, Paul C. (2004). "Study of Brushless Doubly-Fed (Induction) Machines; Contributions in Machine Analysis, Design and Control" (PDF). Emmanuel College, University of Cambridge. Archived from the original (PDF) on 2013-03-19.

{{cite journal}}: Cite journal requires|journal=(help)

| Electric machines | |

|---|---|

| |

| Components and accessories | |

| Generators | |

| Motors | |

| Motor controllers | |

| History, education, recreational use | |

| Experimental, futuristic | |

| Related topics | |

| People | |