| Revision as of 00:59, 25 December 2011 editCitation bot 1 (talk | contribs)Bots130,044 editsm Add: pages, pmc. Tweak: title, pages. Formatted dashes. You can use this bot yourself. Report bugs here.← Previous edit | Latest revision as of 02:08, 26 December 2024 edit undoKepler-1229b (talk | contribs)Extended confirmed users19,299 editsNo edit summaryTag: 2017 wikitext editor | ||

| (87 intermediate revisions by 64 users not shown) | |||

| Line 1: | Line 1: | ||

| {{Redirect|CTi|Taiwanese broadcaster which uses the CTi branding|Chung T'ien Television}} | |||

| {{Expand language|topic=|langcode=uk|otherarticle=Карбід титану|date=December 2024}} | |||

| {{chembox | {{chembox | ||

| | Verifiedfields = changed | |||

| | verifiedrevid = |

| verifiedrevid = 441066916 | ||

| | ImageFile = TiC-xtal-3D-vdW.png | | ImageFile = TiC-xtal-3D-vdW.png | ||

| | ImageSize = | | ImageSize = | ||

| | IUPACName = | | IUPACName = titanium carbide | ||

| | OtherNames = | | OtherNames = titanium(IV) carbide | ||

| | |

|Section1={{Chembox Identifiers | ||

| | CASNo_Ref = {{cascite}} | | CASNo_Ref = {{cascite|correct|CAS}} | ||

| | CASNo = 12070-08-5 | | CASNo = 12070-08-5 | ||

| | UNII_Ref = {{fdacite|correct|FDA}} | |||

| ⚫ | | PubChem = |

||

| | UNII = 7SHTGW5HBI | |||

| ⚫ | | SMILES = | ||

| ⚫ | | PubChem = 4226345 | ||

| ⚫ | | SMILES = # | ||

| | StdInChI = 1S/C.Ti/q-1;+1 | |||

| }} | }} | ||

| | |

|Section2={{Chembox Properties | ||

| | Formula = TiC | | Formula = TiC | ||

| | MolarMass = 59.89 g/mol | | MolarMass = 59.89 g/mol | ||

| Line 19: | Line 25: | ||

| | BoilingPtC = 4820 | | BoilingPtC = 4820 | ||

| | Solubility = insoluble in ] | | Solubility = insoluble in ] | ||

| | MagSus = +8.0·10<sup>−6</sup> cm<sup>3</sup>/mol | |||

| }} | }} | ||

| | |

|Section3={{Chembox Structure | ||

| | |

| CrystalStruct = ], ] | ||

| | |

| SpaceGroup = Fm<u style="text-decoration:overline">3</u>m, No. 225 | ||

| | |

| Coordination = Octahedral | ||

| }} | }} | ||

| | |

|Section7={{Chembox Hazards | ||

| | MainHazards = | | MainHazards = | ||

| | FlashPt = | | FlashPt = | ||

| | |

| AutoignitionPt = | ||

| }} | }} | ||

| }} | }} | ||

| '''Titanium carbide''', ]], is an extremely ] (] |

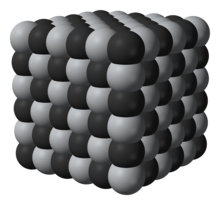

'''Titanium carbide''', ]], is an extremely ] (] 9–9.5) ] ] material, similar to ]. It has the appearance of black powder with the ] (]) ]. | ||

| It occurs in nature as a form of the very rare mineral '''{{ill|khamrabaevite|uz|Hamroboyevit}}''' ({{Langx|ru|Хамрабаевит}}) - (Ti,V,Fe)C. It was discovered in 1984 on ] in the ],<ref>{{Cite journal |last=Dunn |first=Pete J |date=1985 |title=New mineral names |url=https://pubs.geoscienceworld.org/msa/ammin/article-abstract/70/3-4/436/41735/New-Mineral-Names |journal=American Mineralogist |volume=70 |pages=1329–1335}}</ref> USSR (modern ]), near the Uzbek border. The mineral was named after Ibragim Khamrabaevich Khamrabaev, director of Geology and Geophysics of ], ]. Its crystals as found in nature range in size from 0.1 to 0.3 mm. | |||

| It is commercially used in ]s. It has the appearance of black powder with ]-] ] ]. It is mainly used in preparation of ]s, which are frequently used to ] ] materials at high cutting speed. | |||

| ==Physical properties== | |||

| ⚫ | The resistance to ], ], and ] of a ] |

||

| Titanium carbide has an ] of approximately 400 GPa and a shear modulus of 188 GPa.<ref>{{cite journal |url=http://scitation.aip.org/content/aip/journal/jap/37/10/10.1063/1.1707923 |title=Low-Temperature Elastic Properties of ZrC and TiC |last1=Chang |first1=R |last2=Graham |first2=L |date=1966 |journal=Journal of Applied Physics |volume=37|issue=10 |pages=3778–3783 |doi=10.1063/1.1707923|bibcode=1966JAP....37.3778C }}</ref> | |||

| Titanium carbide is soluble in solid ], with a range of compositions which are collectively named "titanium oxycarbide" and created by ] reduction of the oxide.<ref>{{Cite thesis |title=Production of Titanium Metal by an Electrochemical Molten Salt Process |url=https://kilthub.cmu.edu/articles/thesis/Production_of_Titanium_Metal_by_an_Electrochemical_Molten_Salt_Process/6721160/1?file=12255587 |publisher=Carnegie Mellon University |date=2017-05-01 |degree=thesis |language=en |first=Farzin |last=Fatollahi-Fard}}</ref> | |||

| ⚫ | Tool bits without tungsten content can be made of titanium carbide in ]-cobalt matrix cermet, enhancing the cutting speed, precision, and smoothness of the workpiece. |

||

| ==Manufacturing and machining== | |||

| ⚫ | |||

| ⚫ | Tool bits without tungsten content can be made of titanium carbide in ]-cobalt matrix ], enhancing the cutting speed, precision, and smoothness of the workpiece.{{citation needed|date=September 2014}} | ||

| ⚫ | The resistance to ], ], and ] of a ]–] material can be increased by adding 6–30% of titanium carbide to tungsten carbide. This forms a ] that is more ] and susceptible to breakage.{{clarify|reason=why would that be an advantage?|date=July 2015}} | ||

| The mineralogical form is very rare and called khamrabaevite - (Ti,V,Fe)C. | |||

| ⚫ | Titanium carbide can be ] with ]. | ||

| == Titanium-carbon clusters == | |||

| == Applications == | |||

| A surprisingly stable cluster with formula Ti<sub>8</sub>C<sub>12</sub><sup>+</sup>, was detected in 1992.<ref name="guo1">{{cite journal|doi=10.1126/science.255.5050.1411|year=1992|month=Mar|author=Guo, Bc; Kerns, Kp; Castleman, Aw, Jr|title=Ti8C12+-Metallo-Carbohedrenes: A New Class of Molecular Clusters?|volume=255|issue=5050|pages=1411–1413|issn=0036-8075|pmid=17801229|journal=Science}}</ref><ref name="guo2">{{cite journal|doi = 10.1126/science.256.5056.515|year = 1992|month = Apr|author = Guo, Bc; Wei, S; Purnell, J; Buzza, S; Castleman, Aw, Jr|title = Metallo-Carbohedrenes M8C12+ (M = V, Zr, Hf, and Ti): A Class of Stable Molecular Cluster Ions|volume = 256|issue = 5056|pages = 515–516|issn = 0036-8075|pmid = 17787948|journal = Science}}</ref> The 20 atoms were conjectured to be arranged as the vertices of a ], with the titanium atoms at the corners of a ] <ref name="guo1"/> However, this claim was soon disputed by ]<ref>{{cite journal|author =L Pauling| title= Molecular structure of Ti8C12 and related complexes|journal= Proc. Natl. Acad. Sci. USA|year = 1992 |volume =89| page = 8175| url =http://www.pnas.org/content/89/17/8175.full.pdf+html|doi =10.1073/pnas.89.17.8175| pmid=11607323| issue=17|pages =8175–6|pmc =49879}}</ref> who proposed an alternative arrangement — with the Ti atoms still at the corners of a cube, but with the carbon atoms pushed inwards so as to be nearly coplanar with the faces of that cube. | |||

| Titanium carbide is used in preparation of ]s, which are frequently used to ] ] materials at high cutting speed. It is also used as an abrasion-resistant surface coating on metal parts, such as ]s and watch mechanisms.<ref>{{cite journal|doi=10.1016/j.surfcoat.2018.11.060|title=Decorative black coatings on titanium surfaces based on hard bi-layered carbon coatings synthesized by carbon implantation|journal=Surface and Coatings Technology|volume=358|pages=386–393|year=2019|last1=Gupta|first1=P.|last2=Fang|first2=F.|last3=Rubanov|first3=S.|last4=Loho|first4=T.|last5=Koo|first5=A.|last6=Swift|first6=N.|last7=Fiedler|first7=H.|last8=Leveneur|first8=J.|last9=Murmu|first9=P.P.|last10=Markwitz|first10=A.|last11=Kennedy|first11=J.|s2cid=139179067|hdl=2292/46133|hdl-access=free}}</ref> Titanium carbide is also used as a ] coating for ] of ].<ref>{{cite book|url=https://books.google.com/books?id=ntWcBAAAQBAJ&q=titanium+carbide&pg=PA406|title=Manned Spacecraft Design Principles|last1=Sforza|first1=Pasquale M.|date=13 November 2015|publisher=Elsevier|page=406|language=en|access-date=4 January 2017|isbn=9780124199767}}</ref> | |||

| ] (AA7075) is almost as strong as steel, but weighs one third as much. Using thin AA7075 rods with TiC nanoparticles allows larger alloys pieces to be welded without phase-segregation induced cracks.<ref>{{Cite web|url=https://newatlas.com/welding-aa7075-aluminum-alloy/58449/|title=New welding process opens up uses for formerly un-weldable lightweight alloy|website=newatlas.com|date=13 February 2019|language=en|access-date=2019-02-18}}</ref> | |||

| == See also == | |||

| * ], a family of metal-carbon clusters including {{chem2|Ti8C12}} | |||

| ==References== | ==References== | ||

| {{Reflist}} | {{Reflist}} | ||

| {{Titanium compounds}} | {{Titanium compounds}} | ||

| ] | ] | ||

| ⚫ | ] | ||

| ⚫ | ] | ||

| ⚫ | ] | ||

| ] | ] | ||

| ⚫ | ] | ||

| ⚫ | ] | ||

| {{inorganic-compound-stub}} | |||

| ⚫ | ] | ||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

Latest revision as of 02:08, 26 December 2024

"CTi" redirects here. For Taiwanese broadcaster which uses the CTi branding, see Chung T'ien Television.You can help expand this article with text translated from the corresponding article in Ukrainian. (December 2024) Click for important translation instructions.

|

| |

| Names | |

|---|---|

| IUPAC name titanium carbide | |

| Other names titanium(IV) carbide | |

| Identifiers | |

| CAS Number | |

| 3D model (JSmol) | |

| ECHA InfoCard | 100.031.916 |

| PubChem CID | |

| UNII | |

| CompTox Dashboard (EPA) | |

InChI

| |

SMILES

| |

| Properties | |

| Chemical formula | TiC |

| Molar mass | 59.89 g/mol |

| Appearance | black powder |

| Density | 4.93 g/cm |

| Melting point | 3,160 °C (5,720 °F; 3,430 K) |

| Boiling point | 4,820 °C (8,710 °F; 5,090 K) |

| Solubility in water | insoluble in water |

| Magnetic susceptibility (χ) | +8.0·10 cm/mol |

| Structure | |

| Crystal structure | Cubic, cF8 |

| Space group | Fm3m, No. 225 |

| Coordination geometry | Octahedral |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C , 100 kPa).

| |

Titanium carbide, TiC, is an extremely hard (Mohs 9–9.5) refractory ceramic material, similar to tungsten carbide. It has the appearance of black powder with the sodium chloride (face-centered cubic) crystal structure.

It occurs in nature as a form of the very rare mineral khamrabaevite [uz] (Russian: Хамрабаевит) - (Ti,V,Fe)C. It was discovered in 1984 on Mount Arashan in the Chatkal District, USSR (modern Kyrgyzstan), near the Uzbek border. The mineral was named after Ibragim Khamrabaevich Khamrabaev, director of Geology and Geophysics of Tashkent, Uzbekistan. Its crystals as found in nature range in size from 0.1 to 0.3 mm.

Physical properties

Titanium carbide has an elastic modulus of approximately 400 GPa and a shear modulus of 188 GPa.

Titanium carbide is soluble in solid titanium oxide, with a range of compositions which are collectively named "titanium oxycarbide" and created by carbothermic reduction of the oxide.

Manufacturing and machining

Tool bits without tungsten content can be made of titanium carbide in nickel-cobalt matrix cermet, enhancing the cutting speed, precision, and smoothness of the workpiece.

The resistance to wear, corrosion, and oxidation of a tungsten carbide–cobalt material can be increased by adding 6–30% of titanium carbide to tungsten carbide. This forms a solid solution that is more brittle and susceptible to breakage.

Titanium carbide can be etched with reactive-ion etching.

Applications

Titanium carbide is used in preparation of cermets, which are frequently used to machine steel materials at high cutting speed. It is also used as an abrasion-resistant surface coating on metal parts, such as tool bits and watch mechanisms. Titanium carbide is also used as a heat shield coating for atmospheric reentry of spacecraft.

7075 aluminium alloy (AA7075) is almost as strong as steel, but weighs one third as much. Using thin AA7075 rods with TiC nanoparticles allows larger alloys pieces to be welded without phase-segregation induced cracks.

See also

- Metallocarbohedryne, a family of metal-carbon clusters including Ti8C12

References

- Dunn, Pete J (1985). "New mineral names". American Mineralogist. 70: 1329–1335.

- Chang, R; Graham, L (1966). "Low-Temperature Elastic Properties of ZrC and TiC". Journal of Applied Physics. 37 (10): 3778–3783. Bibcode:1966JAP....37.3778C. doi:10.1063/1.1707923.

- Fatollahi-Fard, Farzin (2017-05-01). Production of Titanium Metal by an Electrochemical Molten Salt Process (thesis thesis). Carnegie Mellon University.

- Gupta, P.; Fang, F.; Rubanov, S.; Loho, T.; Koo, A.; Swift, N.; Fiedler, H.; Leveneur, J.; Murmu, P.P.; Markwitz, A.; Kennedy, J. (2019). "Decorative black coatings on titanium surfaces based on hard bi-layered carbon coatings synthesized by carbon implantation". Surface and Coatings Technology. 358: 386–393. doi:10.1016/j.surfcoat.2018.11.060. hdl:2292/46133. S2CID 139179067.

- Sforza, Pasquale M. (13 November 2015). Manned Spacecraft Design Principles. Elsevier. p. 406. ISBN 9780124199767. Retrieved 4 January 2017.

- "New welding process opens up uses for formerly un-weldable lightweight alloy". newatlas.com. 13 February 2019. Retrieved 2019-02-18.

| Titanium compounds | |||||

|---|---|---|---|---|---|

| Titanium(II) |

| ||||

| Titanium(III) |

| ||||

| Titanium(IV) |

| ||||