| Revision as of 09:49, 27 April 2016 editRcfurse (talk | contribs)1 editm →Energy efficiencyTag: Visual edit← Previous edit | Latest revision as of 21:49, 9 January 2025 edit undoAndy Dingley (talk | contribs)Autopatrolled, Extended confirmed users, Pending changes reviewers, Rollbackers160,424 edits simplify wl | ||

| (537 intermediate revisions by more than 100 users not shown) | |||

| Line 1: | Line 1: | ||

| {{Short description|Type of motor vehicle transmission that automatically changes gear ratio as the vehicle moves}} | |||

| ''This is about the transmission type for cars. For other meanings of "AT", see ].'' | |||

| ] hydraulic automatic]] | |||

| ] | |||

| An '''automatic transmission''' (sometimes abbreviated '''AT''') is a multi-speed ] used in motor vehicles that does not require any input from the driver to change forward gears under normal driving conditions. | |||

| {{transmission types}} | |||

| ] | |||

| ] showing the typical positioning of an automatic transmission from the interior of an automobile]] | |||

| The 1904 Sturtevant "horseless carriage gearbox" is often considered to be the first true automatic transmission.<ref>{{cite web |url=https://www.autorepairsanantonio.com/40-automatic-transmission-history |title=Automatic Transmissions- A Brief History |website=AutoServiceExperts |year=2003|url-status=live|archive-url=https://web.archive.org/web/20200418231514/https://www.autorepairsanantonio.com/40-automatic-transmission-history |archive-date=2020-04-18}}</ref><ref name=hearst>{{cite magazine|url=https://www.caranddriver.com/research/a31884931/what-is-an-automatic-car/ |title=What is an Automatic Car?|author=Hearst Autos Research|magazine=Car and Driver |date=13 April 2020<!--from page source-->|url-status=live|archive-url=https://web.archive.org/web/20200417081714/https://www.caranddriver.com/research/a31884931/what-is-an-automatic-car/ |archive-date=2020-04-17}}</ref>{{Failed verification|date=March 2024|reason=Source 1 does not mention the Sturtevant transmission. Source 2 cites source 1.}} The first mass-produced automatic transmission is the General Motors '']'' four-speed hydraulic automatic, which was introduced in 1939. | |||

| An '''automatic transmission''', also called '''auto''', '''self-shifting transmission''', '''''n''-speed automatic''' (where ''n'' is its number of forward gear ratios), or '''AT''', is a type of ] ] that can automatically change ]s as the vehicle moves, freeing the driver from having to shift gears ]. Like other transmission systems on vehicles, it allows an ], best suited to run at a relatively high ], to provide a range of speed and torque outputs necessary for vehicular travel. The number of forward gear ratios is often expressed for manual transmissions as well (e.g., 6-speed manual). | |||

| Automatic transmissions are especially prevalent in vehicular ]s, particularly those subject to intense mechanical acceleration and frequent idle/transient operating conditions; commonly commercial/passenger/utility vehicles, such as ]es and ]s. | |||

| The most popular form found in ] is the ] automatic transmission. Similar but larger devices are also used for heavy-duty commercial and industrial vehicles and equipment. This system uses a ] in place of a friction ], and accomplishes gear changes by hydraulically locking and unlocking a system of ]. These systems have a defined set of gear ranges, often with a ] that locks the output shaft of the transmission to keep the vehicle from rolling either forward or backward. Some machines with limited speed ranges or fixed engine speeds, such as some ]s and ]s, only use a ] to provide a variable gearing of the engine to the wheels. | |||

| ==Prevalence== | |||

| Besides the traditional hydraulic automatic transmissions, there are also other types of automated transmissions, such as a ] (CVT) and ]s, that free the driver from having to shift gears manually, by using the transmission's computer to change gear, if for example the driver were ] the engine. Despite superficial similarity to other transmissions, traditional automatic transmissions differ significantly in internal operation and driver's feel from semi-automatics and CVTs. In contrast to conventional automatic transmissions, a CVT uses a belt or other torque transmission scheme to allow an "infinite" number of gear ratios instead of a fixed number of gear ratios. A semi-automatic retains a clutch like a manual transmission, but controls the clutch through ]. The ability to shift gears manually, often via paddle shifters, can also be found on certain automated transmissions (]s such as ]), semi-automatics (BMW SMG, VW Group ]), and CVTs (such as ]). | |||

| Vehicles with internal combustion engines, unlike electric vehicles, require the engine to operate in a narrow range of rates of rotation, requiring a gearbox, operated manually or automatically, to drive the wheels over a wide range of speeds. | |||

| Globally, 43% of new cars produced in 2015 were manual transmissions, falling to 37% by 2020.<ref name="Statista"/> Automatic transmissions have long been prevalent in the United States, but only started to become common in Europe much later. In Europe in 1997, only 10–12% of cars had automatic transmissions.<ref>{{cite web |url=https://gearsmagazine.com/magazine/automatic-trends-in-europe-automatic-transmissions-on-the-rise/ |title=Gears Magazine - Automatic Trends in Europe: Automatic Transmissions on the Rise}}</ref> | |||

| The obvious advantage of an automatic transmission to the driver is the lack of a clutch pedal and manual shift pattern in normal driving. This allows the driver to operate the car with as few as two limbs (possibly using assist devices to position controls within reach of usable limbs), allowing amputees and other disabled individuals to drive. The lack of manual shifting also reduces the attention and workload required inside the cabin, such as monitoring the tachometer and taking a hand off the wheel to move the shifter, allowing the driver to ideally keep both hands on the wheel at all times and to focus more on the road around him or her. Control of the car at low speeds is often easier with an automatic than a manual, due to a side effect of the clutchless fluid-coupling design called "creep" that causes the car to want to move while in a driving gear, even at idle. The primary disadvantage of the most popular hydraulic designs is reduced mechanical efficiency of the power transfer between engine and drivetrain, due to the fluid coupling connecting the engine to the gearbox. This can result in lower power/torque ratings for automatics compared to manuals with the same engine specs, as well as reduced fuel efficiency in city driving as the engine must maintain idle against the resistance of the fluid coupling. Advances in transmission and coupler design have narrowed this gap considerably, but clutch-based transmissions (manual or semi-automatic) are still preferred in sport-tuned trim levels of various production cars, as well as in many auto racing leagues. | |||

| In 1957 over 80% of new cars in the United States had automatic transmissions.<ref name="Statista">{{cite web |url=https://www.statista.com/statistics/204123/transmission-type-market-share-in-automobile-production-worldwide/ |title=Transmission type market share worldwide 2025}}</ref> Automatic transmissions have been standard in large cars since at least 1974.<ref>{{cite web |url=https://www.scaruffi.com/politics/cars.html |title=Timeline of the Automobile Industry}}</ref> By 2020 only 2.4% of new cars had manual transmissions.<ref>{{cite web |title=The Stick Shift Index: Do People Still Drive Stick Shift Cars in America? |url=https://www.carmax.com/articles/stick-shift-index |website=Carmax |access-date=4 April 2023}}</ref> Historically, automatic transmissions were less efficient, but lower fuel prices in the US made this less of a problem than in Europe.<ref>{{cite web |url=https://garagedreams.net/car-facts/why-are-automatic-cars-so-popular-in-the-united-states |title=Why Are Automatic Cars So Popular in the United States? |date=4 November 2022}}</ref> | |||

| The automatic transmission was invented in 1921 by Alfred Horner Munro of Regina, Saskatchewan, Canada, and patented under Canadian patent CA 235757 in 1923. (Munro obtained UK patent GB215669 215,669 for his invention in 1924 and US patent 1,613,525 on 4 January 1927). Being a steam engineer, Munro designed his device to use compressed air rather than hydraulic fluid, and so it lacked power and never found commercial application.<ref>{{cite web|last1=Warwick|first1=Alan|title=Who Invented the Automatic Gearbox|url=http://www.nwtgearboxes.co.uk/who-invented-the-automatic-gearbox|publisher=North West Transmissions Ltd.|accessdate=11 October 2014}}</ref> The first automatic transmission using hydraulic fluid may have been developed in 1932 by two Brazilian engineers, José Braz Araripe and Fernando Lehly Lemos; subsequently the prototype and plans were sold to General Motors who introduced it in the 1940 Oldsmobile as the ] transmission.<ref>{{cite web|last1=Co|first1=Brent|title=Of fluids and automatic transmissions|url=http://www.autoindustriya.com/auto-tech-road-safety/of-fluids-and-automatic-transmissions.html|website=Autoindustrya.com|accessdate=11 October 2014}}</ref> They were incorporated into GM-built tanks during ] and, after the war, GM marketed them as being "battle-tested."{{citation needed|date=September 2014}} However, a ] article credits ] with the invention, occurring shortly after ]. ZF's origins were in manufacturing gears for airship engines beginning in 1915; the company was founded by ].<ref></ref> | |||

| In the United Kingdom, a majority of new cars have had automatic transmissions since 2020. Several manufacturers including Mercedes and Volvo no longer sell cars with manual transmissions. The growing prevalence of automatic transmissions is attributed to the increasing number of electric and hybrid cars, and the ease of integrating it with safety systems such as ].<ref>{{cite news| last=Griffiths |first=Hugo |title=Automatics for the people: less than a third of new cars can be ordered with a manual gearbox | publisher=carwow| date=19 October 2022 |url=https://www.carwow.co.uk/news/6414/automatic-gearboxes-become-the-norm}}</ref><ref>{{cite news |last1=Grose |first1=Thomas K. |title=U.K. Motorists Shift Gears to Automatic Vehicles |url=https://www.usnews.com/news/best-countries/articles/2021-06-09/british-motorists-move-away-from-manual-transmission-vehicles |access-date=4 April 2023 |work=U.S. News & World Report |date=9 June 2021}}</ref> | |||

| == History == | |||

| Modern automatic transmissions can trace their origins to an early "]" gearbox that was developed in 1904 by the Sturtevant brothers of ], ]. This unit had two forward speeds, the ratio change being brought about by flyweights that were driven by the engine. At higher engine speeds, high gear was engaged. As the vehicle slowed down and engine RPM decreased, the gearbox would shift back to low. Unfortunately, the ] of the time wasn't up to the task, and owing to the abruptness of the gear change, the transmission would often fail without warning. | |||

| The next significant phase in the automatic transmission's development occurred in 1908 with the introduction of ]'s remarkable ]. The Model T, in addition to being cheap and reliable by the standards of the day, featured a simple, two speed plus reverse ] whose operation was manually controlled by the driver using pedals. The pedals actuated the transmission's friction elements (bands and clutches) to select the desired gear. In some respects, this type of transmission was less demanding of the driver's skills than the contemporary, unsynchronized ], but still required that the driver know when to make a shift, as well as how to get the car off to a smooth start. | |||

| In 1934, both ] and ] developed semi-automatic transmissions that were less difficult to operate than a fully manual unit. These designs, however, continued to use a ] to engage the engine with the transmission. The General Motors unit, dubbed the "Automatic Safety Transmission," was notable in that it employed a power-shifting planetary gearbox that was hydraulically controlled and was sensitive to road speed, anticipating future development. | |||

| Parallel to the development in the 1930s of an automatically shifting gearbox was ]'s work on adapting the ] to automotive use. Invented early in the 20th century, the fluid coupling was the answer to the question of how to avoid stalling the engine when the vehicle was stopped with the transmission in gear. Chrysler itself never used the fluid coupling with any of its automatic transmissions, but did use it in conjunction with a hybrid manual transmission called "]" (the similar ] used a ]). These developments in automatic gearbox and fluid coupling technology eventually culminated in the introduction in 1939 of the General Motors ], the world's first mass-produced automatic transmission. | |||

| Available as an option on 1940 ]s and later ]s, the Hydra-Matic combined a ] with three ] planetary gearsets to produce four forward speeds plus reverse. The transmission was sensitive to engine throttle position and road speed, producing fully automatic up- and down-shifting that varied according to operating conditions. | |||

| The Hydra-Matic was subsequently adopted by ] and ], and was sold to various other automakers, including ], ], ], ], and ]. It also found use during ] in some military vehicles. From 1950 to 1954, ] cars were also available with the Hydra-Matic. ] subsequently devised a four-speed fluid coupling transmission that was similar in principle to the Hydra-Matic, but of a different design. | |||

| Interestingly, the original Hydra-Matic incorporated two features which are widely emulated in today's transmissions. The Hydra-Matic's ratio spread through the four gears produced excellent "step-off" and acceleration in first, good spacing of intermediate gears, and the effect of an overdrive in fourth, by virtue of the low numerical rear axle ratio used in the vehicles of the time. In addition, in third and fourth gear, the fluid coupling only handled a portion of the engine's torque, resulting in a high degree of efficiency. In this respect, the transmission's behavior was similar to modern units incorporating a ] torque converter. | |||

| In 1956, GM introduced the "Jetaway" Hydra-Matic, which was different in design than the older model. Addressing the issue of shift quality, which was an ongoing problem with the original Hydra-Matic, the new transmission utilized two fluid couplings, the primary one that linked the transmission to the engine, and a secondary one that replaced the clutch assembly that controlled the forward gearset in the original. The result was much smoother shifting, especially from first to second gear, but with a loss in efficiency and an increase in complexity. Another innovation for this new style Hydra-Matic was the appearance of a Park position on the selector. The original Hydra-Matic, which continued in production until the mid-1960s, still used the reverse position for parking pawl engagement. | |||

| The first torque converter automatic, ]'s ], was introduced for the 1948 model year. It was followed by Packard's ] in mid-1949 and ]'s ] for the 1950 model year. Each of these transmissions had only two forward speeds, relying on the converter for additional torque multiplication. In the early 1950s, ] developed a series of three-speed torque converter automatics for ], ], ], and several other manufacturers in the US and other countries. ] was late in developing its own true automatic, introducing the two-speed torque converter ] in 1953, and the three-speed ] in 1956. The latter was the first to utilize the Simpson compound planetary gearset. | |||

| General Motors produced multiple-turbine torque converters from 1954 to 1961. These included the Twin-Turbine ] and the triple-turbine Turboglide transmissions. The shifting took place in the torque converter, rather than through pressure valves and changes in planetary gear connections. Each turbine was connected to the drive shaft through a different gear train. These phased from one ratio to another according to demand, rather than shifting. The Turboglide actually had two speed ratios in reverse, with one of the turbines rotating backwards. | |||

| By the late 1960s, most of the fluid-coupling four-speed and two-speed transmissions had disappeared in favor of three-speed units with torque converters. Also around this time, ] was removed from automatic transmission fluid.<ref></ref> By the early 1980s, these were being supplemented and eventually replaced by ]-equipped transmissions providing four or more forward speeds. Many transmissions also adopted the lock-up torque converter (a mechanical clutch locking the torque converter pump and turbine together to eliminate slip at cruising speed) to improve fuel economy. | |||

| As computerized ]s (ECUs) became more capable, much of the logic built into the transmission's valve body was offloaded to the ECU. Some manufacturers use a separate computer dedicated to the transmission called a ] (TCU), also known as the transmission control module (TCM), which share information with the engine management computer. In this case, ]s turned on and off by the computer control shift patterns and gear ratios, rather than the spring-loaded valves in the valve body. This allows for more precise control of shift points, shift quality, lower shift times, and (on some newer cars) semi-automatic control, where the driver tells the computer when to shift. The result is an impressive combination of efficiency and smoothness. Some computers even identify the driver's style and adapt to best suit it. | |||

| ==Efficiency== | |||

| ] and ] were responsible for introducing the first six-speed (the ] in the 2002 ] ] ]). ]'s ] was the first seven-speed in 2003, with ] introducing an eight-speed in 2007 on the ] 460. Derived from the ], ] unveiled a semi-automatic transmission with the torque converter replaced with a wet multi clutch called the AMG SPEEDSHIFT MCT.<ref></ref> The ] has the world's first nine-speed automatic transmission for a passenger vehicle to market. | |||

| The efficiency (power output as a percentage of input) of conventional automatic transmissions ranges from 86 to 94%. Manual transmissions are more fuel efficient than all but the newest automatic transmissions due to their inherently low parasitic losses (typically of about 4%) in addition to being cheaper to make, lighter, better performing, and of simpler mechanical design. ] worsens with lower efficiency. However, manual transmissions have the disadvantage of requiring the driver to operate the ] and change gear whenever required.<ref name="NAP">{{cite book |title=Cost, Effectiveness, and Deployment of Fuel Economy Technologies for Light-Duty Vehicles |publisher=National Academies Press |publication-place=Washington, D.C. |date=28 September 2015 |isbn=978-0-309-37388-3 |chapter-url=https://nap.nationalacademies.org/read/21744/chapter/7|chapter=5: Transmissions|doi=10.17226/21744}}</ref> | |||

| Real-world tests reported in 2022 found that in typical driving manual transmissions achieved 2 to 5% better fuel economy than automatics, increasing to 20% with an expert driver. Some laboratory tests show automatics in a better light due to the tests using a prescribed shifting pattern for manuals not always optimized for economy. However, on long highway journeys manual transmissions require maintaining a very specific cruising speed to optimise economy, making automatics preferable.<ref>{{cite web |last=Tamayo |first=Niky |title=Have automatic transmissions dethroned manuals as the fuel-economy kings? |publisher=Topgear Philippines| date=30 May 2022 |url=https://www.topgear.com.ph/features/feature-articles/manual-vs-automatic-fuel-economy-2022-a2584-20220530}}</ref> | |||

| ==Parts and operation== | |||

| ==Hydraulic automatic transmission== | |||

| {{more citations needed section|date=July 2017}} | |||

| ===Design=== | |||

| The predominant form of automatic transmission is ] operated; using a ] or torque converter, and a set of ] to provide a range of gear ratios. | |||

| ]: ] on the left, planetary gearsets in the centre, control mechanisms at the bottom]] | |||

| The most common design of automatic transmissions is the hydraulic automatic, which typically uses planetary gearsets that are operated using hydraulics.<ref>{{cite web |title=How Automatic Transmissions Work |url=https://auto.howstuffworks.com/automatic-transmission.htm |website=www.howstuffworks.com |access-date=22 November 2020 |language=en |date=29 November 2000}}</ref><ref>{{cite journal |title=What Makes Automatic Transmissions Automatic |journal=Popular Mechanics |date=February 1955 |pages=169–173 |url=https://books.google.com/books?id=390DAAAAMBAJ&q=true&pg=RA1-PA169 |access-date=22 November 2020 |publisher=Hearst Magazines |language=en}}</ref> The transmission is connected to the engine via a torque converter (or a ] prior to the 1960s), instead of the ] used by most ]s.<ref name="awnc">{{cite web|title=How does the AT work?|url=http://www.aw-nc.com/products/drivetrain/structure/index.html|website=AW North Carolina|access-date=6 October 2014|url-status=dead|archive-url=https://web.archive.org/web/20141006084301/http://www.aw-nc.com/products/drivetrain/structure/index.html|archive-date=6 October 2014}}</ref> | |||

| ] showing the major stages of a hydraulic automatic transmission: the ] (left), the ]s and ] (center), as well as hydraulic and electronic controls (bottom). ]] | |||

| ====Gearsets and shifting mechanism==== | |||

| Hydraulic automatic transmissions consist of three major components:<ref name=awnc>{{cite web|title=How does the AT work?|url=http://www.aw-nc.com/products/drivetrain/structure/index.html|website=AW North Carolina, Inc.|accessdate=6 October 2014}}</ref> | |||

| A hydraulic automatic transmission uses planetary gearsets instead of the manual transmission's design of gears lined up along input, output and intermediate shafts. To change gears, the hydraulic automatic uses a combination of internal clutches, friction bands or brake packs. These devices are used to lock certain gears, thus setting which gear ratio is in use at a given time.<ref name="ofria">{{cite web|last1=Ofria |first1=Charles |title=A short course on automatic transmissions |url=http://www.carparts.com/transmission.htm |website=CarParts.com |publisher=JC Whitney |access-date=6 October 2014 |url-status=dead |archive-url=https://web.archive.org/web/20141006082430/http://www.carparts.com/transmission.htm |archive-date=6 October 2014}}</ref> | |||

| A ] (a ratchet-like device which can ] and transmits torque in only one direction) is often used for routine gear shifts. The advantage of a sprag clutch is that it eliminates the sensitivity of timing a simultaneous clutch release/apply on two planetary gearsets, simply "taking up" the drivetrain load when actuated, and releasing automatically when the next gear's sprag clutch assumes the torque transfer. | |||

| ====]==== | |||

| A type of fluid coupling, hydraulically connecting the engine to the transmission. This takes the place of a friction ] in a manual transmission.<ref name=tracy>{{cite web|last1=Tracy|first1=David|title=This is how an automatic transmission works|url=http://jalopnik.com/this-is-how-an-automatic-transmission-works-517581894|website=Jalopnik|publisher=Gawker Media|accessdate=6 October 2014}}</ref> It transmits and decouples the engine power to the planetary gears, allowing the vehicle to come to stop with the engine still running without ].<ref name=awnc /> | |||

| The friction bands are often used for manually selected gears (such as low range or reverse) and operate on the planetary drum's circumference. Bands are not applied when the drive/overdrive range is selected, the torque being transmitted by the sprag clutches instead. | |||

| A torque converter differs from a ], in that it provides a variable amount of ] multiplication at low engine speeds, increasing breakaway acceleration. A fluid coupling works well when both the ] and ] are rotating at similar speeds, but it is very inefficient at initial acceleration, where rotational speeds are very different. This torque multiplication is accomplished with a third member in the coupling assembly known as the ], which acts to modify the fluid flow depending on the relative rotational speeds of the impeller and turbine. The stator itself does not rotate, but its vanes are so shaped that when the impeller (which is driven by the engine) is rotating at a high speed and the turbine (which receives the transmitted power) is spinning at a low speed, the fluid flow hits the vanes of the turbine in a way that multiplies the torque being applied. This causes the turbine to begin spinning faster as the vehicle accelerates (ideally), and as the relative rotational speeds equalize, the torque multiplication diminishes. Once the impeller and turbine are rotating within 10% of each other's speed, the stator ceases to function and the torque converter acts as a simple fluid coupling. | |||

| ====Planetary gears train==== | |||

| Consisting of ] as well as clutches and bands. These are the mechanical systems that provide the various ], altering the speed of rotation of the output shaft depending on which planetary gears are locked.<ref name=ofria>{{cite web|last1=Ofria|first1=Charles|title=A short course on automatic transmissions|url=http://www.carparts.com/transmission.htm|website=CarParts.com|publisher=JC Whitney|accessdate=6 October 2014}}</ref> | |||

| To effect gear changes, one of two types of clutches or bands are used to hold a particular member of the planetary gearset motionless, while allowing another member to rotate, thereby transmitting torque and producing gear reductions or overdrive ratios. These clutches are actuated by the valve body (see below), their sequence controlled by the transmission's internal programming. Principally, a type of device known as a ] or roller clutch is used for routine upshifts/downshifts. Operating much as a ratchet, it transmits torque only in one direction, free-wheeling or "overrunning" in the other. The advantage of this type of clutch is that it eliminates the sensitivity of timing a simultaneous clutch release/apply on two planetaries, simply "taking up" the drivetrain load when actuated, and releasing automatically when the next gear's sprag clutch assumes the torque transfer. The bands come into play for manually selected gears, such as low range or reverse, and operate on the planetary drum's circumference. Bands are not applied when drive/overdrive range is selected, the torque being transmitted by the sprag clutches instead. Bands are used for braking; the GM Turbo-Hydramatics incorporated this.{{Citation needed|date=April 2010}}. | |||

| ====Hydraulic controls==== | ====Hydraulic controls==== | ||

| The aforementioned friction bands and clutches are controlled using ] (ATF), which is pressurized by a pump and then directed to the appropriate bands/clutches to obtain the required gear ratio.<ref name="awnc"/><ref name="ofria"/> The ATF provides lubrication, corrosion prevention, and a hydraulic medium to transmit the power required to operate the transmission. Made from petroleum with various refinements and additives, ATF is one of the few parts of the automatic transmission that needs routine service as the vehicle ages. | |||

| Uses special ] sent under pressure by an ] to control various clutches and bands modifying the speed of the output depending on the vehicle's running condition.<ref name=awnc /><ref name=ofria /> | |||

| The ''main pump'' which pressurises the ATF is typically a gear pump mounted between the torque converter and the planetary gear set. The input for the main pump is connected to the torque converter housing, which in turn is bolted to the engine's flexplate, so the pump provides pressure whenever the engine is running. A disadvantage of this arrangement is that there is no oil pressure to operate the transmission when the engine is not running, therefore it is not possible to ] a vehicle equipped with an automatic transmission with no rear pump (aside from several automatics built prior to 1970, which also included a rear pump for towing and push-starting purposes). The pressure of the ATF is regulated by a ''governor'' connected to the output shaft, which varies the pressure depending on the vehicle speed. | |||

| The '' |

The ''valve body'' inside the transmission is responsible for directing hydraulic pressure to the appropriate bands and clutches. It receives pressurized fluid from the main pump and consists of several spring-loaded valves, check balls, and ] pistons. In older automatic transmissions, the valves use the pump pressure and the pressure from a ] on the output side (as well as other inputs, such as throttle position or the driver locking out the higher gears) to control which ratio is selected. As the vehicle and engine change speed, the difference between the pressures changes, causing different sets of valves to open and close. In more recent automatic transmissions, the valves are controlled by ].<ref name="ofria"/> These solenoids are computer-controlled, with the gear selection decided by a dedicated ] (TCU) or sometimes this function is integrated into the ] (ECU). Modern designs have replaced the centrifugal governor with an electronic speed sensor that is used as an input to the TCU or ECU. Modern transmissions also factor in the amount of load on an engine at any given time, which is determined from either the ] position or the amount of intake manifold vacuum.<ref name="ofria"/> | ||

| The multitude of parts, along with the complex design of the valve body, originally made hydraulic automatic transmissions much more expensive and time-consuming to build and repair than manual transmissions; however mass-production and developments over time have reduced this cost gap. | |||

| The hydraulic & lubricating oil, called ] (ATF), provides lubrication, corrosion prevention, and a hydraulic medium to convey mechanical power (for the operation of the transmission). Primarily made from refined petroleum, and processed to provide properties that promote smooth power transmission and increase service life, the ATF is one of the few parts of the automatic transmission that needs routine service as the vehicle ages. | |||

| ====Torque converter==== | |||

| The multitude of parts, along with the complex design of the valve body, originally made hydraulic automatic transmissions much more complicated (and expensive) to build and repair than manual transmissions. In most cars (except US family, luxury, sport-utility vehicle, and minivan models) they have usually been extra-cost options for this reason. Mass manufacturing and decades of improvement have reduced this cost gap. | |||

| {{main|Torque converter}} | |||

| ] | |||

| To provide coupling and decoupling of the engine, a modern automatic transmission uses a torque converter instead of the ] used in a manual transmission.<ref name="awnc"/><ref name="tracy">{{cite web|last1=Tracy|first1=David|title=This is how an automatic transmission works|url=http://jalopnik.com/this-is-how-an-automatic-transmission-works-517581894|website=Jalopnik|publisher=Gawker Media|access-date=6 October 2014}}</ref> | |||

| ===History=== | |||

| In some modern cars, computers use sensors on the engine to detect ] position, vehicle speed, engine speed, engine load, etc. to control the exact shift point. The computer transmits the information via ] that redirect the fluid the appropriate clutch or ] to control shifting.<ref name=ofria /> | |||

| {{globalize|section|United States|date=November 2020}} | |||

| ====1904–1939: Predecessors to the hydraulic automatic==== | |||

| ===Continuously variable transmissions=== | |||

| The 1904 Sturtevant "horseless carriage gearbox" is often considered to be the first automatic transmission for motor vehicles.<ref>{{cite web |title=The American Automobile 1861-1929 Chapter 2 |url=http://www.earlyamericanautomobiles.com/americanautomobiles2.htm |website=www.earlyamericanautomobiles.com |access-date=1 November 2020 |archive-date=22 February 2020 |archive-url=https://web.archive.org/web/20200222192744/http://www.earlyamericanautomobiles.com/americanautomobiles2.htm |url-status=dead}}</ref><ref>{{cite web |title=The Pros and Cons of Automatic Transmissions |url=https://stevesimports.com/blog/the-pros-and-cons-of-automatic-transmissions/ |website=www.stevesimports.com |access-date=1 November 2020 |language=en |date=30 September 2019}}</ref> At higher engine speeds, high gear was engaged. As the vehicle slowed down and engine speed decreased, the gearbox would shift back to low. However, the transmission was prone to sudden failure, due to the transmission being unable to withstand forces from the abrupt gear changes. | |||

| {{Main|Continuously variable transmission}} | |||

| The adoption of planetary gearsets was a significant advance towards the modern automatic transmission. One of the first transmissions to use this design was the manual transmission fitted to the 1901–1904 ] automobile.<ref name="Automotor">{{cite news |title=The Wilson-Pilcher Petrol Cars |work=The Automotor Journal |date=16 April 1904 |pages=463–468, also pp. 492–496, and pp. 519–521}}</ref> This transmission was built in the United Kingdom and used two epicyclic gears to provide four gear ratios. A foot clutch was used for standing starts, gear selection was using a hand lever, helical gears were used (to reduce noise) and the gears used a constant-mesh design. A planetary gearset was also used in the 1908 ], which was fitted with a two-speed manual transmission (without helical gears). | |||

| A fundamentally different type of automatic transmission is the ''continuously variable transmission'' or ''CVT'', which can smoothly and steplessly alter its ] by varying the diameter of a pair of ] or ]-linked ]s, ]s or cones. Some continuously variable transmissions use a ] drive — consisting of a ] and a hydraulic motor — to transmit power without gears. Some early forms, such as the Hall system (which dates back to 1896<ref>Hydraulic Variable Transmission Mechanism, John Willam Hall, GB Patents, No 7479(1896), No 22406(1901), No 442(1903) and No 4148(1907)</ref>), used a fixed displacement pump and a variable displacement motor, and were designed to provide robust variable transmission for early commercial heavy motor vehicles.<ref>"The Hall Hydraulic Variable Speed-Gear - Part 1", Automotor Journal, June 25th, 1904, pp773-777</ref> CVT designs are usually as fuel efficient as manual transmissions in city driving, but early designs lose efficiency as engine speed increases.<ref>{{cite web|url=http://www.lib.ucdavis.edu/dept/pse/resources/cvt04/papers/04CVT-56.pdf|title=CVT Speed and Efficiency Relation|publisher=UC Davis|accessdate=2012-07-05}}</ref> | |||

| An early patent for the automatic transmission was granted to Canadian inventor Alfred Horner Munro of Regina in 1923.<ref>{{cite web |last1=Government of Canada |title=Canadian Patent Database |url=http://brevets-patents.ic.gc.ca/opic-cipo/cpd/eng/patent/235757/summary.html |website=www.brevets-patents.ic.gc.ca |access-date=22 November 2020 |language=en |date=15 June 2015}}</ref> Being a steam engineer, Munro designed his device to use ] rather than ], and so it lacked power and never found commercial application.<ref>{{cite web|last1=Warwick|first1=Alan|title=Who Invented the Automatic Gearbox|date=9 April 2013 |url=http://www.nwtgearboxes.co.uk/who-invented-the-automatic-gearbox|publisher=North West Transmissions|access-date=11 October 2014}}</ref> | |||

| A slightly different approach to CVT is the concept of ''toroidal CVT'' or '']'' (IVT). These concepts provide zero and reverse gear ratios. | |||

| In 1923, a patent was approved in the United States describing the operation of a transmission where the manual shifting of gears and manual operation of a clutch was eliminated. This patent was submitted by Henry R. Hoffman from Chicago and was titled: ''Automatic Gear Shift and Speed Control''. The patent described the workings of such a transmission as "...having a series of clutches disposed intermediate the engine shaft and the differential shaft and in which the clutches are arranged to selectively engage and drive the differential shaft dependent upon the speed at which the differential shaft rotates". However, it would be over a decade later until automatic transmissions were produced in significant quantities. In the meantime, several European and British manufacturers would use ]es, a form of manual transmission which removed the reliance on the driver's skill to achieve smooth gear shifts. | |||

| ====E-CVT==== | |||

| {{main|Hybrid Synergy Drive}} | |||

| Some hybrid vehicles, notably those of ], ] and ], have an electronically controlled CVT (E-CVT). In this system, the transmission has fixed gears, but the ratio of wheel-speed to engine-speed can be continuously varied by controlling the speed of the third input to a ] using ]. | |||

| The first automatic transmission using hydraulic fluid was developed in 1932 by two Brazilian engineers, José Braz Araripe and Fernando Lehly Lemos.<ref>{{Cite web|date=2019-08-30|title=Top 10 All-Time Auto Inventions|url=https://www.inventorsdigest.com/articles/top-10-all-time-auto-inventions/|access-date=2021-03-29|website=Inventors Digest|language=en-US}}</ref><ref name="hearst"/> | |||

| ==Automatic transmission modes== | |||

| Most automatic transmissions offer the driver a certain amount of manual control over the transmission's shifts. | |||

| The evolution towards mass-produced automatic transmissions continued with the 1933–1935 ] ''Self-Shifter'' semi-automatic transmission,<ref name="hagerty.com">{{cite web |title=6 of the worst automatic transmissions ever |url=https://www.hagerty.com/media/maintenance-and-tech/6-of-the-worst-automatic-transmissions-ever/ |website=www.hagerty.com |access-date=9 August 2020 |date=8 August 2019}}</ref> which automatically shifted between two forward gears in the "Forward" mode (or between two shorter gear ratios in the "Emergency low" mode). Driver involvement was still required during normal driving, since standing starts required the driver to use the clutch pedal.<ref>{{cite web|url=http://auto.howstuffworks.com/reo-cars1.htm|title=How Reo Cars Work|date=15 June 2007|access-date=24 October 2017}}</ref> This was followed in 1937 by the ] ''Automatic Safety Transmission''. Similar in operation to the REO ''Self-Shifter'', the ''Automatic Safety Transmission'' shifted automatically between the two gear ratios available in the "Low" and "High" ranges and the clutch pedal was required for standing starts. It used a planetary gearset.<ref>{{cite web |title=The Oldsmobile automatic safety transmission operated by the short lever shown on the steering column |url=https://digitalcollections.nypl.org/items/510d47db-bb52-a3d9-e040-e00a18064a99 |website=www.nypl.org |access-date=9 August 2020 |language=en}}</ref><ref>{{cite web |title=No clutch to press! No gears to shift! |url=https://www.autonews.com/article/19970818/ANA/708180702/no-clutch-to-press-no-gears-to-shift |website=www.autonews.com |access-date=9 August 2020 |language=en |date=18 August 1997}}</ref><ref>{{cite web |title=How Oldsmobile Cars Work |url=https://auto.howstuffworks.com/oldsmobile-cars1.htm |website=www.howstuffworks.com |access-date=9 August 2020 |language=en |date=20 June 2007 |archive-date=20 September 2020 |archive-url=https://web.archive.org/web/20200920073229/https://auto.howstuffworks.com/oldsmobile-cars1.htm |url-status=dead}}</ref> The Chrysler '']'', introduced in 1939, was an optional addition to manual transmissions where a fluid coupling (similar to a torque-convertor, but without the torque multiplication) was added, to avoid the need to operate a manual clutch.<ref>{{cite web |title=The Fluid Drive torque converter |url=https://www.allpar.com/mopar/fluidrive.html |website=www.allpar.com |access-date=3 November 2020}}</ref><ref>{{cite web |title=Video: An Introduction to Chrysler Fluid Drive |url=https://www.macsmotorcitygarage.com/video-an-introduction-to-chrysler-fluid-drive/ |website=www.macsmotorcitygarage.com |access-date=3 November 2020 |date=24 October 2017}}</ref> | |||

| Conventionally, in order to select the transmission operating mode, the driver moves a selection lever located either on the steering column or on the floor (as with a manual on the floor, except that automatic selectors on the floor do not move in the same type of pattern as manual levers do). In order to select modes, or to manually select specific gear ratios, the driver must push a button in (called the shift-lock button) or pull the handle (only on column mounted shifters) out. Some vehicles position selector buttons for each mode on the cockpit instead, freeing up space on the central console. | |||

| ====1939–1964: Early hydraulic automatics==== | |||

| Vehicles conforming to US Government standards<ref> standards</ref> must have the modes ordered P-R-N-D-L (left to right, top to bottom, or clockwise). Previously, quadrant-selected automatic transmissions often used a P-N-D-L-R layout, or similar. Such a pattern led to a number of deaths and injuries owing to driver error causing unintentional gear selection, as well as the danger of having a selector (when worn) jump into reverse from low gear during ] maneuvers. | |||

| The General Motors ] became the first mass-produced automatic transmission following its introduction in 1939 (1940 model year). Available as an option in cars such as the ] and ], the Hydra-Matic combined a ] with three ] planetary gearsets to produce four forward speeds plus reverse. The transmission was sensitive to engine throttle position and road speed, producing fully automatic up- and down-shifting that varied according to operating conditions. Features of the Hydra-Matic included a wide spread of ratios (allowing both good acceleration in first gear and cruising at low engine speed in top gear) and the fluid coupling handling only a portion of the engine's torque in the top two gears (increasing fuel economy in those gears, similar to a ] torque converter). Use of the Hydra-Matic spread to other General Motors brands and then to other manufacturers starting 1948 including ], ], ], ], ] (Australia), as well as ] and ] licensing production in the UK and providing the transmission to ], ] and other UK manufacturers.<ref>{{cite web | url=https://ateupwithmotor.com/terms-technology-definitions/rolls-royce-automatic-gearbox | title=Don't Call It Hydra-Matic: The Rolls-Royce and Bentley Automatic Gearbox < Ate up with Motor | date=4 September 2022 }}</ref> During World War II, the Hydra-Matic was used in some military vehicles. | |||

| The first automatic transmission to use a torque converter (instead of a fluid coupling) was the Buick ], which was introduced for the 1948 model year. In normal driving, the Dynaflow used only the top gear, relying on the torque multiplication of the torque convertor at lower speeds. The Dynaflow was followed by the Packard ] in mid-1949 and the Chevrolet ] for the 1950 model year. Each of these transmissions had only two forward speeds, relying on the converter for additional torque multiplication. In the early 1950s, ] developed a series of three-speed torque converter automatics for car manufacturers such as American Motors, Ford and Studebaker. ] was late in developing its own true automatic, introducing the two-speed torque converter ] in 1953, and the three-speed ] in 1956. The latter was the first to utilize the Simpson compound planetary gearset. | |||

| ] showing the P-R-N--D-L modes as well as the shift lock button on the top of the lever ]] | |||

| In 1956, the General Motors Hydra-Matic (which still used a fluid coupling) was redesigned based around the use of two fluid couplings to provide smoother shifts. This transmission was called the ''Controlled Coupling Hydra-Matic'', or "Jetaway" transmission. The original Hydra-Matic remained in production until the mid-1960s at GM, with the licensed Rolls-Royce Automatic transmission soldiering on until 1978 on the ]. In 1964, General Motors released a new transmission, the ], a three-speed transmission which used a torque convertor. The Turbo Hydramatic was among the first to have the basic gear selections (''park'', ''reverse'', ''neutral'', ''drive'', ''low'') which became the standard gear selection used for several decades. | |||

| Depending on the model and make of the transmission, these controls can take several forms. However most include the following: | |||

| ====1965–present: increased ratio count and electronics==== | |||

| ;Park (P): This selection mechanically locks the output shaft of transmission, restricting the vehicle from moving in any direction. A ] prevents the transmission from rotating, and therefore the vehicle from moving. However, it should be noted that the vehicle's non-driven wheels are still free to rotate, and the driven wheels may still rotate individually (because of the ]). For this reason, it is recommended to use the ] (''parking brake'') because this actually locks (in most cases) the wheels and prevents them from moving. It is typical of front-wheel-drive vehicles for the parking brake to lock the rear (non-driving) wheels, so use of both the parking brake and the transmission park lock provides the greatest security against unintended movement on slopes. This also increases the life of the transmission and the park pin mechanism, because parking on an incline with the transmission in park without the parking brake engaged will cause undue stress on the parking pin, and may even prevent the pin from releasing. A hand brake should also prevent the car from moving if a worn selector accidentally drops into reverse gear while idling. | |||

| By the late 1960s, most of the fluid-coupling two-speed and four-speed transmissions had disappeared in favor of three-speed units with torque converters. Also around this time, ] was removed from the automatic transmission fluid.<ref>{{cite web|url=http://www.machinerylubrication.com/article_detail.asp?articleid=392 |title=Almost Burned |website=www.machinerylubrication.com |archive-url=https://web.archive.org/web/20070927082224/http://www.machinerylubrication.com/article_detail.asp?articleid=392 |archive-date=27 September 2007}}</ref> During the 1980s, automatic transmissions with four gear ratios became increasingly common,<ref>{{cite web |title=U.S. Patent 5370589 |url=http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO2&Sect2=HITOFF&u=%2Fnetahtml%2FPTO%2Fsearch-adv.htm&r=1&p=1&f=G&l=50&d=PTXT&S1=5370589.PN.&OS=pn%2F5370589&RS=PN%2F5370589 |website=www.patft.uspto.gov |archive-url=https://web.archive.org/web/20130514181727/http://patft.uspto.gov/netacgi/nph-Parser?Sect1=PTO2&Sect2=HITOFF&u=%2Fnetahtml%2FPTO%2Fsearch-adv.htm&r=1&p=1&f=G&l=50&d=PTXT&S1=5370589.PN.&OS=pn%2F5370589&RS=PN%2F5370589 |archive-date=14 May 2013 |url-status=dead}}</ref> and many were equipped with lock-up torque convertors in order to improve fuel economy. | |||

| ] began to be more commonly used to control the transmission, replacing mechanical control methods such as spring-loaded valves in the valve body. Most systems use ]s which are controlled by either the ], or a separate ]. This allows for more precise control of shift points, shift quality, lower shift times and manual control. | |||

| :A car should be allowed to come to a complete stop before setting the transmission into park to prevent damage. Usually, Park ('''P''') is one of only two selections in which the car's engine can be started, the other being Neutral ('''N'''). This is typically achieved via a normally open inhibitor switch (sometimes called a "neutral safety switch") wired in series with the starter motor engagement circuit, which is closed when '''P''' or '''N''' is selected, completing the circuit (when the key is turned to the start position). In many modern cars and trucks, the driver must have the foot brake applied before the transmission can be taken out of park. The Park position is omitted on buses/coaches (and some road tractors) with automatic transmission (on which a parking pawl is not practical), which must instead be placed in neutral with the air-operated parking brakes set. | |||

| The first five-speed automatic was the ], debuting in 1991 on various ] models. The first six-speed automatic was the ], which debuted in the 2002 ]. The first seven-speed automatic was the ], which debuted a year later. In 2007, the first eight-speed transmission to reach production was the ]. The first nine-speed and ten-speed transmissions were the 2013 ] and 2017 ''Toyota Direct Shift-10A'' (used in the ]) respectively. | |||

| ;Reverse ('''R'''): This engages reverse gear within the transmission, permitting the vehicle to be driven backward, and operates a switch to turn on the white backup lights for improved visibility (the switch may also activate a beeper on delivery trucks or other large vehicles to audibly warn other drivers and nearby pedestrians of the driver's reverse movement). To select reverse in most transmissions, the driver must come to a complete stop, depress the shift-lock button (or move the shift lever toward the driver in a column shifter, or move the shifter sideways along a notched channel in a console shifter) and select reverse. The driver should avoid engaging reverse while the vehicle is moving forwards, and likewise avoid engaging any forward gear while travelling backwards. On transmissions with a torque converter, doing so at very low speed (walking pace) is not harmful, but causes unnecessary wear on clutches and bands, and a sudden deceleration that not only is uncomfortable, but also uncontrollable since the brakes and the throttle contribute in the same direction. This sudden acceleration, or ], can still be felt when engaging the gear at standstill, but the driver normally suppresses this by holding the brakes. Travelling slowly in the right direction while engaging the gear minimizes the jerk further, which is actually beneficial to the wearing parts of the transmission. Electronically controlled transmissions may behave differently, as engaging a gear at speed is essentially undefined behaviour. Some modern transmissions have a safety mechanism that will resist putting the car in reverse when the vehicle is moving forward; such a mechanism may consist of a solenoid-controlled physical barrier on either side of the reverse position, electronically engaged by a switch on the ] ], so that the brake pedal needs to be depressed in order to allow the selection of reverse. Some electronic transmissions prevent or delay engagement of reverse gear altogether while the car is moving. | |||

| ===Gear selectors=== | |||

| :Some shifters with a shift button allow the driver to freely move the shifter from '''R''' to '''N''' or '''D''' without actually depressing the button. However, the driver cannot shift back to R without depressing the shift button, to prevent accidental shifting which could damage the transmission, especially at high speeds. | |||

| {{main|Gear stick #Automatic transmission}} | |||

| The gear selector is the input by which the driver selects the operating mode of an automatic transmission.<ref>{{cite book|title=Automatic transmissions and transaxles|author=Thomas W Birch|publisher=Pearson Education|place=Upper Saddle River, N.J.|year=2012|isbn=9780132622271}}</ref> Traditionally the gear selector is located between the two front seats or on the steering column, however electronic rotary dials and push-buttons have also been occasionally used since the 1980s, as well as push buttons having been used in the 1950s and 1960s by ], ], and most famously, by ]. A few automobiles employed a lever on the instrument panel, such as the 1955 Chrysler Corporation cars, and notably, the Corvair. | |||

| ====P–R–N–D–L positions==== | |||

| ;Neutral / No gear (N): This disengages all gear trains within the transmission, effectively disconnecting the transmission from the driven wheels, allowing the vehicle to coast freely under its own weight and gain momentum without the motive force from the engine. Coasting in idle down long grades (where law permits) should be avoided, though, as the transmission's lubrication pump is driven by non-idle engine RPMs. Similarly, emergency towing with an automatic transmission in neutral should be a last resort. Manufacturers understand emergency situations and list limitations of towing a vehicle in neutral (usually not to exceed 55 mph and 50 miles). This is the only other selection in which the vehicle's engine may be started. | |||

| Most cars use a "P–R–N–D–L" layout for the gear selector, which consists of the following positions:<ref>{{cite web |url=https://www.ecfr.gov/current/title-49/subtitle-B/chapter-V/part-571/subpart-B/section-571.102 |title=Standard No. 102; Transmission shift position sequence |website=Code of Federal Regulations |at=Title 49 § 571.102 |access-date=August 16, 2023}}</ref> | |||

| * '''Park''' (''P''): This position disengages the transmission from the engine (as with the ''neutral'' position), and a ] mechanically locks the output shaft of the transmission. This prevents the driven wheels from rotating to prevent the vehicle from moving. The use of the ] (''parking brake'') is also recommended when parking on slopes, since this provides greater protection from the vehicle moving. The ''park'' position is omitted on buses/coaches/tractors, which must instead be placed in ''neutral'' with the air-operated parking brakes set. Some early passenger car automatics, such as the pre-1960 ] cars and the ], did not have the ''park'' feature at all. These cars were started in ''neutral'' and required the driver to apply a parking brake when parked. The original ] from GM instead engaged a parking pawl when placed in ''reverse'' with the engine off, thus dispensing with a ''park'' position until the adoption of the Controlled Coupling Hydra-Matic in 1956.<br>The ''park'' position usually includes a lockout function (such as a button on the side of the gear selector or requiring that the brake pedal be pressed) which prevents the transmission from being accidentally shifted from ''park'' into other gear selector positions. Many cars also prevent the engine from being started when the selector is in any position other than ''park'' or ''neutral'' (often in combination with requiring the brake pedal to be pressed). | |||

| ;Drive (D): This position allows the transmission to engage the full range of available forward gear ratios, allowing the vehicle to move forward and accelerate through its range of gears. The number of gear ratios within the transmission depends on the model, but they initially ranged from three (predominant before the 1990s), to four and five speeds (losing popularity to six-speed autos). Six-speed automatic transmissions are probably the most common offering in cars and trucks from 2010 in carmakers as ], ] and ]. However, seven-speed automatics are becoming available in some high-performance production luxury cars (found in ] ] gearbox, ]), as are eight-speed autos in models from 2006 introduced by ] in ], ] and ]. From 2013 are available nine speeds transmissions produced by ] and ] ]. | |||

| * '''Reverse''' (''R''): This position engages ''reverse'' gear, so that the vehicle drives in a backwards direction.<ref>{{cite web|url=https://www.merriam-webster.com/dictionary/reverse%20gear |title=Reverse Gear |publisher=Merriam-webster.com |access-date=2018-06-24}}</ref> It also operates the reversing lights and on some vehicles can activate other functions including ]s, ]s and reversing beepers (to warn pedestrians).<br>Some modern transmissions have a mechanism that will prevent shifting into the ''reverse'' position when the vehicle is moving forward, often using a switch on the brake pedal or electronic transmission controls that monitor the vehicle speed. | |||

| * '''Neutral''' (''N''): This position disengages the transmission from the engine, allowing the vehicle to move regardless of the engine's speed. Prolonged movement of the vehicle in ''neutral'' with the engine off at significant speeds ("coasting") can damage some automatic transmissions, since the lubrication pump is often powered by the input side of the transmission and is therefore not running when the transmission is in ''neutral''. The vehicle may be started in ''neutral'' as well as ''park''. | |||

| * '''Drive''' (''D''): This position is the normal mode for driving forwards. It allows the transmission to engage the full range of available forward gear ratios. | |||

| *'''Low''' (''L''): This position provides for engine braking on steep hills. It also provides for a lower gear ratio for starting out when heavily loaded. | |||

| Some automatic transmissions, especially by ] from 1940 to 1964, used a layout with ''reverse'' as the bottom position (e.g. N–D–L–R or P–N–D–L–R).<ref>{{cite news |url=https://www.thestar.com/autos/2016/11/12/prndl-why-mess-with-it.html |title=PRNDL — why mess with it? |work=Toronto Star |first=Jim |last=Kenzie |date=November 12, 2016 |access-date=August 16, 2023}}</ref>{{failed verification |date=August 2023}} | |||

| ;Overdrive ('D', 'OD', or a boxed or the absence of an illuminated 'O/D OFF'): This mode is used in some transmissions to allow early computer-controlled transmissions to engage the automatic ]. In these transmissions, Drive (D) locks the automatic overdrive off, but is identical otherwise. OD (Overdrive) in these cars is engaged under steady speeds or low acceleration at approximately {{convert|35|-|45|mph|km/h|abbr=on}}. Under hard acceleration or below {{convert|35|-|45|mph|km/h|abbr=on}}, the transmission will automatically downshift. Other vehicles with this selector (for example light trucks) will not only disable up-shift to the overdrive gear, but keep the remaining available gears continuously engaged to the engine for use of compression braking. Drivers should verify the behaviour of this switch and consider the benefits of reduced friction brake use when city driving where speeds typically do not necessitate the overdrive gear. | |||

| ====Other positions and modes==== | |||

| Most automatic transmissions include some means of forcing a downshift (Throttle kickdown) into the lowest possible gear ratio if the throttle pedal is ]. In many older designs, kickdown is accomplished by mechanically actuating a valve inside the transmission. Most modern designs use a ]-operated valve that is triggered by a switch on the throttle linkage or by the engine control unit (ECU) in response to an abrupt increase in engine power. | |||

| ] bus]] | |||

| Many transmissions also include positions to restrict the gear selection to the lower gears and engages the ]. These positions are often labelled "L" (low gear), "S" (second gear) or the number of the highest gear used in that position (eg 3, 2 or 1). If these positions are engaged at a time when it would result in excessive engine speed, many modern transmissions disregard the selector position and remain in the higher gear. | |||

| In descending order of the highest gear available: | |||

| Mode selection allows the driver to choose between preset shifting programs. For example, Economy mode saves fuel by upshifting at lower engine speeds, while Sport mode (aka "Power" or "Performance") delays upshifting for maximum acceleration. Some transmission units also have Winter mode, where higher gear ratios are chosen to keep revs as low as possible while on slippery surfaces. The modes also change how the computer responds to throttle input. | |||

| * '''3''': Restricts the transmission to the lowest three gear ratios. In a 4-speed automatic transmission, this is often used to prevent the car shifting into the ] ratio. In some cars,{{which|date=November 2020}} the position labelled "D" performs this function, while another position labelled "OD" or a boxed "" allows all gears to be used. | |||

| * '''2''' (also labelled "S"): Restricts the transmission to the lowest two gear ratios. In some cars, it is also used to accelerate from standstill in 2nd gear instead of 1st, for situations of reduced traction (such as snow or gravel). This function is sometimes called "winter mode", labelled "W". | |||

| * '''1''' (also labelled "L"): Restricts the transmission to 1st gear only, also known as a "low gear". This is useful when a large torque is required at the wheels (for example, when accelerating up a steep incline); however use at higher speeds can run the engine at an excessive speed, risking overheating or damage. | |||

| Many modern transmissions include modes to adjust the shift logic to prefer either ] or ]. "Sport" (also called "Power" or "Performance") modes cause gear shifts to occur at higher engine speeds, allowing higher acceleration. "Economy" (also called "Eco" or "Comfort") modes cause gear shifts to occur at lower engine speeds to reduce fuel consumption. | |||

| Conventionally, automatic transmissions have selector positions that allow the driver to limit the maximum ratio that the transmission may engage. On older transmissions, this was accomplished by a mechanical lockout in the transmission valve body preventing an upshift until the lockout was disengaged; on computer-controlled transmissions, the same effect is accomplished by firmware. The transmission can still upshift and downshift automatically between the remaining ratios: for example, in the ''3'' range, a transmission could shift from first to second to third, but not into fourth or higher ratios. Some transmissions will still upshift automatically into the higher ratio if the engine reaches its maximum permissible speed in the selected range{{Citation needed|date=April 2010}}. | |||

| ====Manual controls==== | |||

| ;Third (3): This mode limits the transmission to the first three gear ratios, or sometimes locks the transmission in third gear. This can be used to climb or going down hill. Some vehicles will automatically shift up out of third gear in this mode if a certain ] (RPM) range is reached in order to prevent engine damage. This gear is also recommended while towing a trailer. | |||

| {{main|Manumatic}} | |||

| ] ]] | |||

| Since the 1990s, systems to manually request a specific gear or an upshift/downshift have become more common. These ''manumatic'' transmissions offer the driver greater control over the gear selection that the traditional modes to restrict the transmission to the lower gears. | |||

| Use of the manumatic functions are typically achieved either via paddles located beside the steering column, or "+" and "-" controls on the gear selector. Some cars offer drivers both methods to request a manual gear selection. | |||

| ;Second (2 or S): This mode limits the transmission to the first two gear ratios, or locks the transmission in second gear on ], ], and ] models. This can be used to drive in adverse conditions such as ] and ice, as well as climbing or going down hills in winter. It is usually recommended to use second gear for starting on snow and ice, and use of this position enables this with an automatic transmission. Some vehicles will automatically shift up out of second gear in this mode if a certain RPM range is reached in order to prevent engine damage. | |||

| {{clear right}} | |||

| ==Continuously variable transmission (CVT)== | |||

| :Although traditionally considered second gear, there are other names used. ] models with a three-speed automatic since the late 1980s have called this gear '''3''' while using the traditional names for ''Drive'' and ''Low''. ] has called second gear as the 'Super' range — which was first used on their 4-speed Hydramatic transmissions, although the use of this term continued until the early 1980s when GM's Turbo Hydramatic automatic transmissions were standardized by all of their divisions years after the 4-speed Hydramatic was discontinued. | |||

| {{Main|Continuously variable transmission}} | |||

| ] | |||

| A ''continuously variable transmission'' (CVT) can change seamlessly through a continuous (infinite) range of gear ratios, compared with other automatic transmissions that provide a limited number of gear ratios in fixed steps. The flexibility of a CVT with suitable control may allow the engine to operate at a constant angular velocity while the vehicle moves at varying speeds. | |||

| CVTs are used in ]s, ]s, ], ]s, ]s, and ]. | |||

| Some automatics, particularly those fitted to larger capacity or high torque engines, either when "2" is manually selected, or by engaging a winter mode, will start off in second gear instead of first, and then not shift into a higher gear until returned to "D." Also note that as with most American automatic transmissions, selecting "2" using the selection lever will not tell the transmission to be in only 2nd gear; rather, it will simply limit the transmission to 2nd gear after prolonging the duration of 1st gear through higher speeds than normal operation. The 2000–2002 Lincoln LS V8 (the five-speed automatic ''without'' manumatic capabilities, as opposed to the optional sport package w/ manu-matic 5-speed) started in 2nd gear during most starts both in winter and other seasons by selecting the "D5" transmission selection notch in the shiftgate (for fuel savings), whereas "D4" would always start in 1st gear. This is done to reduce torque multiplication when proceeding forward from a standstill in conditions where traction was limited — on snow- or ice-covered roads, for example. | |||

| The most common type of CVT uses two pulleys connected by a ] or ], however, several other designs have also been used. | |||

| ;First (1 or L ): This mode locks the transmission in first gear only. In older vehicles, it will not change to any other gear range. Some vehicles will automatically shift up out of first gear in this mode if a certain RPM range is reached in order to prevent engine damage. This, like second, can be used during the winter season, for towing, or for downhill driving to increase the engine braking effect. The "Austin ]" automatic transmission is different in this respect - This mode locks the transmission in first gear, but the gearbox has a freewheel on the overrun. Closing the throttle after accelaration results in the vehicle continuing at the same speed and only slowing down due to friction and wind resistance. During this time, the engine RPM will drop back to idle until the throttle is pressed again. What this means is that in "First", engine braking is not available and "2" is the lowest gear that should be used whilst descending hills. | |||

| {{clear right}} | |||

| ==Dual-clutch transmission (DCT)== | |||

| ], with the driver's hand on it. Manumatics and paddle shifters may control any type of automatic transmission, including the ] in the Accord.]] | |||

| {{Main|Dual-clutch transmission}} | |||

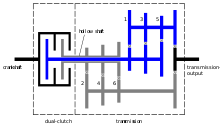

| ] | |||

| A ''dual-clutch transmission'' (DCT, sometimes referred to as a ''twin-clutch transmission'', or ''double-clutch transmission'') uses two separate ]es for odd and even ].<ref name=AMS>{{cite journal|title=Powertrain — transmissions: Shift in power to the gearbox|url=http://www.unofficialbmw.com/images/SHIFT1.pdf|journal=]|publisher=UnofficialBMW.com|date=September–October 2003|access-date=31 October 2009|url-status=live|archive-url=https://web.archive.org/web/20110717164509/http://www.unofficialbmw.com/images/SHIFT1.pdf|archive-date=17 July 2011}}</ref> The design is often similar to two separate ]s with their respective clutches contained within one housing, and working as one unit.<ref name="AEI">{{cite journal|title=Automatic-shifting dual-clutch transmissions are poised to grab share from traditional transmissions thanks to their combination of efficiency and convenience|url=http://www.dctfacts.com/documents/1-117-6-20.pdf|journal=AEI-online.org|publisher=DCTfacts.com|date=June 2009|access-date=31 October 2009|url-status=dead|archive-url=https://web.archive.org/web/20111007173150/http://www.dctfacts.com/documents/1-117-6-20.pdf|archive-date=7 October 2011}}</ref><ref name="PorschePDK_Glossary">{{cite web |title=Porsche Doppelkupplung (PDK) |url=http://www.porsche.com/microsite/technology/default.aspx?pool=uk&ShowSingleTechterm=PTPDopKuGe&Category=&Model=&SearchedString=&SelectedVariant=|publisher=Porsche.com |access-date=31 October 2009 |url-status=dead |archive-url=https://web.archive.org/web/20081205135604/http://www.porsche.com/microsite/technology/default.aspx?pool=uk&ShowSingleTechterm=PTPDopKuGe&Category=&Model=&SearchedString=&SelectedVariant=|archive-date=5 December 2008}}</ref> In most car and truck applications, the DCT functions as an automatic transmission, requiring no driver input to change gears. | |||

| The first DCT to reach production was the ''Easidrive'' automatic transmission introduced on the 1961 '']'' mid-size car. This was followed by various eastern European tractors through the 1970s (using manual operation via a single clutch pedal), then the '']'' racing car in 1985. The first DCT of the modern era was used in the 2003 ''Volkswagen Golf R32''. Since the late 2000s, DCTs have become increasingly widespread, and have supplanted hydraulic automatic transmissions in various models of cars. | |||

| ===Manual controls=== | |||

| {{clear right}} | |||

| Some transmissions have a mode in which the driver has full control of ratios change (either by moving the selector, or through the use of buttons or paddles), completely overriding the automated function of the hydraulic controller. Such control is particularly useful in cornering, to avoid unwanted upshifts or downshifts that could compromise the vehicle's balance or traction. "Manumatic" shifters, first popularized by ] in the 1990s under the ] ], have become a popular option on ]s and other performance vehicles. With the near-universal prevalence of electronically controlled transmissions, they are comparatively simple and inexpensive, requiring only software changes, and the provision of the actual manual controls for the driver. The amount of true manual control provided is highly variable: some systems will override the driver's selections under certain conditions, generally in the interest of preventing engine damage. Since these gearboxes also have a throttle kickdown switch, it is impossible to fully exploit the engine power at low to medium engine speeds{{Dubious|date=April 2010}}{{Citation needed|date=April 2010}}. | |||

| ==Automated manual transmission (AMT)== | |||

| ===Manufacturer-specific modes=== | |||

| {{Main|Automated manual transmission}} | |||

| As well as the above modes there are other modes, dependent on the manufacturer and model. Some examples include: | |||

| ''Automated manual transmission (AMT)'', sometimes referred to as a ''clutchless manual'', is a type of multi-speed ] ] that is closely based on the mechanical design of a conventional ], and automates either the clutch system, the gear shifting, or both simultaneously, requiring partial, or no driver input or involvement.<ref name="NAP"/><ref>{{cite journal |title=Research on Accurate Engagement Control of Electrohydraulic Clutch Actuator |url=https://www.sae.org/publications/technical-papers/content/2005-01-1787/ |website=www.sae.org |series=SAE Technical Paper Series |access-date=26 July 2020 |language=en |date=11 April 2005|doi=10.4271/2005-01-1787 |last1=Yulong |first1=Lei |last2=Hua |first2=Tian |volume=1}}</ref><ref>{{cite web |title=Transmission Actuation |url=https://www.fte-automotive.com/fileadmin/user_upload/Valeo_Getriebe_EN_web.pdf |website=www.fte-automotive.com |access-date=26 July 2020 |archive-date=3 November 2022 |archive-url=https://web.archive.org/web/20221103071423/https://www.fte-automotive.com/fileadmin/user_upload/Valeo_Getriebe_EN_web.pdf |url-status=dead}}</ref><ref>{{Cite web|url=https://www.repairsmith.com/i/blog/manual-vs-automatic-transmission-shift-know-about/|title=Manual vs Automatic Transmission: A Shift to Know About {{pipe}} RepairSmith Blog|date=May 6, 2020}}</ref> | |||

| Earlier versions of these transmissions that are ] in operation, such as '']'', control only the ] system ] — and use different forms of actuation (usually via an ] or ]) to automate the clutch, but still require the driver's input and full control to manually actuate gear changes by hand. Modern versions of these systems that are fully automatic in operation, such as '']'' and '']'', require no driver input over gear changes or clutch operation. Semi-automatic versions require only partial driver input (i.e., the driver must change gears manually), while fully automatic versions require no manual driver input, whatsoever (] or ] operates both the clutch system and gear shifts automatically). | |||

| ;D5: In ]s and ]s equipped with five-speed automatic transmissions, this mode is used commonly for highway use (as stated in the manual), and uses all five forward gear ratios. | |||

| ;D4: This mode is also found in Honda and Acura four or five-speed automatics, and only uses the first four gear ratios. According to the manual, it is used for stop-and-go traffic, such as city driving. | |||

| ;D3 or 3: This mode is found in Honda, Acura, Volkswagen and Pontiac four-speed automatics and only uses the first three gear ratios. According to the manual, it is used for stop-and-go traffic, such as city driving. | |||

| ;D2 and D1: These modes are found on older Ford transmissions (C6, etc.). In D1, all three gears are used, whereas in D2 the car starts in second gear and upshifts to third. | |||

| ;S or Sport: This is commonly described as Sport mode. It operates in an identical manner as "D" mode, except that the upshifts change much higher up the engine's rev range. This has the effect on maximising all the available engine output, and therefore enhances the performance of the vehicle, particularly during acceleration. This mode will also downchange much higher up the rev range compared to "D" mode, maximising the effects of ]. This mode will have a detrimental effect on fuel economy. Hyundai has a Norm/Power switch next to the gearshift for this purpose on the ''Tiburon''. | |||

| Modern automated manual transmissions (AMT) have their roots and origins in older ] transmissions that began to appear on mass-production automobiles in the early 1930s and 1940s, prior to the introduction of hydraulic automatic transmissions. These systems were designed to reduce the amount of clutch or gear shifter usage required by the driver.<ref>{{Cite web|url=https://www.caranddriver.com/research/a31862769/how-does-an-automatic-transmission-work/|title=How Does an Automatic Transmission Work?|first=Hearst Autos|last=Research|date=April 13, 2020|website=Car and Driver}}</ref> These devices were intended to reduce the difficulty of operating conventional ] ("crash gearboxes") that were commonly used at the time, especially in stop-start driving. An early example of this transmission was introduced with the ] in 1942, called ''Drive-Master''. This unit was an early ], based on the design of a conventional manual transmission, which used a ]-controlled ]-operated clutch system, with three different gear shifting modes, at the touch of a button; manual shifting and manual clutch operation (fully manual), manual shifting with automated clutch operation (semi-automatic), and automatic shifting with automatic clutch operation (fully automatic).<ref>{{Cite web |url=https://auto.howstuffworks.com/1941-1947-hudson3.htm |title=1942 Hudson {{pipe}} HowStuffWorks |access-date=2020-11-25 |archive-date=2020-08-12 |archive-url=https://web.archive.org/web/20200812072455/https://auto.howstuffworks.com/1941-1947-hudson3.htm |url-status=dead}}</ref><ref>{{cite web |url=http://hudsonterraplane.com/tech/other/DrivemasterServiceInformation.pdf |title=Hudson Drive-Master Service Information |publisher=Hudson Motor Car Company |location=Detroit, Michigan |access-date=9 July 2021 |url-status=live|archive-url=https://web.archive.org/web/20160319034651/http://www.hudsonterraplane.com/tech/other/DrivemasterServiceInformation.pdf |archive-date=2016-03-19}}</ref><ref>{{Cite web |url=https://auto.howstuffworks.com/1950-hudson-commodore.htm |title=1950 Hudson Commodore {{pipe}} HowStuffWorks |access-date=2020-11-25 |archive-date=2020-10-23 |archive-url=https://web.archive.org/web/20201023002530/https://auto.howstuffworks.com/1950-hudson-commodore.htm |url-status=dead}}</ref> Another early example of this transmission system was introduced in the 1955 ], which used a 4-speed ''BVH'' transmission. This semi-automatic transmission used an automated clutch, which was ]. Gear selection also used ], however, the gear ratio needs to be manually selected by the driver. This system was nicknamed ''Citro-Matic'' in the U.S. | |||

| Some early GMs equipped with HYDRA-MATIC transmissions used (S) to indicate Second gear, being the same as the 2 position on a Chrysler, shifting between only first and second gears. This would have been recommended for use on steep grades, or slippery roads like dirt, or ice, and limited to speeds under 40 mph. (L) was used in some early GMs to indicate (L)ow gear, being the same as the 2 position on a Chrysler, locking the transmission into first gear. This would have been recommended for use on steep grades, or slippery roads like dirt, or ice, and limited to speeds under 15 mph. | |||

| The first modern AMTs were introduced by ] and ] in 1997, with their ''SMG'' and ''F1'' transmissions, respectively.<ref>{{Cite web|url=https://magazine.ferrari.com/en/cars/2020/04/24/news/the-ferrari-automated-gearbox-from-f1-to-ferrari-roma-79244/|title=Gearing Up|website=magazine.ferrari.com}}</ref><ref>{{Cite web|url=https://europe.autonews.com/article/19970804/ANE/708040768/ferrari-launches-f1-style-gearbox-on-f355|title=FERRARI LAUNCHES F1-STYLE GEARBOX ON F355|date=August 4, 1997|website=Automotive News Europe}}</ref><ref>{{Cite web|url=https://europe.autonews.com/article/19970609/ANE/706090799/magneti-marelli-transmission-from-f1|title=MAGNETI MARELLI: TRANSMISSION FROM F1|date=June 9, 1997|website=Automotive News Europe}}</ref> Both systems used ]s and ], and a designated ] (TCU) for the clutch and shifting, plus steering wheel-mounted paddle shifters, if the driver wanted to change gear manually. | |||