| Revision as of 13:32, 20 October 2016 editMais oui! (talk | contribs)Autopatrolled, Extended confirmed users, Pending changes reviewers, Rollbackers111,268 edits added Category:Articles containing video clips using HotCat← Previous edit | Latest revision as of 20:28, 10 January 2025 edit undoSauer202 (talk | contribs)Extended confirmed users20,340 edits →See also | ||

| (103 intermediate revisions by 61 users not shown) | |||

| Line 1: | Line 1: | ||

| {{Short description|Self-replicating 3D printer initiative}} | |||

| ] | |||

| {{Use dmy dates|date=April 2022}} | |||

| ] | |||

| ] | |||

| ] talking about the RepRap Project at ] 2007]] | |||

| ] | |||

| The '''RepRap project''' started as a ] initiative to develop a ] that can print most of its own components and be a low-cost 3D printer, but it is now made up of hundreds of collaborators world wide.<ref name="Jones, R. 2011">{{cite journal | last1 = Jones | first1 = R. | last2 = Haufe | first2 = P. | last3 = Sells | first3 = E. | last4 = Iravani | first4 = P. | last5 = Olliver | first5 = V. | last6 = Palmer | first6 = C. | last7 = Bowyer | first7 = A. | year = 2011 | title = Reprap-- the replicating rapid prototyper | url = | journal = Robotica | volume = 29 | issue = 1| pages = 177–191 | doi=10.1017/s026357471000069x}}</ref> RepRap is short for ''replicating rapid prototyper''. | |||

| '''RepRap''' (a contraction of ''replicating rapid prototyper'') is a project to develop low-cost ]s that can print most of their own components. As ]s, all of the designs produced by the project are released under a ], the ].<ref name="license "/> | |||

| Due to the ability of |

Due to the ability of these machines to make some of their own parts, authors envisioned the possibility of cheap RepRap units, enabling the manufacture of complex products without the need for extensive industrial infrastructure.<ref name="Pearce "/><ref name="buildosh "/><ref name="osl "/> They intended for the RepRap to demonstrate ] in this process as well as for it to increase in number exponentially.<ref name="Jones, R. 2011" /><ref name="Sells "/> A preliminary study claimed that using RepRaps to print common products results in economic savings.<ref name="Wittbrodt "/> | ||

| The RepRap project started in ] in 2005 as a ] initiative, but it is now made up of hundreds of collaborators worldwide.<ref name="Jones, R. 2011 "/> | |||

| == History == | == History == | ||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | ] | ||

| RepRap was founded in 2005 by |

RepRap was founded in 2005 by ], a Senior Lecturer in ] at the ] in England. Funding was obtained from the ]. | ||

| On 13 September 2006, the RepRap 0.2 prototype |

On 13 September 2006, the RepRap 0.2 prototype printed the first part identical to its own, which was then substituted for the original part created by a commercial 3D printer. On 9 February 2008, RepRap 1.0 "Darwin" made at least one instance of over half its rapid-prototyped parts. On 14 April 2008, RepRap made an end-user item: a clamp to hold an ] to the dashboard of a ] car. By September that year, at least 100 copies had been produced in various countries.<ref name="Power "/> On 29 May 2008, Darwin achieved self replication by making a complete copy of all its rapid-prototyped parts<ref name="Olliver "/> (which represent 48% of all the parts, excluding fasteners). A couple hours later the "child" machine had made its first part: a timing-belt tensioner. | ||

| In April 2009 electronic circuit boards were produced automatically with a RepRap, using an automated control system and a swappable head system capable of printing both plastic and conductive solder. On 2 October 2009, the second generation design, called |

In April 2009, electronic circuit boards were produced automatically with a RepRap, using an automated control system and a swappable head system capable of printing both plastic and conductive solder. On 2 October 2009, the second generation design, called Mendel, printed its first part. Mendel's shape resembles a ] rather than a cube. Mendel was completed in October 2009. On 27 January 2010, the ] announced the "Kartik M. Gada Humanitarian Innovation Prize" for the design and construction of an improved RepRap.<ref name="Gada Prize "/> | ||

| On 31 August 2010, the third generation design was named Huxley. It was a miniature of Mendel, with 30% of the original print volume. Within two years, RepRap and ] building and use were widespread in the technology, gadget and engineering communities.<ref name="Ingeniøren "/> | |||

| Within two years, RepRap and ] building and usage were widespread within the tech, gadget, and engineering communities.<ref>{{cite web | title=Ingeniøren | url=http://ing.dk/tema/3d-print| publisher= Ingeniøren media | date=2012-09-26 |accessdate=2012-09-26 }}</ref> In 2012, the first successful Delta design, Rostock, had a radically different design. The latest iterations used ]s, wires (typically Dyneema or Spectra fishing lines) instead of belts, and so forth, which also represented some of the latest trends in RepRaps.{{cn|date=April 2016}} | |||

| In 2012, the first successful Delta design, Rostock, had a radically different design. The latest iterations used ]s, wires (typically Dyneema or Spectra fishing lines) instead of belts, and so forth, which also represented some of the latest trends in RepRaps.{{citation needed|date=April 2016}} | |||

| In early January 2016 RepRapPro (short for "RepRap Professional", and one commercial arm of the RepRap project in the UK) announced that they are to cease trading on 15 January 2016. The reason given was congestion of the market for low-cost 3D printers and the inability to expand in that market. RepRapPro China continues to operate.<ref>{{cite web |url=http://www.reprappro.com |title=RepRap Professional Ltd. is now closed. |date=6 January 2016}}</ref> | |||

| In early January 2016, RepRapPro (short for "RepRap Professional", and one commercial arm of the RepRap project in the UK) announced that it would cease trading on 15 January 2016. The reason given was congestion of the market for low-cost 3D printers and the inability to expand in that market. RepRapPro China continues to operate.<ref name="reprappro "/> | |||

| == Hardware == | == Hardware == | ||

| As the project was designed by |

As the project was designed by Bowyer to encourage evolution, many variations have been created.<ref name="RepRap Family Tree "/><ref name="Chulilla "/> As an ] project, designers are free to make modifications and substitutions, but they must allow any of their potential improvements to be reused by others. | ||

| There are many RepRap printer designs including: | |||

| * ] | |||

| === Major revisions === | |||

| * ] | |||

| ]) being printed using FDM on a RepRapPro Fisher, a delta-style printer.]] | |||

| * RepRap Fisher | |||

| One of the more popular RepRap variants from 2013 and beyond is the ] delta-style RepRap.<ref>http://reprap.org/Rostock</ref> | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * RepRap Darwin | |||

| * RepRap Mendel | |||

| == Software == | == Software == | ||

| ] 2007]] | |||

| RepRap |

RepRap was conceived as a complete replication system rather than simply a piece of hardware. To this end the system includes ] (CAD) in the form of a ] system and ] (CAM) software and drivers that convert RepRap users' designs into a set of instructions to the RepRap to create physical objects. | ||

| Initially two |

Initially, two CAM tool chains were developed for RepRap. The first, called "RepRap Host", was written in ] by lead RepRap developer Adrian Bowyer. The second, "Skeinforge",<ref name="Skeinforge "/> was written by Enrique Perez. Both are complete systems for translating 3D computer models into ], the machine language that commands the printer. | ||

| Later, other programs like ] |

Later, other programs like ] and ] were created. Recently, the Franklin firmware was created to allow RepRap printers to be used for other purposes such as milling and fluid handling.<ref name="Wijnen "/> | ||

| </ref> | |||

| The closed source ]<ref>http://www.kisslicer.com/</ref> and ]<ref>http://www.repetier.com/documentation/repetier-host/</ref> are also used. | |||

| Free and open-source 3-D modeling programs like ], ], and ] are preferred |

Free and open-source 3-D modeling programs like ], ], and ] are preferred in the RepRap community, but almost any CAD or 3D modeling program can be used with the RepRap, as long as it can produce ] files (Slic3r also supports ] and ] files). Thus, content creators make use of any tools they are familiar with, whether they are commercial CAD programs, such as ] and ], ], ], or ] along with the ]. | ||

| == Replication materials == | == Replication materials == | ||

| ]) being printed using ] on a RepRap Fisher, a delta-style printer.]] | |||

| RepRaps print objects from ], ] (PLA), ] (possibly not all extruders |

RepRaps print objects from ], ] (PLA), ] (possibly not all extruders can), ], ] and similar ]s. | ||

| The mechanical properties of RepRap-printed PLA and ABS have been tested and are equivalent to the ] of parts made by proprietary printers.<ref name="Tymrak "/> | |||

| Polylactic acid (PLA) has the engineering advantages of high stiffness, minimal warping, and an attractive translucent colour. It is also biodegradable and plant-derived. | |||

| Unlike with most commercial machines, RepRap users are encouraged to experiment with materials and methods, and to publish their results. Methods for printing novel materials (such as ceramics) have been developed this way. In addition, several ] have been designed and fabricated to convert waste plastic, such as shampoo containers and milk jugs, into inexpensive RepRap filament.<ref name="RPJ "/> There is some evidence that using this approach of distributed recycling is better for the environment<ref name="Kreiger "/><ref name="voxelfab "/><ref name="Kreiger-2 "/> and can be useful for creating "] filament".<ref name="Feeley "/> | |||

| The mechanical properties of RepRap printed PLA and ABS have been tested and have been shown to be equivalent to the ] of proprietary printers.<ref>B.M. Tymrak, M. Kreiger, ] "Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions" ''Materials & Design'', 58, pp. 242-246 (2014). doi 10.1016/j.matdes.2014.02.038. </ref> | |||

| In addition, 3D printing products at the point of consumption has also been shown to be better for the environment.<ref name="Kreiger-3 "/> | |||

| Unlike in most commercial machines, RepRap users are encouraged to experiment with printing new materials and methods, and to publish their results. Methods for printing novel materials (such as ceramics) have been developed this way. In addition, several ] have been designed and fabricated to convert waste plastic, such as shampoo containers and milk jugs, into inexpensive RepRap filament.<ref name="RPJ">{{cite journal | last1 = Baechler | first1 = Christian | last2 = DeVuono | first2 = Matthew | last3 = Pearce | first3 = Joshua M. | year = | title = Distributed Recycling of Waste Polymer into RepRap Feedstock | url = http://www.academia.edu/2643418/Distributed_Recycling_of_Waste_Polymer_into_RepRap_Feedstock | journal = Rapid Prototyping Journal | volume = 19 | issue = 2| pages = 118–125 | doi=10.1108/13552541311302978}}</ref> There is some evidence that using this approach of distributed recycling is better for the environment <ref>Kreiger, M., Anzalone, G. C., Mulder, M. L., Glover, A., & Pearce, J. M. (2013). Distributed Recycling of Post-Consumer Plastic Waste in Rural Areas. MRS Online Proceedings Library, 1492, mrsf12-1492. </ref><ref> – VoxelFab, 2013.</ref><ref>M. Kreiger, G. C. Anzalone, M. L. Mulder, A. Glover and J. M Pearce (2013). Distributed Recycling of Post-Consumer Plastic Waste in Rural Areas. MRS Online Proceedings Library, 1492, doi:10.1557/opl.2013.258. </ref> and be useful for creating "] filament".<ref>{{cite journal | last1 = Feeley | first1 = S. R. | last2 = Wijnen | first2 = B. | last3 = Pearce | first3 = J. M. | year = 2014 | title = Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament | url = https://www.academia.edu/8406439/Evaluation_of_Potential_Fair_Trade_Standards_for_an_Ethical_3-D_Printing_Filament | journal = Journal of Sustainable Development | volume = 7 | issue = 5| pages = 1–12 | doi = 10.5539/jsd.v7n5p1 }}</ref> | |||

| The RepRap project has identified ] (PVA) as a potentially suitable support material to complement its printing process, although massive overhangs can be made by extruding thin layers of the primary printing media as support (these are mechanically removed afterwards). | |||

| In addition, 3D printing products themselves at the point of consumption by the consumer has also been shown to be better for the environment.<ref>M. Kreiger and J.M. Pearce. (2013). , ''ACS Sustainable Chemistry & Engineering'''''1''' (12), (2013) pp. 1511–1519. | |||

| DOI: 10.1021/sc400093k 10.1021/sc400093k </ref> | |||

| The RepRap project has identified ] (PVA) as a potentially suitable support material to complement its printing process, although massive overhangs can be made with using thin layers of the primary printing media as support, which are mechanically removed afterwards. | |||

| Printing electronics is a major goal of the RepRap project so that it can print its own circuit boards. Several methods have been proposed: | Printing electronics is a major goal of the RepRap project so that it can print its own circuit boards. Several methods have been proposed: | ||

| * ] or ]: low-melting point metal alloys to incorporate electrical circuits into the part as it is being formed. | * ] or ]: low-melting point metal alloys to incorporate electrical circuits into the part as it is being formed. | ||

| * Silver/carbon-filled polymers: commonly used |

* Silver/carbon-filled polymers: commonly used to repair circuit boards and are being considered for use for electrically conductive traces.<ref name="plosone_Leight_Bradley "/> | ||

| * Direct extrusion of solder<ref |

* Direct extrusion of solder<ref name="first-reprapped-circuit "/> | ||

| * Conductive wires: can be laid into a part from a spool during the printing process | * Conductive wires: can be laid into a part from a spool during the printing process | ||

| Using a ] welder as a print head a RepRap ] stage can be used to print metals like ].<ref |

Using a ] welder as a print head a RepRap ] stage can be used to print metals like ].<ref name="nytimes "/><ref name="Anzalone "/> | ||

| doi: 10.1109/ACCESS.2013.2293018 </ref> | |||

| The RepRap concept can also be applied to a milling machine<ref name="Kostakis "/> and to ].<ref name="Laureto "/> | |||

| The RepRap concept can also be applied to a milling machine<ref>Kostakis, V., & Papachristou, M. (2013). Commons-based peer production and digital fabrication: The case of a RepRap-based, Lego-built 3D printing-milling machine. Telematics and Informatics.</ref> and to ]. <ref>http://www.appropedia.org/Open-source_laser_system_for_polymeric_welding </ref><ref>John J. Laureto, Serguei V. Dessiatoun, Michael M. Ohadi and Joshua M. Pearce. . ''Machines'' 2016, '''4'''(3), 14; doi: 10.3390/machines4030014 </ref> | |||

| == Construction |

== Construction == | ||

| ]]] | |||

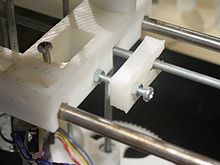

| Although the aim of the project is for RepRap to be able to autonomously construct many of its own mechanical components |

Although the aim of the project is for RepRap to be able to autonomously construct many of its own mechanical components soon using fairly low-level resources, several components such as sensors, stepper motors and ]s cannot yet be made using the RepRap's 3D printing technology and so have to be produced independently. The plan is to approach 100% replication over a series of versions. For example, from the onset of the project, the RepRap team has explored a variety of approaches to integrating electrically-conductive media into the product. This would allow inclusion of ], ]s, and possibly ] in RepRapped products. Variations in the nature of the extruded, electrically-conductive media could produce electrical components with different functions from pure conductive traces, similar to the 1940s sprayed-circuit process Electronic Circuit Making Equipment (ECME), by ]. A related approach is ]. Another non-replicable component is the threaded rods for linear motions. A current research area is in using replicated ]s to replace them.<ref name="New Scientist "/> | ||

| == Project members == | == Project members == | ||

| The "Core team" of the project<ref |

The "Core team" of the project<ref name="Core Team "/> has included: | ||

| * |

* Adrian Bowyer, Former Senior Lecturer, Mechanical Engineering Department, ] | ||

| * Ed Sells, University of Bath PhD "3D Printing: Towards a Self-Replicating Rapid Prototyping Machine"<ref name="Sells-2 "/> | |||

| * Vik Olliver, the first RepRap volunteer, the first to suggest using PLA as a printing material<ref name="Olliver-2 "/> | |||

| * ] (deceased 2011), creator of ], Illinois | * ] (deceased 2011), creator of ], Illinois | ||

| == Goals == | == Goals == | ||

| ] | |||

| The stated goal of the RepRap project is to produce a pure self-replicating device not for its own sake, but rather to put in the hands of individuals anywhere on the planet, for a minimal outlay of capital, a ] system that would enable the individual to manufacture many of the artifacts used in everyday life.<ref name="Jones, R. 2011"/> From a theoretical viewpoint, the project |

The stated goal of the RepRap project is to produce a pure self-replicating device not for its own sake, but rather to put in the hands of individuals anywhere on the planet, for a minimal outlay of capital, a ] system that would enable the individual to manufacture many of the artifacts used in everyday life.<ref name="Jones, R. 2011 "/> From a theoretical viewpoint, the project aims to prove the hypothesis that "] and direct writing technologies are sufficiently versatile to allow them to be used to make a ]".<ref name="AMPS-Project "/> | ||

| ==Education |

== Education == | ||

| RepRap technology has great potential in educational applications, according to some scholars.<ref>Chelsea Schelly, Gerald Anzalone, Bas Wijnen, Joshua M. Pearce (2015). .''Journal of Visual Languages & Computing.'' 2015; 28226–237. </ref><ref>Grujović, N., Radović, M., Kanjevac, V., Borota, J., Grujović, G., & Divac, D. (2011, September). 3D printing technology in education environment. ''In 34th International Conference on Production Engineering'' (pp. 29-30).</ref><ref>Mercuri, R., & Meredith, K. (2014, March). An educational venture into 3D Printing. In Integrated STEM Education Conference (ISEC), 2014 IEEE (pp. 1-6). IEEE.</ref> RepRaps have already been used for an educational mobile robotics platform.<ref>Gonzalez-Gomez, J., Valero-Gomez, A., Prieto-Moreno, A., & Abderrahim, M. (2012). A new open source 3d-printable mobile robotic platform for education. In ''Advances in autonomous mini robots'' (pp. 49-62). Springer Berlin Heidelberg.</ref> Some authors have claimed that RepRaps offer an unprecedented "revolution" in ] education.<ref>J. Irwin, J.M. Pearce, D. Opplinger, and G. Anzalone. , ''121st ASEE Annual Conference and Exposition, Indianapolis, IN''. Paper ID #8696 (2014).</ref> The evidence for such claims comes from both the low cost ability for ] in the classroom by students, but also the fabrication of low-cost high-quality scientific equipment from ] designs forming ].<ref name="buildosh" /><ref name="osl" /> | |||

| RepRap technology has great potential in educational applications, according to some scholars.<ref name="Schelly "/><ref name="Grujović "/><ref name="Mercuri "/> RepRaps have already been used for an educational mobile robotics platform.<ref name="Gonzalez-Gomez "/> Some authors have claimed that RepRaps offer an unprecedented "revolution" in ] education.<ref name="Irwin "/> The evidence comes from both the low cost of ] by students, and the fabrication of low-cost high-quality scientific equipment from ] designs forming ].<ref name="buildosh" /><ref name="osl" /> | |||

| == See also == | == See also == | ||

| {{Portal|Free software|Electronics}} | {{Portal|Free and open-source software|Electronics}} | ||

| * ] | |||

| * ] | |||

| {{colbegin}} | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | * ] | ||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | * ] | ||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | |||

| * ] | * ] | ||

| * ] | * ] | ||

| * ] | |||

| {{colend}} | |||

| * ] (2020), a CoreXY printer described as a resurgence of the RepRap project | |||

| == Notes == | == Notes == | ||

| {{refs|refs= | |||

| {{Reflist|colwidth=30em}} | |||

| <ref name="license">{{Cite web | url=http://reprap.org/RepRapGPLLicence | title=RepRapGPLLicence - RepRap}}</ref> | |||

| <ref name="Pearce">{{cite journal|doi=10.5539/jsd.v3n4p17|title=3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development|year=2010|last1=Pearce|first1=Joshua M.|last2=Morris Blair|first2=Christine|last3=Laciak|first3=Kristen J.|last4=Andrews|first4=Rob|last5=Nosrat|first5=Amir|last6=Zelenika-Zovko|first6=Ivana|journal=Journal of Sustainable Development|volume=3|issue=4|doi-access=free}}</ref> | |||

| <ref name="buildosh">{{cite journal | last1 = Pearce | first1 = Joshua M | year = 2012 | title = Building Research Equipment with Free, Open-Source Hardware | journal = Science | volume = 337 | issue = 6100| pages = 1303–1304 | doi=10.1126/science.1228183 | pmid=22984059| bibcode = 2012Sci...337.1303P | s2cid = 44722829 }}</ref> | |||

| <ref name="osl">J.M. Pearce, ''Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs'', Elsevier, 2014.</ref> | |||

| <ref name="Jones, R. 2011">{{cite journal | last1 = Jones | first1 = R. | last2 = Haufe | first2 = P. | last3 = Sells | first3 = E. | last4 = Iravani | first4 = P. | last5 = Olliver | first5 = V. | last6 = Palmer | first6 = C. | last7 = Bowyer | first7 = A. | year = 2011 | title = Reprap-- the replicating rapid prototyper | journal = Robotica | volume = 29 | issue = 1| pages = 177–191 | doi=10.1017/s026357471000069x| doi-access = free }}</ref> | |||

| <ref name="Sells">Sells, E., Smith, Z., Bailard, S., Bowyer, A., & Olliver, V. (2009). Reprap: the replicating rapid prototyper: maximizing customizability by breeding the means of production. Handbook of Research in Mass Customization and Personalization.</ref> | |||

| <ref name="Wittbrodt">{{cite journal | last1 = Wittbrodt | first1 = B.T. | last2 = Glover | first2 = A.G. | last3 = Laureto | first3 = J. | last4 = Anzalone | first4 = G.C. | last5 = Oppliger | first5 = D. | last6 = Irwin | first6 = J.L. | last7 = Pearce | first7 = J.M. | year = 2013 | title = Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers | url =https://hal.archives-ouvertes.fr/hal-02119705/file/Open-Source_Colorimeter.pdf| journal = Mechatronics | volume = 23 | issue = 6| pages = 713–726 | doi = 10.1016/j.mechatronics.2013.06.002 | s2cid = 1766321 }} http://digitalcommons.mtu.edu/cgi/viewcontent.cgi?article=1048&context=materials_fp</ref> | |||

| <ref name="Power">{{cite web|author=Matthew Power |url=http://www.seedmagazine.com/news/2008/09/mechanical_generation.php |archive-url=https://web.archive.org/web/20080925172835/http://www.seedmagazine.com/news/2008/09/mechanical_generation.php |url-status=unfit |archive-date=2008-09-25 |title=Mechanical Generation § |publisher=Seedmagazine |date=2008-09-23 |access-date=2010-06-04 }}</ref> | |||

| <ref name="Olliver">{{Cite tweet |author=Vik Olliver |user=VikOlliver |number=1398041308095209472 |title=Tomorrow is RepRap Day. On that day in 2008 a 3D printer first achieved self-replication. I may have assisted it slightly.}}</ref> | |||

| <ref name="Gada Prize">{{cite web|title=Gada Prizes|url=http://humanityplus.org/projects/gadaprize/|publisher=humanity+|access-date=25 April 2011|archive-date=29 July 2012|archive-url=https://web.archive.org/web/20120729122052/http://humanityplus.org/projects/gadaprize/|url-status=dead}}</ref> | |||

| <ref name="Ingeniøren">{{cite web | title=Ingeniøren | url=http://ing.dk/tema/3d-print | publisher=Ingeniøren media | date=2012-09-26 | access-date=2012-09-26 | archive-date=15 October 2012 | archive-url=https://web.archive.org/web/20121015224526/http://ing.dk/tema/3d-print | url-status=dead }}</ref> | |||

| <ref name="reprappro">{{cite web |url=http://www.reprappro.com |title=RepRap Professional Ltd. is now closed. |date=6 January 2016}}</ref> | |||

| <ref name="RepRap Family Tree"></ref> | |||

| <ref name="Chulilla">{{cite journal | last1 = Chulilla | first1 = J. L. | year = 2011 | title = The Cambrian Explosion of Popular 3D Printing | journal = International Journal of Interactive Multimedia and Artificial Intelligence | volume = 1 | page = 4 }}</ref> | |||

| <ref name="Skeinforge"></ref> | |||

| <ref name="Wijnen">{{cite journal|doi=10.5334/jors.78|title=Free and Open-source Control Software for 3-D Motion and Processing|journal=Journal of Open Research Software|year=2016|volume=4|doi-access=free|last1=Wijnen |first1=Bas |last2=Anzalone |first2=Gerald C. |last3=Haselhuhn |first3=Amberlee S. |last4=Sanders |first4=P. G. |last5=Pearce |first5=Joshua M. |page=2 }} | |||

| </ref> | |||

| <ref name="Tymrak">{{cite journal|doi=10.1016/j.matdes.2014.02.038|title=Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions|year=2014|last1=Tymrak|first1=B.M.|last2=Kreiger|first2=M.|last3=Pearce|first3=J.M.|journal=Materials & Design|volume=58|pages=242–246|s2cid=15552570 |url=https://digitalcommons.mtu.edu/materials_fp/49}}</ref> | |||

| <ref name="RPJ">{{cite journal | last1 = Baechler | first1 = Christian | last2 = DeVuono | first2 = Matthew | last3 = Pearce | first3 = Joshua M. | year = 2013| title = Distributed Recycling of Waste Polymer into RepRap Feedstock | url = https://www.academia.edu/2643418 | journal = Rapid Prototyping Journal | volume = 19 | issue = 2| pages = 118–125 | doi=10.1108/13552541311302978| s2cid = 15980607 }}</ref> | |||

| <ref name="Kreiger">Kreiger, M., Anzalone, G. C., Mulder, M. L., Glover, A., & Pearce, J. M. (2013). Distributed Recycling of Post-Consumer Plastic Waste in Rural Areas. MRS Online Proceedings Library, 1492, mrsf12-1492. </ref> | |||

| <ref name="voxelfab"> {{webarchive|url=https://web.archive.org/web/20140318062517/http://voxelfab.com/blog/2013/03/the-importance-of-the-lyman-extruder-filamaker-recyclebot-and-filabot-to-3d-printing/ |date=2014-03-18 }} – VoxelFab, 2013.</ref> | |||

| <ref name="Kreiger-2">M. Kreiger, G. C. Anzalone, M. L. Mulder, A. Glover and J. M Pearce (2013). Distributed Recycling of Post-Consumer Plastic Waste in Rural Areas. MRS Online Proceedings Library, 1492, doi:10.1557/opl.2013.258. </ref> | |||

| <ref name="Feeley">{{cite journal | last1 = Feeley | first1 = S. R. | last2 = Wijnen | first2 = B. | last3 = Pearce | first3 = J. M. | year = 2014 | title = Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament | journal = Journal of Sustainable Development | volume = 7 | issue = 5| pages = 1–12 | doi = 10.5539/jsd.v7n5p1 | doi-access = free }}</ref> | |||

| <ref name="Kreiger-3">{{cite journal|doi=10.1021/sc400093k|title=Environmental Life Cycle Analysis of Distributed Three-Dimensional Printing and Conventional Manufacturing of Polymer Products|year=2013|last1=Kreiger|first1=Megan|last2=Pearce|first2=Joshua M.|journal=ACS Sustainable Chemistry & Engineering|volume=1|issue=12|pages=1511–1519}}</ref> | |||

| <ref name="plosone_Leight_Bradley">Simon J. Leigh, Robert J. Bradley, Christopher P. Purssell, Duncan R. Billson, David A. Hutchins </ref> | |||

| <ref name="first-reprapped-circuit"> visited 2/26/2014</ref> | |||

| <ref name="nytimes"> - The New York Times</ref> | |||

| <ref name="Anzalone">{{cite journal|doi=10.1109/ACCESS.2013.2293018|title=A Low-Cost Open-Source Metal 3-D Printer|year=2013|last1=Anzalone|first1=Gerald C.|last2=Chenlong Zhang|last3=Wijnen|first3=Bas|last4=Sanders|first4=Paul G.|last5=Pearce|first5=Joshua M.|journal=IEEE Access|volume=1|pages=803–810|doi-access=free|bibcode=2013IEEEA...1..803A }}</ref> | |||

| <ref name="Kostakis">Kostakis, V., & Papachristou, M. (2013). Commons-based peer production and digital fabrication: The case of a RepRap-based, Lego-built 3D printing-milling machine. Telematics and Informatics.</ref> | |||

| <ref name="Laureto">{{cite journal|doi=10.3390/machines4030014|title=Open Source Laser Polymer Welding System: Design and Characterization of Linear Low-Density Polyethylene Multilayer Welds|year=2016|last1=Laureto|first1=John|last2=Dessiatoun|first2=Serguei|last3=Ohadi|first3=Michael|last4=Pearce|first4=Joshua|journal=Machines|volume=4|issue=3|pages=14|doi-access=free}}</ref> | |||

| <ref name="New Scientist">{{cite journal | journal = New Scientist | date = 29 May 2010 | title = I, replicator }}</ref> | |||

| <ref name="Core Team"> {{webarchive|url=https://web.archive.org/web/20130406090137/http://reprap.org/RepRapWiki%3AThe_Core_Team |date=2013-04-06 }}, reprap.org/wiki</ref> | |||

| <ref name="Sells-2">{{cite web | url=https://3dprintingindustry.com/news/interview-ed-sells-reprap-opened-multi-billion-dollar-industry-now-known-3d-printing-133978/ | title=Interview: Ed Sells, RepRap 'opened up a multi-billion dollar industry now known as 3D printing' | date=31 May 2018 |first1=Michael |last1=Petch |website=3D Printing Industry | archive-url=https://web.archive.org/web/20200728111527/https://3dprintingindustry.com/news/interview-ed-sells-reprap-opened-multi-billion-dollar-industry-now-known-3d-printing-133978/ | archive-date=2020-07-28 }}</ref> | |||

| <ref name="Olliver-2">{{cite web | url=https://3dprintingindustry.com/news/interview-vik-olliver-first-reprap-volunteer-didnt-just-build-3d-printer-133892/ | title=Interview: Vik Olliver, the first RepRap volunteer – 'We didn't just build a 3D printer' | date=29 May 2018 | archive-url=https://web.archive.org/web/20200221110108/https://3dprintingindustry.com/news/interview-vik-olliver-first-reprap-volunteer-didnt-just-build-3d-printer-133892 | archive-date=2020-02-21 }}</ref> | |||

| <ref name="AMPS-Project">{{cite web | url=http://www.bath.ac.uk/idmrc/themes/projects/amps/AMPS-Project-RepRap.pdf | title=RepRap—the Replication Rapid Prototyper Project, IdMRC | access-date=2007-02-19 | url-status=dead | archive-url=https://web.archive.org/web/20120406095923/http://www.bath.ac.uk/idmrc/themes/projects/amps/AMPS-Project-RepRap.pdf | archive-date=2012-04-06 }}</ref> | |||

| <ref name="Schelly">{{Cite journal | doi=10.1016/j.jvlc.2015.01.004| title=Open-source 3-D printing technologies for education: Bringing additive manufacturing to the classroom| journal=Journal of Visual Languages & Computing| volume=28| pages=226–237| year=2015| last1=Schelly| first1=Chelsea| last2=Anzalone| first2=Gerald| last3=Wijnen| first3=Bas| last4=Pearce| first4=Joshua M.| url=https://digitalcommons.mtu.edu/materials_fp/47}}</ref> | |||

| <ref name="Grujović">Grujović, N., Radović, M., Kanjevac, V., Borota, J., Grujović, G., & Divac, D. (2011, September). 3D printing technology in education environment. ''In 34th International Conference on Production Engineering'' (pp. 29-30).</ref> | |||

| <ref name="Mercuri">Mercuri, R., & Meredith, K. (2014, March). An educational venture into 3D Printing. In Integrated STEM Education Conference (ISEC), 2014 IEEE (pp. 1-6). IEEE.</ref> | |||

| <ref name="Gonzalez-Gomez">Gonzalez-Gomez, J., Valero-Gomez, A., Prieto-Moreno, A., & Abderrahim, M. (2012). A new open source 3d-printable mobile robotic platform for education. In ''Advances in autonomous mini robots'' (pp. 49-62). Springer Berlin Heidelberg.</ref> | |||

| <ref name="Irwin">J. Irwin, J.M. Pearce, D. Opplinger, and G. Anzalone. , ''121st ASEE Annual Conference and Exposition, Indianapolis, IN''. Paper ID #8696 (2014).</ref> | |||

| }} | |||

| == References == | == References == | ||

| Line 124: | Line 158: | ||

| {{refbegin}} | {{refbegin}} | ||

| * . ''New Electronics'', 12 December 2006. | * . ''New Electronics'', 12 December 2006. | ||

| * . Celeste Biever, ''New Scientist'', 18 March 2005 | * . Celeste Biever, ''New Scientist'', 18 March 2005 | ||

| * . Simon Hooper, ], 2 June 2005 | * . Simon Hooper, ], 2 June 2005 | ||

| * . KnowProSE.com, 5 June 2005 | * . KnowProSE.com, 5 June 2005 | ||

| * , September 2006 | * , September 2006 | ||

| * | * | ||

| * | * | ||

| {{refend}} | {{refend}} | ||

| Line 136: | Line 170: | ||

| * {{Official website|http://reprap.org/}} | * {{Official website|http://reprap.org/}} | ||

| * on RepRap | * on RepRap | ||

| {{3d printing}} | |||

| ] | ] | ||

| ] | ] | ||

| ] | ] | ||

| ] | |||

| ] | |||

| ] | |||

Latest revision as of 20:28, 10 January 2025

Self-replicating 3D printer initiative

RepRap (a contraction of replicating rapid prototyper) is a project to develop low-cost 3D printers that can print most of their own components. As open designs, all of the designs produced by the project are released under a free software license, the GNU General Public License.

Due to the ability of these machines to make some of their own parts, authors envisioned the possibility of cheap RepRap units, enabling the manufacture of complex products without the need for extensive industrial infrastructure. They intended for the RepRap to demonstrate evolution in this process as well as for it to increase in number exponentially. A preliminary study claimed that using RepRaps to print common products results in economic savings.

The RepRap project started in England in 2005 as a University of Bath initiative, but it is now made up of hundreds of collaborators worldwide.

History

RepRap was founded in 2005 by Adrian Bowyer, a Senior Lecturer in mechanical engineering at the University of Bath in England. Funding was obtained from the Engineering and Physical Sciences Research Council.

On 13 September 2006, the RepRap 0.2 prototype printed the first part identical to its own, which was then substituted for the original part created by a commercial 3D printer. On 9 February 2008, RepRap 1.0 "Darwin" made at least one instance of over half its rapid-prototyped parts. On 14 April 2008, RepRap made an end-user item: a clamp to hold an iPod to the dashboard of a Ford Fiesta car. By September that year, at least 100 copies had been produced in various countries. On 29 May 2008, Darwin achieved self replication by making a complete copy of all its rapid-prototyped parts (which represent 48% of all the parts, excluding fasteners). A couple hours later the "child" machine had made its first part: a timing-belt tensioner.

In April 2009, electronic circuit boards were produced automatically with a RepRap, using an automated control system and a swappable head system capable of printing both plastic and conductive solder. On 2 October 2009, the second generation design, called Mendel, printed its first part. Mendel's shape resembles a triangular prism rather than a cube. Mendel was completed in October 2009. On 27 January 2010, the Foresight Institute announced the "Kartik M. Gada Humanitarian Innovation Prize" for the design and construction of an improved RepRap.

On 31 August 2010, the third generation design was named Huxley. It was a miniature of Mendel, with 30% of the original print volume. Within two years, RepRap and RepStrap building and use were widespread in the technology, gadget and engineering communities.

In 2012, the first successful Delta design, Rostock, had a radically different design. The latest iterations used OpenBeams, wires (typically Dyneema or Spectra fishing lines) instead of belts, and so forth, which also represented some of the latest trends in RepRaps.

In early January 2016, RepRapPro (short for "RepRap Professional", and one commercial arm of the RepRap project in the UK) announced that it would cease trading on 15 January 2016. The reason given was congestion of the market for low-cost 3D printers and the inability to expand in that market. RepRapPro China continues to operate.

Hardware

As the project was designed by Bowyer to encourage evolution, many variations have been created. As an open source project, designers are free to make modifications and substitutions, but they must allow any of their potential improvements to be reused by others.

There are many RepRap printer designs including:

- Prusa i3

- Hangprinter

- RepRap Fisher

- RepRap Snappy

- RepRap Morgan

- RepRap Ormerod

- RepRap Darwin

- RepRap Mendel

Software

RepRap was conceived as a complete replication system rather than simply a piece of hardware. To this end the system includes computer-aided design (CAD) in the form of a 3D modeling system and computer-aided manufacturing (CAM) software and drivers that convert RepRap users' designs into a set of instructions to the RepRap to create physical objects.

Initially, two CAM tool chains were developed for RepRap. The first, called "RepRap Host", was written in Java by lead RepRap developer Adrian Bowyer. The second, "Skeinforge", was written by Enrique Perez. Both are complete systems for translating 3D computer models into G-code, the machine language that commands the printer.

Later, other programs like Slic3r and Cura were created. Recently, the Franklin firmware was created to allow RepRap printers to be used for other purposes such as milling and fluid handling.

Free and open-source 3-D modeling programs like Blender, OpenSCAD, and FreeCAD are preferred in the RepRap community, but almost any CAD or 3D modeling program can be used with the RepRap, as long as it can produce STL files (Slic3r also supports .obj and .amf files). Thus, content creators make use of any tools they are familiar with, whether they are commercial CAD programs, such as SolidWorks and Autodesk AutoCAD, Autodesk Inventor, Tinkercad, or SketchUp along with the libre software.

Replication materials

RepRaps print objects from ABS, Polylactic acid (PLA), Nylon (possibly not all extruders can), HDPE, TPE and similar thermoplastics.

The mechanical properties of RepRap-printed PLA and ABS have been tested and are equivalent to the tensile strengths of parts made by proprietary printers.

Unlike with most commercial machines, RepRap users are encouraged to experiment with materials and methods, and to publish their results. Methods for printing novel materials (such as ceramics) have been developed this way. In addition, several RecycleBots have been designed and fabricated to convert waste plastic, such as shampoo containers and milk jugs, into inexpensive RepRap filament. There is some evidence that using this approach of distributed recycling is better for the environment and can be useful for creating "fair trade filament".

In addition, 3D printing products at the point of consumption has also been shown to be better for the environment.

The RepRap project has identified polyvinyl alcohol (PVA) as a potentially suitable support material to complement its printing process, although massive overhangs can be made by extruding thin layers of the primary printing media as support (these are mechanically removed afterwards).

Printing electronics is a major goal of the RepRap project so that it can print its own circuit boards. Several methods have been proposed:

- Wood's metal or Field's metal: low-melting point metal alloys to incorporate electrical circuits into the part as it is being formed.

- Silver/carbon-filled polymers: commonly used to repair circuit boards and are being considered for use for electrically conductive traces.

- Direct extrusion of solder

- Conductive wires: can be laid into a part from a spool during the printing process

Using a MIG welder as a print head a RepRap deltabot stage can be used to print metals like steel.

The RepRap concept can also be applied to a milling machine and to laser welding.

Construction

Although the aim of the project is for RepRap to be able to autonomously construct many of its own mechanical components soon using fairly low-level resources, several components such as sensors, stepper motors and microcontrollers cannot yet be made using the RepRap's 3D printing technology and so have to be produced independently. The plan is to approach 100% replication over a series of versions. For example, from the onset of the project, the RepRap team has explored a variety of approaches to integrating electrically-conductive media into the product. This would allow inclusion of connective wiring, printed circuit boards, and possibly motors in RepRapped products. Variations in the nature of the extruded, electrically-conductive media could produce electrical components with different functions from pure conductive traces, similar to the 1940s sprayed-circuit process Electronic Circuit Making Equipment (ECME), by John Sargrove. A related approach is printed electronics. Another non-replicable component is the threaded rods for linear motions. A current research area is in using replicated Sarrus linkages to replace them.

Project members

The "Core team" of the project has included:

- Adrian Bowyer, Former Senior Lecturer, Mechanical Engineering Department, University of Bath

- Ed Sells, University of Bath PhD "3D Printing: Towards a Self-Replicating Rapid Prototyping Machine"

- Vik Olliver, the first RepRap volunteer, the first to suggest using PLA as a printing material

- Michael S. Hart (deceased 2011), creator of Project Gutenberg, Illinois

Goals

The stated goal of the RepRap project is to produce a pure self-replicating device not for its own sake, but rather to put in the hands of individuals anywhere on the planet, for a minimal outlay of capital, a desktop manufacturing system that would enable the individual to manufacture many of the artifacts used in everyday life. From a theoretical viewpoint, the project aims to prove the hypothesis that "rapid prototyping and direct writing technologies are sufficiently versatile to allow them to be used to make a von Neumann universal constructor".

Education

RepRap technology has great potential in educational applications, according to some scholars. RepRaps have already been used for an educational mobile robotics platform. Some authors have claimed that RepRaps offer an unprecedented "revolution" in STEM education. The evidence comes from both the low cost of rapid prototyping by students, and the fabrication of low-cost high-quality scientific equipment from open hardware designs forming open-source labs.

See also

- 3D printing processes

- Comparison of 3D printers

- Disruptive technology

- Fab lab

- Fab@Home

- Recyclebot

- Self-replicating machine

- Voron 2.4 (2020), a CoreXY printer described as a resurgence of the RepRap project

Notes

- "RepRapGPLLicence - RepRap".

- Pearce, Joshua M.; Morris Blair, Christine; Laciak, Kristen J.; Andrews, Rob; Nosrat, Amir; Zelenika-Zovko, Ivana (2010). "3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development". Journal of Sustainable Development. 3 (4). doi:10.5539/jsd.v3n4p17.

- ^ Pearce, Joshua M (2012). "Building Research Equipment with Free, Open-Source Hardware". Science. 337 (6100): 1303–1304. Bibcode:2012Sci...337.1303P. doi:10.1126/science.1228183. PMID 22984059. S2CID 44722829.

- ^ J.M. Pearce, Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs, Elsevier, 2014.

- ^ Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. (2011). "Reprap-- the replicating rapid prototyper". Robotica. 29 (1): 177–191. doi:10.1017/s026357471000069x.

- Sells, E., Smith, Z., Bailard, S., Bowyer, A., & Olliver, V. (2009). Reprap: the replicating rapid prototyper: maximizing customizability by breeding the means of production. Handbook of Research in Mass Customization and Personalization.

- Wittbrodt, B.T.; Glover, A.G.; Laureto, J.; Anzalone, G.C.; Oppliger, D.; Irwin, J.L.; Pearce, J.M. (2013). "Life-cycle economic analysis of distributed manufacturing with open-source 3-D printers" (PDF). Mechatronics. 23 (6): 713–726. doi:10.1016/j.mechatronics.2013.06.002. S2CID 1766321. http://digitalcommons.mtu.edu/cgi/viewcontent.cgi?article=1048&context=materials_fp

- Matthew Power (23 September 2008). "Mechanical Generation §". Seedmagazine. Archived from the original on 25 September 2008. Retrieved 4 June 2010.

- Vik Olliver (27 May 2021). "Tomorrow is RepRap Day. On that day in 2008 a 3D printer first achieved self-replication. I may have assisted it slightly" (Tweet) – via Twitter.

- "Gada Prizes". humanity+. Archived from the original on 29 July 2012. Retrieved 25 April 2011.

- "Ingeniøren". Ingeniøren media. 26 September 2012. Archived from the original on 15 October 2012. Retrieved 26 September 2012.

- "RepRap Professional Ltd. is now closed". 6 January 2016.

- RepRap Family Tree

- Chulilla, J. L. (2011). "The Cambrian Explosion of Popular 3D Printing". International Journal of Interactive Multimedia and Artificial Intelligence. 1: 4.

- Skeinforge

- Wijnen, Bas; Anzalone, Gerald C.; Haselhuhn, Amberlee S.; Sanders, P. G.; Pearce, Joshua M. (2016). "Free and Open-source Control Software for 3-D Motion and Processing". Journal of Open Research Software. 4: 2. doi:10.5334/jors.78.

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. (2014). "Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions". Materials & Design. 58: 242–246. doi:10.1016/j.matdes.2014.02.038. S2CID 15552570.

- Baechler, Christian; DeVuono, Matthew; Pearce, Joshua M. (2013). "Distributed Recycling of Waste Polymer into RepRap Feedstock". Rapid Prototyping Journal. 19 (2): 118–125. doi:10.1108/13552541311302978. S2CID 15980607.

- Kreiger, M., Anzalone, G. C., Mulder, M. L., Glover, A., & Pearce, J. M. (2013). Distributed Recycling of Post-Consumer Plastic Waste in Rural Areas. MRS Online Proceedings Library, 1492, mrsf12-1492. open access

- The importance of the Lyman Extruder, Filamaker, Recyclebot and Filabot to 3D printing Archived 2014-03-18 at the Wayback Machine – VoxelFab, 2013.

- M. Kreiger, G. C. Anzalone, M. L. Mulder, A. Glover and J. M Pearce (2013). Distributed Recycling of Post-Consumer Plastic Waste in Rural Areas. MRS Online Proceedings Library, 1492, mrsf12-1492-g04-06 doi:10.1557/opl.2013.258. open access

- Feeley, S. R.; Wijnen, B.; Pearce, J. M. (2014). "Evaluation of Potential Fair Trade Standards for an Ethical 3-D Printing Filament". Journal of Sustainable Development. 7 (5): 1–12. doi:10.5539/jsd.v7n5p1.

- Kreiger, Megan; Pearce, Joshua M. (2013). "Environmental Life Cycle Analysis of Distributed Three-Dimensional Printing and Conventional Manufacturing of Polymer Products". ACS Sustainable Chemistry & Engineering. 1 (12): 1511–1519. doi:10.1021/sc400093k.

- Simon J. Leigh, Robert J. Bradley, Christopher P. Purssell, Duncan R. Billson, David A. Hutchins A Simple, Low-Cost Conductive Composite Material for 3D Printing of Electronic Sensors

- RepRap blog 2009 visited 2/26/2014

- An Inexpensive Way to Print Out Metal Parts - The New York Times

- Anzalone, Gerald C.; Chenlong Zhang; Wijnen, Bas; Sanders, Paul G.; Pearce, Joshua M. (2013). "A Low-Cost Open-Source Metal 3-D Printer". IEEE Access. 1: 803–810. Bibcode:2013IEEEA...1..803A. doi:10.1109/ACCESS.2013.2293018.

- Kostakis, V., & Papachristou, M. (2013). Commons-based peer production and digital fabrication: The case of a RepRap-based, Lego-built 3D printing-milling machine. Telematics and Informatics.

- Laureto, John; Dessiatoun, Serguei; Ohadi, Michael; Pearce, Joshua (2016). "Open Source Laser Polymer Welding System: Design and Characterization of Linear Low-Density Polyethylene Multilayer Welds". Machines. 4 (3): 14. doi:10.3390/machines4030014.

- "I, replicator". New Scientist. 29 May 2010.

- "The Core Team - who we are" Archived 2013-04-06 at the Wayback Machine, reprap.org/wiki

- Petch, Michael (31 May 2018). "Interview: Ed Sells, RepRap 'opened up a multi-billion dollar industry now known as 3D printing'". 3D Printing Industry. Archived from the original on 28 July 2020.

- "Interview: Vik Olliver, the first RepRap volunteer – 'We didn't just build a 3D printer'". 29 May 2018. Archived from the original on 21 February 2020.

- "RepRap—the Replication Rapid Prototyper Project, IdMRC" (PDF). Archived from the original (PDF) on 6 April 2012. Retrieved 19 February 2007.

- Schelly, Chelsea; Anzalone, Gerald; Wijnen, Bas; Pearce, Joshua M. (2015). "Open-source 3-D printing technologies for education: Bringing additive manufacturing to the classroom". Journal of Visual Languages & Computing. 28: 226–237. doi:10.1016/j.jvlc.2015.01.004.

- Grujović, N., Radović, M., Kanjevac, V., Borota, J., Grujović, G., & Divac, D. (2011, September). 3D printing technology in education environment. In 34th International Conference on Production Engineering (pp. 29-30).

- Mercuri, R., & Meredith, K. (2014, March). An educational venture into 3D Printing. In Integrated STEM Education Conference (ISEC), 2014 IEEE (pp. 1-6). IEEE.

- Gonzalez-Gomez, J., Valero-Gomez, A., Prieto-Moreno, A., & Abderrahim, M. (2012). A new open source 3d-printable mobile robotic platform for education. In Advances in autonomous mini robots (pp. 49-62). Springer Berlin Heidelberg.

- J. Irwin, J.M. Pearce, D. Opplinger, and G. Anzalone. The RepRap 3-D Printer Revolution in STEM Education, 121st ASEE Annual Conference and Exposition, Indianapolis, IN. Paper ID #8696 (2014).

References

- Replication revolutionary. New Electronics, 12 December 2006.

- 3D printer to churn out copies of itself. Celeste Biever, New Scientist, 18 March 2005

- The machine that can copy anything. Simon Hooper, CNN, 2 June 2005

- Self Replicating Robots And The Developing World. KnowProSE.com, 5 June 2005

- Interview with Vik Olliver about RepRap, September 2006

- Chinese Growth Hurdles toward a New Great Wall

- Canadian Broadcasting Corporation audio interview with Adrian Bowyer

External links

| 3D printing technologies | |

|---|---|

| Resin photopolymerization | |

| Material extrusion | |

| Powder bed binding/fusion | |

| Sheet lamination | |

| Directed energy deposition | |

| Building printing | |

| Related topics | |