| Revision as of 17:06, 16 July 2018 editGuiding light (talk | contribs)Extended confirmed users5,905 edits →Polarization impacts on immersion lithography← Previous edit | Revision as of 17:12, 16 July 2018 edit undoGuiding light (talk | contribs)Extended confirmed users5,905 edits →Polarization impacts on immersion lithographyNext edit → | ||

| Line 28: | Line 28: | ||

| ==Polarization impacts on immersion lithography== | ==Polarization impacts on immersion lithography== | ||

| Polarization effects due to high angles of interference in the photoresist also have to be considered as features approach 40 nm.<ref>C. Wagner ''et al.'', Proc. SPIE vol. 4000, pp. 344-357 (2000).</ref> Hence, illumination sources generally will need to be azimuthally polarized to match the pole illumination for ideal line-space imaging. | Polarization effects due to high angles of interference in the photoresist also have to be considered as features approach 40 nm.<ref>C. Wagner ''et al.'', Proc. SPIE vol. 4000, pp. 344-357 (2000).</ref> Hence, illumination sources generally will need to be azimuthally polarized to match the pole illumination for ideal line-space imaging.<ref>B. W. Smith, L. V. Zavyalova, and A. Estroff, Proc. SPIE 5377 (2004).</ref> | ||

| ==Throughput of immersion lithography== | ==Throughput of immersion lithography== | ||

Revision as of 17:12, 16 July 2018

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

|

Immersion lithography is a photolithography resolution enhancement technique for manufacturing integrated circuits (ICs) that replaces the usual air gap between the final lens and the wafer surface with a liquid medium that has a refractive index greater than one. The resolution is increased by a factor equal to the refractive index of the liquid. Current immersion lithography tools use highly purified water for this liquid, achieving feature sizes below 45 nanometers. ASML and Nikon are currently the only manufacturers of immersion lithography systems. The idea for Immersion lithography was first proposed and realized in the 1980s.

Benefits of immersion lithography

The ability to resolve features in optical lithography is directly related to the numerical aperture of the imaging equipment, the numerical aperture being the sine of the maximum refraction angle multiplied by the refractive index of the medium through which the light travels. The lenses in the highest resolution "dry" photolithography scanners focus light in a cone whose boundary is nearly parallel to the wafer surface. As it is impossible to increase resolution by further refraction, additional resolution is obtained by inserting an immersion medium with a higher index of refraction between the lens and the wafer. The blurriness is reduced by a factor equal to the refractive index of the medium. For example, for water immersion using ultraviolet light at 193 nm wavelength, the index of refraction is 1.44.

The resolution enhancement from immersion lithography is about 30-40% (depending on materials used). However, the depth of focus, or tolerance in wafer topography flatness, is reduced compared to the corresponding "dry" tool at the same resolution.

Immersion lithography is now being extended to sub-20nm nodes through the use of multiple patterning.

Manufacturing issues

The main obstacle to adoption of immersion lithography systems has been defects and other possible sources of yield loss. Early studies focused on the elimination of bubbles in the immersion fluid, temperature and pressure variations in the immersion fluid, and immersion fluid absorption by the photoresist. Degassing the fluid, carefully constraining the fluid thermodynamics and carefully treating the top layer of photoresist have been key to the implementation of immersion lithography. Defects intrinsic to immersion lithography have been identified. Reducing particle generation due to the water dispensing unit was found to reduce the incidence of defects. Water also has been shown to extract acid from photoresist. Specifically, photoacid generators (PAGs) are extracted into the water, which produce acid upon radiation exposure. This must be managed to ensure the lens is not corroded by the acid or contaminated by the extracted agents, and the photoresist is not chemically altered to the point of being defective. Still, since diffusion of contaminants is expected to be much slower in water than in air or vacuum, consideration of optics contamination actually favors immersion lithography. Water-soaked photoresist also has been demonstrated to produce very satisfactory images.

In addition, 193 nm light has been known to ionize water, producing solvated electrons, which may spread and react with the photoresist, affecting the resolution performance.

The above defect concerns have led to considerations of using a topcoat layer directly on top of the photoresist. This topcoat would serve as a barrier for chemical diffusion between the liquid medium and the photoresist. In addition, the interface between the liquid and the topcoat would be optimized for watermark reduction. At the same time, defects from topcoat use should be avoided.

As scanning speeds typically approach or even exceed 500 mm/s for high-volume manufacturing, the actual resist-water contact time in any given exposure area is minimal. Hence the main concerns for defects are water left behind (watermarks) and loss of resist-water adhesion (air gap). The hydrophobicity of the surface and the water delivery/removal method are therefore the key areas to address. Other areas where defects may be enhanced are at the wafer edge, where the water has to do an "about-face" (reverse motion). It is important for the water not to pick up defects from the wafer backside.

Generally, implementation into manufacturing is only considered when defect yields reach a mature level, e.g., comparable to dry lithography levels.

Polarization impacts on immersion lithography

Polarization effects due to high angles of interference in the photoresist also have to be considered as features approach 40 nm. Hence, illumination sources generally will need to be azimuthally polarized to match the pole illumination for ideal line-space imaging.

Throughput of immersion lithography

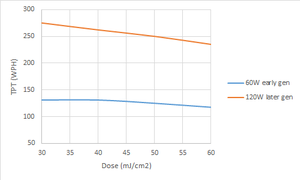

Immersion lithography tools currently boast the highest throughputs (275 WPH). This is achieved through higher stage speeds, which in turn, are allowed by higher power ArF laser pulse sources.

References

- DailyTech - IDF09 Intel Demonstrates First 22nm Chips Discusses Die Shrink Roadmap

- Burn J. Lin (1987). "The future of subhalf-micrometer optical lithography". Microelectronic Engineering 6, 31–51

- M. Switkes et al., J. Vac. Sci. & Tech. B vol. 21, pp. 2794-2799 (2003).

- U. Okoroanyanwu et al., "Defectivity in water immersion lithography," Microlithography World, November 2005.

- J. C. Taylor et al., SPIE vol. 5376, pp. 34-43 (2004).

- A. K. Raub et al., J. Vac. Sci. & Tech. B vol. 22, pp. 3459-3464 (2004).

- A. Iwata et al., Chem. Lett., vol. 22, 1939 (1993).

- C. Wagner et al., Proc. SPIE vol. 4000, pp. 344-357 (2000).

- B. W. Smith, L. V. Zavyalova, and A. Estroff, Proc. SPIE 5377 (2004).

- NXT:1980Di