This is an old revision of this page, as edited by ZéroBot (talk | contribs) at 16:45, 13 August 2011 (r2.7.1) (robot Adding: fr:Disulfure de molybdène). The present address (URL) is a permanent link to this revision, which may differ significantly from the current revision.

Revision as of 16:45, 13 August 2011 by ZéroBot (talk | contribs) (r2.7.1) (robot Adding: fr:Disulfure de molybdène)(diff) ← Previous revision | Latest revision (diff) | Newer revision → (diff)

| |

| |

| Names | |

|---|---|

| IUPAC name Molybdenum disulfide | |

| Other names Molybdenite | |

| Identifiers | |

| CAS Number | |

| 3D model (JSmol) | |

| ChEBI | |

| ChemSpider | |

| ECHA InfoCard | 100.013.877 |

| RTECS number |

|

| CompTox Dashboard (EPA) | |

InChI

| |

SMILES

| |

| Properties | |

| Chemical formula | MoS2 |

| Molar mass | 160.07 g/mol |

| Appearance | black solid |

| Density | 5.06 g/cm |

| Melting point | 1185 °C decomp. |

| Structure | |

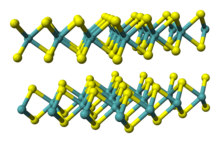

| Crystal structure | Hexagonal, hP6, space group P63/mmc, No 194 |

| Coordination geometry | Trigonal prismatic (Mo) Pyramidal (S) |

| Related compounds | |

| Other anions | Molybdenum(IV) oxide |

| Other cations | Tungsten disulfide |

| Except where otherwise noted, data are given for materials in their standard state (at 25 °C , 100 kPa).

| |

Molybdenum disulfide is the inorganic compound with the formula MoS2. This black crystalline sulfide of molybdenum occurs as the mineral molybdenite. It is the principal ore from which molybdenum metal is extracted. The natural amorphous form is known as the rarer mineral jordisite. MoS2 is less reactive than other transition metal chalcogenides, being unaffected by dilute acids. In its appearance and feel, molybdenum disulfide is similar to graphite. Indeed, like graphite, it is widely used as a solid lubricant because of its low friction properties, sometimes to relatively high temperatures.

Production

Molybdenite ore is processed by flotation to give relatively pure MoS2, the main contaminant being carbon. MoS2 also arises by the thermal treatment of virtually all molybdenum compounds with hydrogen sulfide. Molybdenite is the principal ore from which molybdenum metal is extracted.

Structure and physical properties

In MoS2, each Mo(IV) center occupies a trigonal prismatic coordination sphere, being bound to six sulfide ligands. Each sulfur centre is pyramidal, being connected to three Mo centres. In this way, the trigonal prisms are interconnected to give a layered structure, wherein molybdenum atoms are sandwiched between layers of sulfur atoms. Because of the weak van der Waals interactions between the sheets of sulfide atoms, MoS2 has a low coefficient of friction, resulting in its lubricating properties. Other layered inorganic materials exhibit lubricating properties (collectively known as solid lubricants or dry lubricants) including graphite, which requires volatile additives, and hexagonal boron nitride.

MoS2 is diamagnetic and a semiconductor.

Chemical properties

Molybdenum disulfide is stable in air or oxygen at normal conditions, but reacts with oxygen upon heating forming molybdenum trioxide:

- 2 MoS2 + 9 O2 → 2 MoO3 + 4 SO3

Chlorine attacks molybdenum disulfide at elevated temperatures to form molybdenum pentachloride:

- 2 MoS2 + 7 Cl2 → 2 MoCl5 + 2 S2Cl2

Molybdenum disulfide reacts with alkyl lithium under controlled conditions to form intercalation compounds LixMoS2. With butyl lithium, the product is LiMoS2.

Use as lubricant

MoS2 with particle sizes in the range of 1–100 µm is a common dry lubricant. Few alternatives exist that can confer the high lubricity and stability up to 350 °C in oxidizing environments. Sliding friction tests of MoS2 using a pin on disc tester at low loads (0.1–2 N) give friction coefficient values of <0.1.

Molybdenum disulfide is often a component of blends and composites where low friction is sought. A variety of oils and greases are used, because they retain their lubricity even in cases of almost complete oil loss, thus finding a use in critical applications such as aircraft engines. When added to plastics, MoS2 forms a composite with improved strength as well as reduced friction. Polymers that have been filled with MoS2 include nylon (with the trade name Nylatron), Teflon, and Vespel. Self-lubricating composite coatings for high-temperature applications have been developed consisting of molybdenum disulfide and titanium nitride by chemical vapor deposition.

Specific uses

MoS2 is often used in two-stroke engines; e.g., motorcycle engines. It is also used in CV and universal joints. MoS2-coatings allow bullets easier passage through the rifle barrel causing less barrel fouling allowing the barrel to retain ballistic accuracy much longer. This resistance to barrel fouling comes at a cost of lower muzzle velocity with the same load due to a decreased chamber pressure.MoS2 is applied to bearings in ultra-high vacuum applications up to 10 torr (at −226 to 399 °C). The lubricant is applied by burnishing and the excess is wiped from the bearing surface.

MoS2 is also used in ski glide wax. Many ski wax manufacturers use it now to prevent static buildup in dry snow conditions and to add glide when sliding in dirty snow.

Use in petrochemistry

Synthetic MoS2 is employed as a catalyst for desulfurization in petroleum refineries; e.g., hydrodesulfurization. The effectiveness of the MoS2 catalysts is enhanced by doping with small amounts of cobalt or nickel and the intimate mixture is supported on alumina. Such catalysts are generated in situ by treating molybdate/cobalt or nickel-impregnated alumina with H2S or an equivalent reagent.

Future developments

Lubrication

With the exception of hexagonal boron nitride, there are currently no clear lubrication alternatives to molybdenum disulfide or the very similar tungsten disulfide that can resist temperatures higher than 350 °C in oxidizing environments. Research has been conducted on compacted oxide layer glazes, which form during metallic surface sliding wear at several hundred degrees Celsius. However, because these oxide layers are physically unstable, their use has currently not proven practical.

Photocatalyst

When combined with cadmium sulfide, MoS2 increases the rate of photocatalytic hydrogen production.

Electronics

Molybdenum disulfide has been found to have semi-conductive properties with distinct advantages over traditional silicon or germanium for use in electronics applications.

References

- ^ Roger F. Sebenik et al. "Molybdenum and Molybdenum Compounds" in Ullmann's Encyclopedia of Chemical Technology 2005; Wiley-VCH, Weinheim. doi:10.1002/14356007.a16_655

- Wells, A.F. (1984). Structural Inorganic Chemistry. Oxford: Clarendon Press. ISBN 0-19-855370-6.

- Thorsten Bartels; et al. (2002). "Lubricants and Lubrication". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley VCH. doi:10.1002/14356007.a15_423.

{{cite book}}: Explicit use of et al. in:|author=(help) - G. L. Miessler and D. A. Tarr (2004). Inorganic Chemistry, 3rd Ed. Pearson/Prentice Hall publisher. ISBN 0-13-035471-6.

- Shriver, D. F.; Atkins, P. W.; Overton, T. L.; Rourke, J. P.; Weller, M. T.; Armstrong, F. A. (2006). Inorganic Chemistry. New York: W. H. Freeman. ISBN 0-7167-4878-9.

{{cite book}}: CS1 maint: multiple names: authors list (link) - "ORNL develops self-lubricating coating for engine parts". Retrieved 2009-06-06.

- "Barrels retain accuracy longer with Diamond Line". Norma. Retrieved 2009-06-06.

- "DOW CORNING Z moly-powder" (PDF). Dow Corning. Retrieved 2009-08-18.

- "On dry lubricants in ski waxes" (PDF). Swix Sport AX. Retrieved 2011-01-06.

- "GENERAL INFORMATION ON WAX". Toko. Retrieved 2011-01-06.

- Topsøe, H.; Clausen, B. S.; Massoth, F. E. (1996). Hydrotreating Catalysis, Science and Technology. Berlin: Springer-Verlag.

{{cite book}}: CS1 maint: multiple names: authors list (link) - "CAS researchers discover low-cost photocatalyst for H2 production". Chinese Academy of Sciences. Retrieved 2009-06-06.

- "New transistors: An alternative to silicon and better than graphene". Physorg.com. January 30, 2011. Retrieved January 30, 2011.

Further reading

- W. Müller-Warmuth, R. Schöllhorn (1994). Progress in intercalation research. Springer. p. 50. ISBN 0792323572.

| Molybdenum compounds | |

|---|---|

| Mo(0) | |

| Mo(II) | |

| Mo(III) | |

| Mo(IV) | |

| Mo(V) | |

| Mo(VI) | |