| Revision as of 00:05, 20 October 2007 editKappa (talk | contribs)36,858 edits don't seem to be any {{otheruses}}← Previous edit | Latest revision as of 21:13, 11 November 2024 edit undoEewilson (talk | contribs)Extended confirmed users21,207 edits remove dead link | ||

| (383 intermediate revisions by more than 100 users not shown) | |||

| Line 1: | Line 1: | ||

| {{Short description|Species of plant}} | |||

| {{Taxobox | |||

| {{Redirect-distinguish|Abacas|Abacus}} | |||

| | color = lightgreen | |||

| {{Use mdy dates|date=October 2022}} | |||

| | name = Abaca | |||

| {{Use Philippine English|date=October 2022}} | |||

| | status = | |||

| {{Speciesbox | |||

| | name = Abacá<br/>''Musa textilis'' | |||

| secure | |||

| | image = Musa textilis |

| image = Musa textilis 7zz.jpg | ||

| | image_caption = At the ] | |||

| | image_width = 240px | |||

| | |

| genus = Musa | ||

| | parent = Musa sect. Callimusa | |||

| | divisio = ] | |||

| | species = textilis | |||

| | classis = ] | |||

| | |

| authority = ] | ||

| | synonyms = | |||

| | familia = ] | |||

| {{Collapsible list | | |||

| | genus = '']'' | |||

| {{Plainlist | style = margin-left: 1em; text-indent: -1em; | | |||

| | species = '''''M. textilis''''' | |||

| *''Musa abaca'' <small>]</small>{{sfn|Bailey|1947}} nom. inval. | |||

| | binomial = ''Musa textilis'' | |||

| *''Musa amboinensis'' <small>Miquel</small> | |||

| | binomial_authority = ] | |||

| *''Musa mindanaensis'' <small>]</small> | |||

| *''Musa mindanensis'' <small>]</small>{{sfn|Bailey|1947|p=2078}} | |||

| *''Musa silvéstris'' <small>]</small>{{sfn|Bailey|1947}} | |||

| *''Musa tikap'' <small>]</small> | |||

| *''Musa troglodytàrum textòria'' <small>]</small>{{sfn|Bailey|1947}} | |||

| }} | |||

| }} | |||

| | synonyms_ref = <ref>{{harvnb|Anon|2013}}</ref> | |||

| }} | }} | ||

| '''Abacá''' ({{IPAc-en|ɑː|b|ə|ˈ|k|ɑː}} {{respell|ah-bə|KAH|'}}; {{langx|fil|abaka}} {{IPA|tl|ɐbɐˈka|}}), also known as '''Manila hemp''', is a species of ], '''''Musa textilis''''', endemic to the ]. The plant grows to {{convert|13|-|22|ft|m}}, and averages about {{convert|12|ft|m}}. The plant has great economic importance, being harvested for its ] extracted from the leaf-stems.<ref name="edwards"/><ref>{{GRIN | ''Musa textilis'' | 24742 | accessdate = 5 June 2014}}</ref><ref name="hendrickx">{{cite journal|author=Katrien Hendrickx|year=1904|series=Studia anthropologica|volume=11|title=The Origins of Banana-fibre Cloth in the Ryukyus, Japan|journal=Farmers' Bulletin|isbn=978-90-5867-614-6|url=https://books.google.com/books?id=ULyu8dNqS1sC|page=170|publisher=Leuven University Press }}</ref> | |||

| '''Abacá''', from Spanish "abacá", pronounced {{IPA|}} (''"ah buh KAH"''), (''Musa textilis'') is a species of ] native to the ], grown widely as well in ] and ]. It is sometimes referred to as "BacBac". The plant is of great economic importance, being harvested for its fibre, called ], extracted from the large, oblong ] and stems. On average, the plant grows about 20 feet (6 meters) tall. The fibre is used for making twines and ropes. The plant's name is sometimes spelt '''Abaká'''. It was first cultivated on a large scale in ] in 1925 under the ], who had observed its cultivation in the Philippines for ] since the 1800s, followed up by plantings in ] sponsored by the ]<ref name="eb"> '']''. 22 January 2007</ref>. Commercial planting began in 1930 in ]; with the commencement of WWII, the supply from the Philippines was eliminated by the ]<ref name="eb"/>. | |||

| The lustrous fiber is traditionally hand-loomed into various indigenous textiles ('''abaca cloth''' or '''medriñaque''') in the Philippines. They are still featured prominently as the traditional material of the ], the national male attire of the Philippines, as well as in sheer lace-like fabrics called '']'' used in various clothing components. Native abaca textiles also survive into the modern era among various ethnic groups, like the '']'' of the ] and the ''dagmay'' of the ]. Abaca is also used in traditional Philippine ], as well as for bags, shawls, and other decorative items. The ] straw made from Manila hemp is called ''tagal'' or ''tagal straw''.<ref>{{cite book|last=Dreher|first=Denise|url=https://books.google.com/books?id=fc9x1E8J0wwC&q=Tagal|title=From the neck up : an illustrated guide to hatmaking|publisher=Madhatter|year=1981|isbn=9780941082006|edition=1st|location=Minneapolis, Minn.}}</ref><ref>{{cite book|last=Ginsburg|first=Madeleine|url=https://archive.org/details/hattrendstraditi00gins|title=The hat: trends and traditions|publisher=Barron's|year=1990|isbn=9780812061987|edition=1st U.S.|location=Hauppauge, N.Y.|quote=Tagal.|url-access=registration}}</ref> | |||

| Other common names for Manila hemp include "Cebu hemp" and "Davao hemp". | |||

| The fiber is also exceptionally strong, stronger than ] and naturally salt-resistant, making it ideal for making twines and ropes (especially for maritime shipping). It became a major trade commodity in the colonial era for this reason.<ref name="gdv">{{cite web|url=http://www.tis-gdv.de/tis_e/ware/fasern/manila/manila.htm|title=Manila hemp|publisher=Transport Information Service, Gesamtverband der Deutschen Versicherungswirtschaft e.V. |access-date=May 15, 2011}}</ref> The abaca industry declined sharply in the mid-20th century when abaca plantations were decimated by ] and plant diseases, as well as the invention of ] in the 1930s. Today, abaca is mostly used in a variety of specialized paper products including ]s, ] and ]s. ]s and ] derive their name from this fiber.<ref name="edwards">{{cite journal|author1=H. T. Edwards |author2=B. E. Brewer |author3=George E. Nesom |author4=Otis Warren Barrett |author4-link=Otis Warren Barrett |author5=William Scrugham Lyon |author6=Murad M. Saleeby |name-list-style=amp |year=1904|title=Abacá (manila hemp)|journal=Farmers' Bulletin|publisher=Bureau of Agriculture. Republic of the Philippines}}</ref><ref name="hendrickx"/> | |||

| ==Composition== | |||

| The leaves grow from the trunk of the plant, and the bases of the leaves form a ] (covering) around the trunk; there are approximately 25 of these, with 5 cm in diameter and from 12 to 25 leaves with overlapping ], covering the stalk to form a ], "false trunk" or pseudotrunk about 30 to 40 cm in diameter<ref name="eb"/>. They grow in succession, with the oldest growing from the bottom of the trunk and successively younger ones from the top. The sheaths contain the valuable fibre. The coarse fibres range from 5 to 11½ feet (1.5 to 3.5 metres) in length. They are composed primarily of the plant materials such as ], ], and ]. After the fibre has been separated, it is sold under the name ], the capital of the ]. | |||

| Abaca is classified as a ], along with ], ] and ]. Abaca is grown as a commercial crop in the Philippines, Ecuador, Costa Rica. | |||

| ==Harvesting== | |||

| ] | |||

| ==Description== | |||

| The plant is normally grown in well-drained loamy soil, using pieces of mature root planted at the start of the rainy season<ref name="eb"/>. Growers harvest abacá fields every three to eight months after an initial growth period of 18-25 months and a total lifespan of about 10 years<ref name="eb"/>. Harvest generally includes having several operations concerning the leaf sheaths: | |||

| The abacá plant is ], meaning that the plant produces runners or shoots along the ground that then root at each segment.{{sfn|Bailey|1947}} Cutting and transplanting rooted runners is the primary technique for creating new plants, since seed growth is substantially slower.{{refn|group=nb|A plant grown from a shoot takes three years to maturity; while a plant grown from a seed takes four years to maturity.<ref name=wor>{{harvnb|Worcester|1899|p=506}}</ref>}}<ref name=wood>{{harvnb|Wood|Roberts|2005|p=301}}</ref> Abacá has a "false trunk" or pseudostem about {{convert|6|-|15|in|cm}} in diameter.{{sfn|Bailey|1947}} The leaf stalks (]) are expanded at the base to form ]s that are tightly wrapped together to form the pseudostem. There are from 12 to 25 leaves, dark green on the top and pale green on the underside, sometimes with large brown patches. They are oblong in shape with a deltoid base.{{sfn|Bailey|1947}} They grow in succession. The petioles grow to at least {{convert|1|ft|cm}} in length.{{sfn|Bailey|1947}} | |||

| When the plant is mature, the flower stalk grows up inside the pseudostem. The male flower has five petals, each about {{convert|1.5|in|cm}} long.{{sfn|Bailey|1947}} The leaf sheaths contain the valuable fiber. After harvesting, the coarse fibers range in length from {{convert|6|-|12|ft|cm}} long.{{sfn|Bailey|1947}} They are composed primarily of ], ], and ]. | |||

| The fruit, which is inedible{{sfn|Bailey|1947}} and is rarely seen as harvesting occurs before the plant fruits, grows to about {{convert|2|-|3|in|cm}} in length and {{convert|1|in|cm}} in diameter.{{sfn|Bailey|1947}} It has black turbinate seeds that are {{convert|0.167|in|cm}} in diameter.{{sfn|Bailey|1947}} | |||

| ==Systematics== | |||

| The abacá plant belongs to the ] family, ]; it resembles the closely related wild seeded bananas, '']'' and '']''. Its scientific name is ''Musa textilis''. Within the ] '']'', it is placed in section ''Callimusa'' (now including the former section ''Australimusa''), members of which have a ] ] number of 2n'' ''= 20.<ref name=Wong02>{{harvnb|Wong|Kiew|Argent|Set|2002|p=234}}</ref> | |||

| == Genetic diversity == | |||

| The Philippines, especially the ] in Luzon, has the most abaca genotypes and cultivars. Genetic analysis using simple sequence repeats (SSR) markers revealed that the Philippines' abaca germplasm is genetically diverse.<ref name=":0">{{Cite web|last1=Yllano|first1= O. B.|last2= Diaz|first2= M. G. Q.|last3= Lalusin|first3= A. G.|last4= Laurena|first4= A. C.|last5= Tecson-Mendoza|first5= E. M.|date=2020|title=Genetic Analyses of Abaca (Musa textilis Née) Germplasm from its Primary Center of Origin, the Philippines, Using Simple Sequence Repeat (SSR) Markers – The Philippine Agricultural Scientist|url=https://pas.cafs.uplb.edu.ph/download/genetic-analyses-of-abaca-musa-textilis-nee-germplasm-from-its-primary-center-of-origin-the-philippines-using-simple-sequence-repeat-ssr-markers/|archive-url=|archive-date=|access-date=February 16, 2021|website=|language=en-US}}</ref> Abaca genotypes in Luzon had higher genetic diversity than Visayas and Mindanao.<ref name=":0" /> Ninety-five (95) percent was attributed to molecular variance within the population, and only 5% of the molecular variance to variation among populations.<ref name=":0" /> Genetic analysis by Unweighted Pair Group Method with Arithmetic Mean (UPGMA) revealed several clusters irrespective of geographical origin.<ref name=":0" /> | |||

| ==History== | |||

| ]]] | |||

| Before synthetic textiles came into use, ''M. textilis'' was a major source of high quality fiber: soft, silky and fine.<ref name=Ploe07>{{harvnb|Ploetz|Kepler|Daniells|Nelson|2007|p=4}}</ref> Ancestors of the modern abacá are thought to have originated from the eastern Philippines, where there is significant rainfall throughout the year. Wild varieties of abacá can still be found in the interior forests of the ] of ], away from cultivated areas. | |||

| ] in ] at the ]). The cloth was found in the sacred Ipot cave of ]. It is made from abacá.<ref name="ocampo">{{cite news |last1=Ocampo |first1=Ambeth R. |title=History and design in Death Blankets |url=https://opinion.inquirer.net/15599/history-and-design-in-death-blankets |access-date=2 June 2023 |work=Inquirer |date=19 October 2011}}</ref>]] | |||

| Today, Catanduanes has many other modern kinds of abacá which are more competitive. For many years, breeders from various research institutions have made the cultivated varieties of Catanduanes even more competitive in local and international markets. This results in the optimum production of the island which had a consistent highest production throughout the archipelago.<ref>{{Cite web |last=Flores |first=Helen |date=April 30, 2022 |title=Catanduanes declared Philippines abaca capital |url=https://www.philstar.com/nation/2022/04/30/2177709/catanduanes-declared-philippines-abaca-capital- |access-date=2024-06-02 |website=Philstar.com}}</ref> | |||

| === 16th century === | |||

| ], ]]] | |||

| Europeans first came into contact with Abacá fibre when ] landed in the Philippines in 1521, as the natives were already cultivating it and utilizing it in bulk for textiles.<ref name=wood/> Throughout the ], it was referred to as "''medriñaque''" cloth.{{sfn|Blair|1906}} | |||

| === 19th century === | |||

| By 1897, the Philippines were exporting almost 100,000 tons of abacá,<ref name="wor" /> and it was one of the three biggest cash crops, along with tobacco and sugar.<ref name="dolan">{{harvnb|Seekins|1993|p=11}}</ref> In fact, from 1850 through the end of the 19th century, sugar or abacá alternated with each other as the biggest export crop of the Philippines.<ref name="dolan" /> This 19th-century trade was predominantly with the ] and the making of ropes was done mainly in ], although in time rope-making shifted back to the Philippines.<ref name="dolan" /> | |||

| From 1898 to 1946, the ] following the ]. The ] claims the "colonial government found ways to prevent Filipinos from profiting off of the abaca crops, instead favoring the businesses of American expats and Japanese immigrants, as well as ensuring that the bulk of the abaca harvests were exported to the United States" for use in military initiatives.<ref name=":02">{{Cite web |title=A Manila Envelope: The Inspiration behind an Exhibition's Graphic Identity |url=https://www.guggenheim.org/articles/checklist/a-manila-envelope-the-inspiration-behind-an-exhibitions-graphic-identity |access-date=2023-10-27 |website=The Guggenheim Museums and Foundation |language=en-US}}</ref> | |||

| === 20th century === | |||

| In the early 1900s, a train running from ] to ] would transport Philippine abacá from the plantations to ] for export.<ref>{{cite web|last1=Tampos|first1=Nikki|title=What happened to Cebu's old train?|url=http://www.everythingcebu.com/lifestyle/what-happened-to-cebus-old-train/|website=www.everythingcebu.com|date=July 16, 2015|publisher=Everything Cebu|access-date=November 18, 2016}}</ref> The railway system was destroyed during World War II; the abaca continues to be transported to Cebu by road.<ref>{{cite web|last1=Palmera|first1=Erica Jean|title=The Sugbo railway|url=http://www.rafi.org.ph/news-highlights/sugbo-railway/|website=www.rafi.org.ph|publisher=RAFI|access-date=November 18, 2016|archive-url=https://web.archive.org/web/20160608113319/http://www.rafi.org.ph/news-highlights/sugbo-railway/|archive-date=June 8, 2016|url-status=dead}}</ref> | |||

| Outside the Philippines, abacá was first cultivated on a large scale in ] in 1925 under the ], who had observed its cultivation in the Philippines for ] since the nineteenth century, followed up by plantings in ] in 1929 sponsored by the ].<ref name="eb">{{harvnb|Hoiberg|2010|p=6}}</ref> It also was transplanted into ] and ].<ref name="wood" /> Commercial planting began in 1930 in ]; at the onset of ], the supply from the Philippines was eliminated by the ].<ref name="eb" /> | |||

| After the war, the ] started production in ], ], ], and ].<ref name="wood" /> | |||

| === 21st century === | |||

| Today, abacá is produced primarily in the Philippines and Ecuador.<ref>{{cite web|url=http://www.fao.org/economic/futurefibres/fibres/abaca0/en/|title=Future Fibres: Abaca|website=www.fao.org|language=en|access-date=February 16, 2017}}</ref> The Philippines produces between 85%<ref name="NIMBB" /> and 95%<ref name="wood" /> of the world's abacá, and the production employs 1.5 million people. Production has declined because of virus diseases.<ref name="NIMBB">{{harvnb|Anon|2013a}}</ref> | |||

| ==Cultivation== | |||

| The plant is normally grown in well-drained ]y soil, using ] planted at the start of the rainy season.<ref name="eb"/> In addition, new plants can be started by seeds.<ref name=van/> Growers harvest abacá fields every three to eight months after an initial growth period of 12–25 months.{{sfn|Bailey|1947}}<ref name="eb"/> Harvesting is done by removing the leaf-stems after flowering but before the fruit appears.{{sfn|Bailey|1947}} The plant loses productivity between 15 to 40 years.{{sfn|Bailey|1947|p=171}} The slopes of volcanoes provide a preferred growing environment.<ref name="Colliers">{{harvnb|Borneman|1997|p=4}}</ref> Harvesting generally includes several operations involving the leaf sheaths: | |||

| * tuxying (separation of primary and secondary sheath) | * tuxying (separation of primary and secondary sheath) | ||

| * stripping (getting the fibers) | * stripping (getting the fibers) | ||

| * drying (usually following tradition of sun-drying). |

* drying (usually following the tradition of sun-drying). | ||

| When the processing is complete, the bundles of fiber are pale and lustrous with a length of {{convert|6|-|12|ft|m}}.<ref name=van>{{harvnb|Considine|Considine|1983|p=1}}</ref><gallery mode="packed" heights="200"> | |||

| The fibers can then be spun into twines or cordage. | |||

| File:01-QWSTION-BANANATEX-ABACA-LEAVES-LAUSCHSICHT.jpg|'''1.''' Abacá plants have several stalks which can be harvested annually and regenerate fully within a year.<ref>{{Cite web|title=BANANATEX®|url=https://www.bananatex.info/responsibility_EN.html|access-date=2021-07-12|website=www.bananatex.info}}</ref> | |||

| File:06-QWSTION-BANANATEX-ABACA-HARVEST-LAUSCHSICHT.jpg|'''2.''' Abacá plants are harvested by "topping", cutting the leaves with a bamboo sickle, cutting or "tumbling" the stalks. The leaves are compost on the ground, creating a fertiliser. | |||

| File:12-QWSTION-BANANATEX-TUXYING-LAUSCHSICHT.jpg|'''3.''' The tuxy, the outer layer of the leaf sheath contains primary fibres is separated from the inner layers. | |||

| File:13-QWSTION-BANANATEX-TUXYING-2-LAUSCHSICHT.jpg|'''4.''' The inner layers contain the secondary fibres and pulpy material. | |||

| File:14-QWSTION-BANANATEX-STRIPPING-LAUSCHSICHT.jpg|'''5.'''The tuxies are separated by hand using a stripping knife at the harvesting site. | |||

| File:16-QWSTION-BANANATEX-STRIPPING-LAUSCHSICHT-2.jpg|'''6.''' The fibres are then "combed" to separate them. | |||

| File:20-QWSTION-BANANATEX-FIBERS-2-LAUSCHSICHT.jpg|'''7.''' The fibres are then air-dried and bundled together before being transported from forest to the trading warehouse of the farmers cooperative. | |||

| File:23-QWSTION-BANANATEX-ABACA-GRADES.jpg|'''8.''' There they are sorted by colour grades, with lighter coloured fibres being more expensive due to their rarity.<ref>{{Cite web|date=2020-04-27|title=Bananatex®, the World's First Waterproof Fabric Made From Banana Plants|url=https://globalshakers.com/bananatex-the-worlds-first-waterproof-fabric-made-from-banana-plants/|access-date=2021-07-12|website=Global Shakers|language=en-US}}</ref> | |||

| </gallery> | |||

| In Costa Rica, more modern harvest and drying techniques are being developed to accommodate the very high yields obtained there. | |||

| == Applications == | |||

| Abacá rope is very durable, flexible and resistant to ] (for this reason it is often used in ropes, hawsers, lines on ships and for things like ]s<ref name="eb"/> . It can also be used to make handcrafted products like bags, carpets, clothing, and furniture. The fibers can also be pulped and then processed into specialty paper such as tea bags, vacuum bags, currency paper, special paper, and more. Lupis is the finest quality of abaca. Sinamay is woven chiefly from abaca.<ref>"lupis", "sinamay" in Merriam-Webster's Unabrdiged Dictionary, third edition</ref> | |||

| According to the ], the Philippines provided 87.4% of the world's abacá in 2014, earning the Philippines US$111.33 million.<ref name="Malaya2015">{{cite news|title=PH biggest abaca exporter {{!}} Malaya Business Insight|url=http://www.malaya.com.ph/business-news/business/ph-biggest-abaca-exporter|work=Malaya Business Insight|date=June 15, 2015|access-date=June 14, 2016|archive-url=https://web.archive.org/web/20160809215438/http://www.malaya.com.ph/business-news/business/ph-biggest-abaca-exporter|archive-date=August 9, 2016|url-status=dead}}</ref> The demand is still greater than the supply.<ref name="Malaya2015" /> The remainder came from Ecuador (12.5%) and Costa Rica (0.1%).<ref name="Malaya2015" /> The ] in the Philippines produced 27,885 ]s of abacá in 2014, the largest of any ].<ref name="Malaya2015" /> | |||

| ==Scientific classification== | |||

| The abacá plant belongs to the ] family, ]; it resembles its closely related cousin plant, the '']''. Its scientific name is ''Musa textilis''. | |||

| The Philippine Rural Development Program (PRDP) and the Department of Agriculture reported that in 2009–2013, Bicol Region had a 39% share of Philippine abacá production of which an overwhelming 92% came from ]. Eastern Visayas, the second largest producer had 24% and the Davao Region, the third largest producer had 11% of the total production. Around 42 percent of the total abacá fiber shipments from the Philippines went to the United Kingdom in 2014, making it the top importer.<ref name="Malaya2015" /> Germany imported 37.1 percent abacá pulp from the Philippines, importing around 7,755 metric tons (MT).<ref name="Malaya2015" /> Sales of abacá cordage surged 20 percent in 2014 to a total of 5,093'' ''MT from 4,240'' ''MT, with the United States holding around 68 percent of the market.<ref name="Malaya2015" /> | |||

| ===Pathogens=== | |||

| Abacá is vulnerable to a number of pathogens, notably ], ],<ref name="NIMBB"/> and ].<ref name="abaca-strain-EPPO-GD">{{cite web | title=Sugarcane mosaic virus abaca mosaic strain (SCMVA0){{bracket|Overview}} | website=Global Database | publisher=EPPO (]) | date=February 4, 2001 | url=http://gd.eppo.int/taxon/SCMVA0 | access-date=September 4, 2021}}</ref> | |||

| == Uses == | |||

| ]]] | |||

| Due to its strength, it is a sought after product and is the strongest of the natural fibers.<ref name="wood" /> It is used by the paper industry for such specialty uses such as ], banknotes<ref>{{Cite web |title=A Primer on the New Generation Philippine Currency |url=http://www.bsp.gov.ph/downloads/Publications/FAQs/currencyprogram.pdf |archive-url=https://web.archive.org/web/20190529033050/http://www.bsp.gov.ph/downloads/Publications/FAQs/currencyprogram.pdf |archive-date=May 29, 2019 |access-date=July 12, 2019 |website=Bangko Sentral ng Pilipinas |page=7}}</ref> and decorative papers.<ref name="wood" /> It can be used to make handcrafts such as hats,<ref>{{cite web |title=All About Sinamay |url=http://www.torbandreiner.com/MillineryMaterials/sinamay |url-status=live |archive-url=https://web.archive.org/web/20200120063235/http://www.torbandreiner.com/MillineryMaterials/sinamay |archive-date=January 20, 2020 |publisher=Torb & Reiner}}</ref> bags, carpets, clothing and furniture. | |||

| Lupis is the finest quality of abacá.<ref name="bab1">{{harvnb|Gove|1976|p=1347}}</ref> Sinamay is woven chiefly from abacá.<ref name="bab2">{{harvnb|Gove|1976a|p=2122}}</ref> | |||

| ===Textiles=== | |||

| {{See also|Barong tagalog}} | |||

| ]'' cloth of the ] dreamweavers are made from abacá fibers]] | |||

| ] dreamweaver using a traditional loom]] | |||

| Abacá fibers were traditionally woven into sturdy textiles and clothing in the Philippines since pre-colonial times. Along with ], they were the main source of textile fibers used for clothing in the pre-colonial Philippines. Abacá cloth was often compared to ] in terms of texture and was a major trade commodity in the ] and the ].<ref name="Craig">{{cite book |last1=Craig |first1=Austin |last2=Benitez |first2=Conrado |title=Philippine Progress Prior to 1898: A Source Book of Philippine History to Supply a Fairer View of Filipino Participation and Supplement the Defective Spanish Accounts |date=1916 |publisher=Philippine Education Co., Inc. |location=Manila}}</ref><ref name="Ocampo">{{cite news |last1=Ocampo |first1=Keith R. |title=Demand rises for PH abaca as raw material for PPE |url=https://newsinfo.inquirer.net/1272482/demand-rises-for-ph-abaca-as-raw-material-for-ppe |access-date=30 May 2023 |newspaper=Philippine Daily Inquirer |date=10 May 2020}}</ref> There are multiple traditional types and names of abaca cloth among the different ]. Undyed plain abacá cloth, woven from fine fibers of abaca, is generally known as ''sinamáy'' in most of the islands. Abacá cloth with a more delicate texture is called ''tinampipi''. While especially fine lace-like abacá cloth is called ''nipis'' or ''lupis''. Fine abacá fibers may also be woven with '']'', ], or fine cotton to create a fabric called ''jusi''.<ref name="hendrickx"/> | |||

| Traditional abacá textiles were often dyed in various colors from various ]s. These include blue from ] (''tarum'', ''dagum'', ''tayum'', etc.); black from ] (''knalum'' or ''batulinao'') leaves; red from ] roots and '']''; yellow from ] (''kalawag'', ''kuning'', etc.); and so on. They were often woven into specific patterns, and further ornamented with embroidery, beadwork, and other decorations.<ref name="Palasi">{{cite web |last1=Palasi |first1=Kat |title=Philippine Natural Dyes: A Short Overview |url=https://www.habiphilippinetextilecouncil.com/blogs/what-we-do/philippine-natural-dyes-a-short-overview |website=HABI: The Philippine Textile Council |access-date=31 May 2023}}</ref><ref name="hendrickx"/> Most clothing made from abacá took the form of the ''baro'' (also ''barú'' or ''bayú'', literally "shirt" or "clothing"), a simple collar-less shirt or jacket with close-fitting long sleeves worn by both men and women in most ethnic groups in the ]. These were paired with wraparound sarong-like skirts (for both men and women), close-fitting pants, or loincloths ('']'').<ref name="hendrickx"/><ref name="Coo 2014">{{Cite thesis |last=Coo |first=Stéphanie Marie R. |title=Clothing and the Colonial Culture of Appearances in Nineteenth Century Spanish Philippines (1820–1896) |date=2014 |degree=PhD |publisher=Université Nice Sophia Antipolis |url=https://tel.archives-ouvertes.fr/tel-01126974/document}}</ref><ref name="Ramos 2016">{{Cite thesis |last=Ramos |first=Marlene Flores |title=The Filipina ''Bordadoras'' and the Emergence of Fine European-Style Embroidery Tradition in Colonial Philippines, 19th to early-20th Centuries |date=2016 |degree=MA |publisher=Mount Saint Vincent University |hdl=10587/1788 |hdl-access=free |s2cid=194439772}}</ref> | |||

| During the ], abacá cloth became known as '''medriñaque''' in ] (apparently derived from a native ] name). They were exported to other Spanish colonies since the 16th century. A ] of a native ] man in ] was recorded as being made of medriñaque as early as 1584. Abacá cloth also appear in English records, spelled variously as '''medrinacks''', '''medrianacks''', '''medrianackes''', and '''medrinacles''', among other names. They were used as ] for sails and for stiffening clothing like skirts, collars, and ]s.<ref name="hendrickx"/><ref name="Craig"/><ref name="Castro-Baker">{{cite book |last1=Castro-Baker |first1=Sandra |title=Textiles in the Philippine Landscape: A Lexicon and Historical Survey |date=2018 |publisher=Ateneo De Manila University Press |isbn=9789715508957}}</ref> | |||

| Philippine indigenous tribes still weave abacá-based textiles like '']'', made by the ] tribe of ], and ''dagmay'', made by the ] people.<ref>{{cite web |title=Philippine Basketry of the Luzon Cordillera {{pipe}} www.flysfo.cn |url=https://www.flysfo.com/museum/exhibitions/philippine-basketry-luzon-cordillera |url-status=dead |archive-url=https://web.archive.org/web/20170930085352/http://www.flysfo.com/museum/exhibitions/philippine-basketry-luzon-cordillera |archive-date=September 30, 2017 |access-date=June 17, 2019 |publisher=Flysfo.com |language=zh}}</ref> Abacá cloth is found in museum collections around the world, like the Boston Museum of Fine Arts and the Textile Museum of Canada.<ref name="acl"/> | |||

| The inner fibers are also used in the making of hats, including the "Manila hats", hammocks, matting, ], ropes, coarse twines, and types of canvas.<ref name="acl">{{cite web |title=Abaca cloth |url=http://www.mfa.org/collections/object/abaca-cloth-73450 |access-date=September 1, 2015}}</ref><ref>{{cite web |title=Textile Museum of Canada Collection and Exhibitions {{!}} Textile Museum of Canada Collection and Exhibitions |url=http://collections.textilemuseum.ca/index.cfm?page=collection.browse&sub=Yarn,_Fabric_and_Fabric_Finishing_Material&cat=ArtifactType&id=668 |access-date=September 1, 2015 |website=collections.textilemuseum.ca}}</ref> | |||

| === Industrial textile production === | |||

| ==== Processing ==== | |||

| <gallery mode="packed" heights="200"> | |||

| File:30-QWSTION-BANANATEX-FIBER-PULP-SHEETS-LAUSCHSICHT.jpg|alt=1. The raw fibres are tied with rope and shipped to Mindanao, Philippines, where they are boiled and pressed into cardboard like sheets which are then shipped to Taiwan.|'''1.''' The raw fibres are tied with rope and shipped to a factory, where they are boiled and pressed into cardboard like sheets.<ref>{{Cite web|title=BANANATEX®|url=https://www.bananatex.info/index.html#manufacturing|access-date=2021-07-12|website=www.bananatex.info}}</ref> | |||

| File:31-QWSTION-BANANATEX-PAPER-MAKING.jpg|'''2.''' The abacá fibre sheets are then soaked in water. | |||

| File:32-QWSTION-BANANATEX-ABACA-PAPER-LAUSCHSICHT.jpg|'''3.''' They are then made into paper which are then cut into strips. | |||

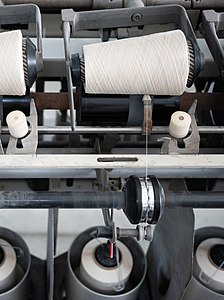

| File:34-QWSTION-BANANATEX-YARN-SPINNING.jpg|'''4.''' The paper strips are then spun into yarn. | |||

| </gallery> | |||

| ===== Dyeing and weaving ===== | |||

| <gallery mode="packed" heights="200"> | |||

| File:36-1-QWSTION-BANANATEX-YARN-DYEING-2.jpg|alt=1. The natural white yarn is sent to Qwstion's dyeing and weaving partner in Tainan, Taiwan. They colour the yarn using the yarn dyeing method which is more sustainable than the roll dyeing alternative and certified OekoTex® Standard 100, the highest standard.|'''1.''' The natural white yarn is then coloured using the yarn dyeing method which is more sustainable than the roll dyeing alternative.<ref>{{Cite web|title=Eliminating silo thinking and the word 'waste', plus a tip from Jimi Hendrix|url=https://www.innovationintextiles.com/interviews/|access-date=2021-07-12|website=www.innovationintextiles.com}}</ref> | |||

| File:40-QWSTION-BANANATEX-WARPING-LAUSCHSICHT.jpg|'''2.''' The warp yarns are then prepared for weaving. | |||

| File:38-QWSTION-BANANATEX-WEAVING-3-LAUSCHSICHT.jpg|'''3.''' The yarn is then woven at extra high density. | |||

| File:48-QWSTION-BANANATEX-LOOM-LAUSCHSICHT.jpg|Weaving looms processing the fabric. | |||

| File:49-QWSTION-BANANATEX-FABRIC.jpg|'''4.''' The finished Manila hemp fabric, a natural beeswax coating is added to make the fabric waterproof. This particular fabric is manufactured by the Swiss company QWSTION. | |||

| </gallery> | |||

| === Manila rope === | |||

| {{see also|Fiber rope}} | |||

| ] | |||

| Manila rope is a type of ] made from manila hemp. Manila rope is very durable, flexible, and resistant to ] damage, allowing its use in rope, ]s, ships' lines, and ]s.<ref name="eb" /> A {{convert|1|in|cm}} rope can require {{convert|4|MT|lb}} to break.<ref name="Colliers" /> Manilla rope is still the only material specified for lifeboat falls (the ropes with which a ship's lifeboat is lowered) in the United Kingdom.<ref>{{cite web |title=NATURAL & SYNTHETIC FIBRE CORDAGE FOR LIFE SAVING APPLIANCES |url=https://assets.publishing.service.gov.uk/media/5fbce3d58fa8f559e77576e0/MGN_106__M+F_.pdf |publisher=Marine and Coastguard Agency |access-date=9 July 2024}}</ref> | |||

| Manila ropes shrink when they become wet. This effect can be advantageous under certain circumstances, but if it is not a wanted feature, it should be well taken into account. Since shrinkage is more pronounced the first time the rope becomes wet, new rope is usually immersed into water and put to dry before use so that the shrinkage is less than it would be if the rope had never been wet. A major disadvantage in this shrinkage is that many knots made with manila rope became harder and more difficult to untie when wet, thus becoming subject of increased stress. Manila rope will rot after a period of time when exposed to saltwater. | |||

| Manila hemp rope was previously the favoured variety of rope used for executions by hanging, both in the U.K. and USA. Usually 3/4 to 1 inch diameter, boiled prior to use to take out any overelasticity. It was also used in the 19th century as whaling line.<ref name="hm"> ], 1851, ]</ref> Abacá fiber was once used primarily for rope, but this application is now of minor significance. | |||

| ==See also== | |||

| *'']'' (Japanese banana), banana species also used as a traditional source of fiber in Okinawa, Japan | |||

| *], similar traditional fiber from Okinawa, Japan | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| * ] | |||

| ==Notes== | |||

| {{Reflist|group=nb}} | |||

| ==Footnotes== | |||

| {{Reflist}} | |||

| ==References== | ==References== | ||

| * {{cite book |title=The Philippine Islands, 1493-1898 Vol. 15 |last=Blair |first=Emma |year=1906 |publisher=Arthur H. Clark Company |url=http://www.gutenberg.org/cache/epub/7001/pg7001-images.html}} | |||

| {{reflist}} | |||

| * {{GRIN | access-date=June 10, 2014}} | |||

| *The ] encyclopedia set, 1988. | |||

| * {{cite web|author=Anon |year=2013 |url=http://www.theplantlist.org/tpl1.1/record/kew-255018 |title=''Musa textilis'' Née |website=The Plant List |access-date=June 4, 2014 |archive-date=August 5, 2017 |archive-url=https://web.archive.org/web/20170805231405/http://www.theplantlist.org/tpl1.1/record/kew-255018 |url-status=live }} | |||

| * {{cite web |author=Anon |url=http://www.nimbb.upd.edu.ph/?page_id=103 |title=(Research) Plant Molecular Biology and Plant Virology |website=National Institute of Molecular Biology and Biotechnology |year=2013a |archive-date=December 3, 2013 |access-date=June 4, 2014 |archive-url=https://web.archive.org/web/20131203005532/http://www.nimbb.upd.edu.ph/?page_id=103 |url-status=dead }} | |||

| * {{cite encyclopedia | editor-last = Bailey | editor-first = L. H. | encyclopedia = The Standard Cyclopedia of Horticulture | title = Abacá | publisher = The Macmillan Company | location = New York, NY | year = 1947 | orig-year = 1900 | volume = I: A-E }} | |||

| * {{cite encyclopedia | last1 = Borneman | first1 = John A. Jr.| editor-last = Johnston | editor-first = Bernard | encyclopedia = Collier's Encyclopedia | title = Abaca | edition = 1st | year = 1997 | publisher = P. F. Collier | volume = I: A to Ameland | location = New York, NY }} | |||

| * {{cite encyclopedia | editor1-last = Considine | editor1-first = Douglas M. | editor2-last = Considine | editor2-first = Glenn D. | encyclopedia = Van Nostrand's Scientific Encyclopedia | edition = 6th | volume = I: A-H | publisher = Van Nostrand Reinhold Company | location = New York, NY | isbn = 0-442-25164-5 | title = Abaca | year = 1983 }} | |||

| * {{cite encyclopedia | editor-last = Gove | editor-first = Philip Babcock | encyclopedia = Webster's Third New International Dictionary | edition = 3rd | year = 1976 | publisher = G. & C. Merriam Company | location = Springfield, MA | isbn = 0-87779-101-5 | title = Lupis }} | |||

| * {{cite encyclopedia | editor-last = Gove | editor-first = Philip Babcock | encyclopedia = Webster's Third New International Dictionary | edition = 3rd | year = 1976a | publisher = G. & C. Merriam Company | location = Springfield, MA | isbn = 0-87779-101-5 | title = Sinamay }} | |||

| * {{cite encyclopedia | editor-last = Hoiberg | editor-first = Dale H. | encyclopedia = ] | year = 2010 | volume = 1: A - ak Bayes | edition = 15th | publisher = Encyclopædia Britannica Inc. | location = Chicago, Illinois | isbn = 978-0-85229-961-6 | title = Sbaca }} | |||

| * {{cite book | last1 = Ploetz | first1 = Randy C. | last2 = Kepler | first2 = Angela Kay | last3 = Daniells | first3 = Jeff | last4 = Nelson | first4 = Scot C. | editor-last = Elevitch | editor-first = C. R. | year = 2007 | chapter = Banana and Plantain: An Overview with Emphasis on Pacific Island Cultivars | title = Species Profiles for Pacific Island Agroforestry | location = Hōlualoa, HI | publisher = Permanent Agriculture Resources (PAR) | url = http://agroforestry.net/tti/Banana-plantain-overview.pdf | access-date = June 4, 2014 | archive-date = January 1, 2016 | url-status = live | archive-url = https://web.archive.org/web/20160101232525/http://agroforestry.net/images/pdfs/Banana-plantain-overview.pdf | name-list-style = amp | website = www.traditionaltree.org | pages = 1–27 }} | |||

| * {{cite book | last = Seekins | first = Donald M. | editor-last = Dolan | editor-first = Ronald E. | title = Philippines: A Country Study | year = 1993 | isbn = 0-8444-0748-8 | publisher = United States Government Printing Office | location = Washington, DC | url-access = registration | url = https://archive.org/details/philippinescount00dola }} | |||

| * {{cite journal | last1 = Wong | first1 = Carol | last2 = Kiew | first2 = Ruth | last3 = Argent | first3 = George | last4 = Set | first4 = Ohn | last5 = Lee | first5 = Sing Kong | last6 = Gan | first6 = Yik Yuen | year = 2002 | title = Assessment of the Validity of the Sections in ''Musa'' (Musaceae) using ALFP | journal = Annals of Botany | volume = 90 | issue = 2 | pages = 231–238 | doi = 10.1093/aob/mcf170 | name-list-style = amp | pmc = 4240415 | pmid=12197520}} | |||

| * {{cite book | last1 = Wood | first1 = Frances A. | last2 = Roberts | first2 = George A. F. | editor1-last = Prance | editor1-first = Ghillean | editor2-last = Nesbitt | editor2-first = Mark | title = The Cultural History of Plants | publisher = Routledge | location = New York, NY | isbn = 0-415-92746-3 | year = 2005 }} | |||

| * {{cite book | last = Worcester | first = Dean C. | title = The Philippine Islands and Their People | url = https://archive.org/details/philippineislan00worcgoog | publisher = The Macmillan Company | location = New York, NY | year = 1899 | orig-year = 1898 }} | |||

| *Yllano, O. B., Diaz, M. G. Q., Lalusin, A. G., Laurena, A. C., & Tecson-Mendoza, E. M. (2020). Genetic Analyses of Abaca (Musa textilis Née) Germplasm from its Primary Center of Origin, the Philippines, Using Simple Sequence Repeat (SSR) Markers. ''Philippine Agricultural Scientist'', ''103''(4). | |||

| ==External links== | ==External links== | ||

| {{Commons category|Musa textilis}} | |||

| {{Wikisource1911Enc|Abaca}} | |||

| {{EB1911 poster|Abaca}} | |||

| * | |||

| {{Wikispecies|Musa textilis}} | |||

| * | |||

| *The ] encyclopedia set, 1988. | |||

| * A comprehensive pamphlet about Philippine abaca presented 1915 Panama Pacific International Exposition held in San Francisco. Online publication uploaded in | |||

| *See ] 2009 | |||

| *{{cite journal | last1 = Christenhusz | first1 = M.J.M. | year = 2009 | title = Typification of ornamental plants: ''Musa textilis'' (Musaceae) | journal = ] | volume = 2 | pages = 53–54 | doi=10.11646/phytotaxa.2.1.10}} | |||

| * A comprehensive pamphlet about Philippine abacá presented 1915 Panama Pacific International Exposition held in San Francisco. Online publication uploaded in | |||

| {{Fibers}} | |||

| {{Textile}} | |||

| {{Taxonbar|from=Q161097}} | |||

| {{Authority control}} | |||

| {{DEFAULTSORT:Abaca}} | |||

| ] | |||

| ] | |||

| ] | ] | ||

| ] | ] | ||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

| ] | |||

Latest revision as of 21:13, 11 November 2024

Species of plant "Abacas" redirects here. Not to be confused with Abacus.

| Abacá Musa textilis | |

|---|---|

| |

| At the United States Botanic Garden | |

| Scientific classification | |

| Kingdom: | Plantae |

| Clade: | Tracheophytes |

| Clade: | Angiosperms |

| Clade: | Monocots |

| Clade: | Commelinids |

| Order: | Zingiberales |

| Family: | Musaceae |

| Genus: | Musa |

| Section: | Musa sect. Callimusa |

| Species: | M. textilis |

| Binomial name | |

| Musa textilis Née | |

| Synonyms | |

| List | |

Abacá (/ɑːbəˈkɑː/ ah-bə-KAH; Filipino: abaka [ɐbɐˈka]), also known as Manila hemp, is a species of banana, Musa textilis, endemic to the Philippines. The plant grows to 13–22 feet (4.0–6.7 m), and averages about 12 feet (3.7 m). The plant has great economic importance, being harvested for its fiber extracted from the leaf-stems.

The lustrous fiber is traditionally hand-loomed into various indigenous textiles (abaca cloth or medriñaque) in the Philippines. They are still featured prominently as the traditional material of the barong tagalog, the national male attire of the Philippines, as well as in sheer lace-like fabrics called nipis used in various clothing components. Native abaca textiles also survive into the modern era among various ethnic groups, like the t'nalak of the T'boli people and the dagmay of the Bagobo people. Abaca is also used in traditional Philippine millinery, as well as for bags, shawls, and other decorative items. The hatmaking straw made from Manila hemp is called tagal or tagal straw.

The fiber is also exceptionally strong, stronger than hemp and naturally salt-resistant, making it ideal for making twines and ropes (especially for maritime shipping). It became a major trade commodity in the colonial era for this reason. The abaca industry declined sharply in the mid-20th century when abaca plantations were decimated by World War II and plant diseases, as well as the invention of nylon in the 1930s. Today, abaca is mostly used in a variety of specialized paper products including tea bags, filter paper and banknotes. Manila envelopes and Manila paper derive their name from this fiber.

Abaca is classified as a hard fiber, along with coir, henequin and sisal. Abaca is grown as a commercial crop in the Philippines, Ecuador, Costa Rica.

Description

The abacá plant is stoloniferous, meaning that the plant produces runners or shoots along the ground that then root at each segment. Cutting and transplanting rooted runners is the primary technique for creating new plants, since seed growth is substantially slower. Abacá has a "false trunk" or pseudostem about 6–15 inches (15–38 cm) in diameter. The leaf stalks (petioles) are expanded at the base to form sheaths that are tightly wrapped together to form the pseudostem. There are from 12 to 25 leaves, dark green on the top and pale green on the underside, sometimes with large brown patches. They are oblong in shape with a deltoid base. They grow in succession. The petioles grow to at least 1 foot (30 cm) in length.

When the plant is mature, the flower stalk grows up inside the pseudostem. The male flower has five petals, each about 1.5 inches (3.8 cm) long. The leaf sheaths contain the valuable fiber. After harvesting, the coarse fibers range in length from 6–12 feet (180–370 cm) long. They are composed primarily of cellulose, lignin, and pectin.

The fruit, which is inedible and is rarely seen as harvesting occurs before the plant fruits, grows to about 2–3 inches (5.1–7.6 cm) in length and 1 inch (2.5 cm) in diameter. It has black turbinate seeds that are 0.167 inches (0.42 cm) in diameter.

Systematics

The abacá plant belongs to the banana family, Musaceae; it resembles the closely related wild seeded bananas, Musa acuminata and Musa balbisiana. Its scientific name is Musa textilis. Within the genus Musa, it is placed in section Callimusa (now including the former section Australimusa), members of which have a diploid chromosome number of 2n = 20.

Genetic diversity

The Philippines, especially the Bicol region in Luzon, has the most abaca genotypes and cultivars. Genetic analysis using simple sequence repeats (SSR) markers revealed that the Philippines' abaca germplasm is genetically diverse. Abaca genotypes in Luzon had higher genetic diversity than Visayas and Mindanao. Ninety-five (95) percent was attributed to molecular variance within the population, and only 5% of the molecular variance to variation among populations. Genetic analysis by Unweighted Pair Group Method with Arithmetic Mean (UPGMA) revealed several clusters irrespective of geographical origin.

History

Before synthetic textiles came into use, M. textilis was a major source of high quality fiber: soft, silky and fine. Ancestors of the modern abacá are thought to have originated from the eastern Philippines, where there is significant rainfall throughout the year. Wild varieties of abacá can still be found in the interior forests of the island province of Catanduanes, away from cultivated areas.

Today, Catanduanes has many other modern kinds of abacá which are more competitive. For many years, breeders from various research institutions have made the cultivated varieties of Catanduanes even more competitive in local and international markets. This results in the optimum production of the island which had a consistent highest production throughout the archipelago.

16th century

Europeans first came into contact with Abacá fibre when Ferdinand Magellan landed in the Philippines in 1521, as the natives were already cultivating it and utilizing it in bulk for textiles. Throughout the Spanish colonial era, it was referred to as "medriñaque" cloth.

19th century

By 1897, the Philippines were exporting almost 100,000 tons of abacá, and it was one of the three biggest cash crops, along with tobacco and sugar. In fact, from 1850 through the end of the 19th century, sugar or abacá alternated with each other as the biggest export crop of the Philippines. This 19th-century trade was predominantly with the United States and the making of ropes was done mainly in New England, although in time rope-making shifted back to the Philippines.

From 1898 to 1946, the United States colonized the Philippines following the Spanish-American War. The Guggenheim claims the "colonial government found ways to prevent Filipinos from profiting off of the abaca crops, instead favoring the businesses of American expats and Japanese immigrants, as well as ensuring that the bulk of the abaca harvests were exported to the United States" for use in military initiatives.

20th century

In the early 1900s, a train running from Danao to Argao would transport Philippine abacá from the plantations to Cebu City for export. The railway system was destroyed during World War II; the abaca continues to be transported to Cebu by road.

Outside the Philippines, abacá was first cultivated on a large scale in Sumatra in 1925 under the Dutch, who had observed its cultivation in the Philippines for cordage since the nineteenth century, followed up by plantings in Central America in 1929 sponsored by the U.S. Department of Agriculture. It also was transplanted into India and Guam. Commercial planting began in 1930 in British North Borneo; at the onset of World War II, the supply from the Philippines was eliminated by the Empire of Japan.

After the war, the U.S. Department of Agriculture started production in Panama, Costa Rica, Honduras, and Guatemala.

21st century

Today, abacá is produced primarily in the Philippines and Ecuador. The Philippines produces between 85% and 95% of the world's abacá, and the production employs 1.5 million people. Production has declined because of virus diseases.

Cultivation

The plant is normally grown in well-drained loamy soil, using rhizomes planted at the start of the rainy season. In addition, new plants can be started by seeds. Growers harvest abacá fields every three to eight months after an initial growth period of 12–25 months. Harvesting is done by removing the leaf-stems after flowering but before the fruit appears. The plant loses productivity between 15 to 40 years. The slopes of volcanoes provide a preferred growing environment. Harvesting generally includes several operations involving the leaf sheaths:

- tuxying (separation of primary and secondary sheath)

- stripping (getting the fibers)

- drying (usually following the tradition of sun-drying).

When the processing is complete, the bundles of fiber are pale and lustrous with a length of 6–12 feet (1.8–3.7 m).

-

1. Abacá plants have several stalks which can be harvested annually and regenerate fully within a year.

1. Abacá plants have several stalks which can be harvested annually and regenerate fully within a year.

-

2. Abacá plants are harvested by "topping", cutting the leaves with a bamboo sickle, cutting or "tumbling" the stalks. The leaves are compost on the ground, creating a fertiliser.

2. Abacá plants are harvested by "topping", cutting the leaves with a bamboo sickle, cutting or "tumbling" the stalks. The leaves are compost on the ground, creating a fertiliser.

-

3. The tuxy, the outer layer of the leaf sheath contains primary fibres is separated from the inner layers.

3. The tuxy, the outer layer of the leaf sheath contains primary fibres is separated from the inner layers.

-

4. The inner layers contain the secondary fibres and pulpy material.

4. The inner layers contain the secondary fibres and pulpy material.

-

5.The tuxies are separated by hand using a stripping knife at the harvesting site.

5.The tuxies are separated by hand using a stripping knife at the harvesting site.

-

6. The fibres are then "combed" to separate them.

6. The fibres are then "combed" to separate them.

-

7. The fibres are then air-dried and bundled together before being transported from forest to the trading warehouse of the farmers cooperative.

7. The fibres are then air-dried and bundled together before being transported from forest to the trading warehouse of the farmers cooperative.

-

8. There they are sorted by colour grades, with lighter coloured fibres being more expensive due to their rarity.

8. There they are sorted by colour grades, with lighter coloured fibres being more expensive due to their rarity.

In Costa Rica, more modern harvest and drying techniques are being developed to accommodate the very high yields obtained there.

According to the Philippine Fiber Industry Development Authority, the Philippines provided 87.4% of the world's abacá in 2014, earning the Philippines US$111.33 million. The demand is still greater than the supply. The remainder came from Ecuador (12.5%) and Costa Rica (0.1%). The Bicol region in the Philippines produced 27,885 metric tons of abacá in 2014, the largest of any Philippine region.

The Philippine Rural Development Program (PRDP) and the Department of Agriculture reported that in 2009–2013, Bicol Region had a 39% share of Philippine abacá production of which an overwhelming 92% came from Catanduanes Island. Eastern Visayas, the second largest producer had 24% and the Davao Region, the third largest producer had 11% of the total production. Around 42 percent of the total abacá fiber shipments from the Philippines went to the United Kingdom in 2014, making it the top importer. Germany imported 37.1 percent abacá pulp from the Philippines, importing around 7,755 metric tons (MT). Sales of abacá cordage surged 20 percent in 2014 to a total of 5,093 MT from 4,240 MT, with the United States holding around 68 percent of the market.

Pathogens

Abacá is vulnerable to a number of pathogens, notably abaca bunchy top virus, abaca bract mosaic virus, and abaca mosaic virus.

Uses

Due to its strength, it is a sought after product and is the strongest of the natural fibers. It is used by the paper industry for such specialty uses such as tea bags, banknotes and decorative papers. It can be used to make handcrafts such as hats, bags, carpets, clothing and furniture.

Lupis is the finest quality of abacá. Sinamay is woven chiefly from abacá.

Textiles

See also: Barong tagalog

Abacá fibers were traditionally woven into sturdy textiles and clothing in the Philippines since pre-colonial times. Along with cotton, they were the main source of textile fibers used for clothing in the pre-colonial Philippines. Abacá cloth was often compared to calico in terms of texture and was a major trade commodity in the pre-colonial maritime trade and the Spanish colonial era. There are multiple traditional types and names of abaca cloth among the different ethnic groups of the Philippines. Undyed plain abacá cloth, woven from fine fibers of abaca, is generally known as sinamáy in most of the islands. Abacá cloth with a more delicate texture is called tinampipi. While especially fine lace-like abacá cloth is called nipis or lupis. Fine abacá fibers may also be woven with piña, silk, or fine cotton to create a fabric called jusi.

Traditional abacá textiles were often dyed in various colors from various natural dyes. These include blue from indigo (tarum, dagum, tayum, etc.); black from ebony (knalum or batulinao) leaves; red from noni roots and sapang; yellow from turmeric (kalawag, kuning, etc.); and so on. They were often woven into specific patterns, and further ornamented with embroidery, beadwork, and other decorations. Most clothing made from abacá took the form of the baro (also barú or bayú, literally "shirt" or "clothing"), a simple collar-less shirt or jacket with close-fitting long sleeves worn by both men and women in most ethnic groups in the pre-colonial Philippines. These were paired with wraparound sarong-like skirts (for both men and women), close-fitting pants, or loincloths (bahag).

During the Spanish colonial era, abacá cloth became known as medriñaque in Spanish (apparently derived from a native Cebuano name). They were exported to other Spanish colonies since the 16th century. A waistcoat of a native Quechua man in Peru was recorded as being made of medriñaque as early as 1584. Abacá cloth also appear in English records, spelled variously as medrinacks, medrianacks, medrianackes, and medrinacles, among other names. They were used as canvas for sails and for stiffening clothing like skirts, collars, and doublets.

Philippine indigenous tribes still weave abacá-based textiles like t'nalak, made by the Tiboli tribe of South Cotabato, and dagmay, made by the Bagobo people. Abacá cloth is found in museum collections around the world, like the Boston Museum of Fine Arts and the Textile Museum of Canada.

The inner fibers are also used in the making of hats, including the "Manila hats", hammocks, matting, cordage, ropes, coarse twines, and types of canvas.

Industrial textile production

Processing

-

1. The raw fibres are tied with rope and shipped to a factory, where they are boiled and pressed into cardboard like sheets.

1. The raw fibres are tied with rope and shipped to a factory, where they are boiled and pressed into cardboard like sheets.

-

2. The abacá fibre sheets are then soaked in water.

2. The abacá fibre sheets are then soaked in water.

-

3. They are then made into paper which are then cut into strips.

3. They are then made into paper which are then cut into strips.

-

4. The paper strips are then spun into yarn.

4. The paper strips are then spun into yarn.

Dyeing and weaving

-

1. The natural white yarn is then coloured using the yarn dyeing method which is more sustainable than the roll dyeing alternative.

1. The natural white yarn is then coloured using the yarn dyeing method which is more sustainable than the roll dyeing alternative.

-

2. The warp yarns are then prepared for weaving.

2. The warp yarns are then prepared for weaving.

-

3. The yarn is then woven at extra high density.

3. The yarn is then woven at extra high density.

-

Weaving looms processing the fabric.

Weaving looms processing the fabric.

-

4. The finished Manila hemp fabric, a natural beeswax coating is added to make the fabric waterproof. This particular fabric is manufactured by the Swiss company QWSTION.

4. The finished Manila hemp fabric, a natural beeswax coating is added to make the fabric waterproof. This particular fabric is manufactured by the Swiss company QWSTION.

Manila rope

See also: Fiber rope

Manila rope is a type of rope made from manila hemp. Manila rope is very durable, flexible, and resistant to salt water damage, allowing its use in rope, hawsers, ships' lines, and fishing nets. A 1 inch (2.5 cm) rope can require 4 metric tons (8,800 lb) to break. Manilla rope is still the only material specified for lifeboat falls (the ropes with which a ship's lifeboat is lowered) in the United Kingdom.

Manila ropes shrink when they become wet. This effect can be advantageous under certain circumstances, but if it is not a wanted feature, it should be well taken into account. Since shrinkage is more pronounced the first time the rope becomes wet, new rope is usually immersed into water and put to dry before use so that the shrinkage is less than it would be if the rope had never been wet. A major disadvantage in this shrinkage is that many knots made with manila rope became harder and more difficult to untie when wet, thus becoming subject of increased stress. Manila rope will rot after a period of time when exposed to saltwater.

Manila hemp rope was previously the favoured variety of rope used for executions by hanging, both in the U.K. and USA. Usually 3/4 to 1 inch diameter, boiled prior to use to take out any overelasticity. It was also used in the 19th century as whaling line. Abacá fiber was once used primarily for rope, but this application is now of minor significance.

See also

- Musa basjoo (Japanese banana), banana species also used as a traditional source of fiber in Okinawa, Japan

- Kijōka-bashōfu, similar traditional fiber from Okinawa, Japan

- Piña

- T'nalak

- Malong

- Tapis

- Inabel

- Batik

- Yakan people

- Fiber crop

- International Year of Natural Fibres

- Natural fiber

- Manila folder

- Domesticated plants and animals of Austronesia

Notes

- A plant grown from a shoot takes three years to maturity; while a plant grown from a seed takes four years to maturity.

Footnotes

- ^ Bailey 1947.

- Bailey 1947, p. 2078.

- Anon 2013

- ^ H. T. Edwards; B. E. Brewer; George E. Nesom; Otis Warren Barrett; William Scrugham Lyon & Murad M. Saleeby (1904). "Abacá (manila hemp)". Farmers' Bulletin. Bureau of Agriculture. Republic of the Philippines.

- "Musa textilis". Germplasm Resources Information Network. Agricultural Research Service, United States Department of Agriculture. Retrieved June 5, 2014.

- ^ Katrien Hendrickx (1904). "The Origins of Banana-fibre Cloth in the Ryukyus, Japan". Farmers' Bulletin. Studia anthropologica. 11. Leuven University Press: 170. ISBN 978-90-5867-614-6.

- Dreher, Denise (1981). From the neck up : an illustrated guide to hatmaking (1st ed.). Minneapolis, Minn.: Madhatter. ISBN 9780941082006.

- Ginsburg, Madeleine (1990). The hat: trends and traditions (1st U.S. ed.). Hauppauge, N.Y.: Barron's. ISBN 9780812061987.

Tagal.

- "Manila hemp". Transport Information Service, Gesamtverband der Deutschen Versicherungswirtschaft e.V. Retrieved May 15, 2011.

- ^ Worcester 1899, p. 506

- ^ Wood & Roberts 2005, p. 301

- Wong et al. 2002, p. 234

- ^ Yllano, O. B.; Diaz, M. G. Q.; Lalusin, A. G.; Laurena, A. C.; Tecson-Mendoza, E. M. (2020). "Genetic Analyses of Abaca (Musa textilis Née) Germplasm from its Primary Center of Origin, the Philippines, Using Simple Sequence Repeat (SSR) Markers – The Philippine Agricultural Scientist". Retrieved February 16, 2021.

- Ploetz et al. 2007, p. 4

- Ocampo, Ambeth R. (October 19, 2011). "History and design in Death Blankets". Inquirer. Retrieved June 2, 2023.

- Flores, Helen (April 30, 2022). "Catanduanes declared Philippines abaca capital". Philstar.com. Retrieved June 2, 2024.

- Blair 1906.

- ^ Seekins 1993, p. 11

- "A Manila Envelope: The Inspiration behind an Exhibition's Graphic Identity". The Guggenheim Museums and Foundation. Retrieved October 27, 2023.

- Tampos, Nikki (July 16, 2015). "What happened to Cebu's old train?". www.everythingcebu.com. Everything Cebu. Retrieved November 18, 2016.

- Palmera, Erica Jean. "The Sugbo railway". www.rafi.org.ph. RAFI. Archived from the original on June 8, 2016. Retrieved November 18, 2016.

- ^ Hoiberg 2010, p. 6

- "Future Fibres: Abaca". www.fao.org. Retrieved February 16, 2017.

- ^ Anon 2013a

- ^ Considine & Considine 1983, p. 1

- Bailey 1947, p. 171.

- ^ Borneman 1997, p. 4

- "BANANATEX®". www.bananatex.info. Retrieved July 12, 2021.

- "Bananatex®, the World's First Waterproof Fabric Made From Banana Plants". Global Shakers. April 27, 2020. Retrieved July 12, 2021.

- ^ "PH biggest abaca exporter | Malaya Business Insight". Malaya Business Insight. June 15, 2015. Archived from the original on August 9, 2016. Retrieved June 14, 2016.

- "Sugarcane mosaic virus abaca mosaic strain (SCMVA0)[Overview]". Global Database. EPPO (European and Mediterranean Plant Protection Organization). February 4, 2001. Retrieved September 4, 2021.

- "A Primer on the New Generation Philippine Currency" (PDF). Bangko Sentral ng Pilipinas. p. 7. Archived from the original (PDF) on May 29, 2019. Retrieved July 12, 2019.

- "All About Sinamay". Torb & Reiner. Archived from the original on January 20, 2020.

- Gove 1976, p. 1347

- Gove 1976a, p. 2122

- ^ Craig, Austin; Benitez, Conrado (1916). Philippine Progress Prior to 1898: A Source Book of Philippine History to Supply a Fairer View of Filipino Participation and Supplement the Defective Spanish Accounts. Manila: Philippine Education Co., Inc.

- Ocampo, Keith R. (May 10, 2020). "Demand rises for PH abaca as raw material for PPE". Philippine Daily Inquirer. Retrieved May 30, 2023.

- Palasi, Kat. "Philippine Natural Dyes: A Short Overview". HABI: The Philippine Textile Council. Retrieved May 31, 2023.

- Coo, Stéphanie Marie R. (2014). Clothing and the Colonial Culture of Appearances in Nineteenth Century Spanish Philippines (1820–1896) (PhD thesis). Université Nice Sophia Antipolis.

- Ramos, Marlene Flores (2016). The Filipina Bordadoras and the Emergence of Fine European-Style Embroidery Tradition in Colonial Philippines, 19th to early-20th Centuries (MA thesis). Mount Saint Vincent University. hdl:10587/1788. S2CID 194439772.

- Castro-Baker, Sandra (2018). Textiles in the Philippine Landscape: A Lexicon and Historical Survey. Ateneo De Manila University Press. ISBN 9789715508957.

- "Philippine Basketry of the Luzon Cordillera | www.flysfo.cn" (in Chinese). Flysfo.com. Archived from the original on September 30, 2017. Retrieved June 17, 2019.

- ^ "Abaca cloth". Retrieved September 1, 2015.

- "Textile Museum of Canada Collection and Exhibitions | Textile Museum of Canada Collection and Exhibitions". collections.textilemuseum.ca. Retrieved September 1, 2015.

- "BANANATEX®". www.bananatex.info. Retrieved July 12, 2021.

- "Eliminating silo thinking and the word 'waste', plus a tip from Jimi Hendrix". www.innovationintextiles.com. Retrieved July 12, 2021.

- "NATURAL & SYNTHETIC FIBRE CORDAGE FOR LIFE SAVING APPLIANCES" (PDF). Marine and Coastguard Agency. Retrieved July 9, 2024.

- Moby-Dick, 1851, Herman Melville

References

- Blair, Emma (1906). The Philippine Islands, 1493-1898 Vol. 15. Arthur H. Clark Company.

- "Musa textilis". Germplasm Resources Information Network. Agricultural Research Service, United States Department of Agriculture. Retrieved June 10, 2014.

- Anon (2013). "Musa textilis Née". The Plant List. Archived from the original on August 5, 2017. Retrieved June 4, 2014.

- Anon (2013a). "(Research) Plant Molecular Biology and Plant Virology". National Institute of Molecular Biology and Biotechnology. Archived from the original on December 3, 2013. Retrieved June 4, 2014.

- Bailey, L. H., ed. (1947) . "Abacá". The Standard Cyclopedia of Horticulture. Vol. I: A-E. New York, NY: The Macmillan Company.

- Borneman, John A. Jr. (1997). "Abaca". In Johnston, Bernard (ed.). Collier's Encyclopedia. Vol. I: A to Ameland (1st ed.). New York, NY: P. F. Collier.

- Considine, Douglas M.; Considine, Glenn D., eds. (1983). "Abaca". Van Nostrand's Scientific Encyclopedia. Vol. I: A-H (6th ed.). New York, NY: Van Nostrand Reinhold Company. ISBN 0-442-25164-5.

- Gove, Philip Babcock, ed. (1976). "Lupis". Webster's Third New International Dictionary (3rd ed.). Springfield, MA: G. & C. Merriam Company. ISBN 0-87779-101-5.

- Gove, Philip Babcock, ed. (1976a). "Sinamay". Webster's Third New International Dictionary (3rd ed.). Springfield, MA: G. & C. Merriam Company. ISBN 0-87779-101-5.

- Hoiberg, Dale H., ed. (2010). "Sbaca". Encyclopædia Britannica. Vol. 1: A - ak Bayes (15th ed.). Chicago, Illinois: Encyclopædia Britannica Inc. ISBN 978-0-85229-961-6.

- Ploetz, Randy C.; Kepler, Angela Kay; Daniells, Jeff & Nelson, Scot C. (2007). "Banana and Plantain: An Overview with Emphasis on Pacific Island Cultivars". In Elevitch, C. R. (ed.). Species Profiles for Pacific Island Agroforestry (PDF). Hōlualoa, HI: Permanent Agriculture Resources (PAR). pp. 1–27. Archived (PDF) from the original on January 1, 2016. Retrieved June 4, 2014.

{{cite book}}:|website=ignored (help) - Seekins, Donald M. (1993). Dolan, Ronald E. (ed.). Philippines: A Country Study. Washington, DC: United States Government Printing Office. ISBN 0-8444-0748-8.

- Wong, Carol; Kiew, Ruth; Argent, George; Set, Ohn; Lee, Sing Kong & Gan, Yik Yuen (2002). "Assessment of the Validity of the Sections in Musa (Musaceae) using ALFP". Annals of Botany. 90 (2): 231–238. doi:10.1093/aob/mcf170. PMC 4240415. PMID 12197520.

- Wood, Frances A.; Roberts, George A. F. (2005). Prance, Ghillean; Nesbitt, Mark (eds.). The Cultural History of Plants. New York, NY: Routledge. ISBN 0-415-92746-3.

- Worcester, Dean C. (1899) . The Philippine Islands and Their People. New York, NY: The Macmillan Company.

- Yllano, O. B., Diaz, M. G. Q., Lalusin, A. G., Laurena, A. C., & Tecson-Mendoza, E. M. (2020). Genetic Analyses of Abaca (Musa textilis Née) Germplasm from its Primary Center of Origin, the Philippines, Using Simple Sequence Repeat (SSR) Markers. Philippine Agricultural Scientist, 103(4).

External links

- The World Book encyclopedia set, 1988.

- See International Year of Natural Fibres 2009

- Christenhusz, M.J.M. (2009). "Typification of ornamental plants: Musa textilis (Musaceae)". Phytotaxa. 2: 53–54. doi:10.11646/phytotaxa.2.1.10.

- abacá A comprehensive pamphlet about Philippine abacá presented 1915 Panama Pacific International Exposition held in San Francisco. Online publication uploaded in Filipiniana.net

| Fibers | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Natural |

| ||||||||

| Synthetic |

| ||||||||

| Taxon identifiers | |

|---|---|

| Musa textilis |

|