| Revision as of 21:54, 8 December 2019 editGun Powder Ma (talk | contribs)Autopatrolled, Extended confirmed users, Pending changes reviewers16,796 edits Restore history section from illiterate mass deletion. Note that only those contents that describe a crankshaft/compound crank/crank with connecting rod was adopted from Crank (mechanism) and used here.← Previous edit | Latest revision as of 21:46, 26 November 2024 edit undoCitation bot (talk | contribs)Bots5,433,514 edits Altered url. URLs might have been anonymized. Add: jstor, date, authors 1-1. Removed URL that duplicated identifier. Removed access-date with no URL. Removed parameters. Some additions/deletions were parameter name changes. | Use this bot. Report bugs. | Suggested by Neko-chan | #UCB_webform 13/500 | ||

| (179 intermediate revisions by 82 users not shown) | |||

| Line 1: | Line 1: | ||

| {{Short description|Mechanism for converting reciprocating motion to rotation}} | |||

| {{Other uses}} | {{Other uses}} | ||

| ] | ] | ||

| A '''crankshaft''' is a |

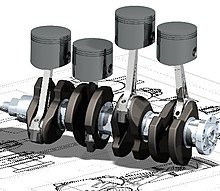

A '''crankshaft''' is a mechanical component used in a ] to convert the ] into ]. The crankshaft is a rotating ] containing one or more ]s,<ref name="Howacarworks.com">{{cite web |title=How the crankshaft works – All the details |url=https://www.howacarworks.com/crankshaft |website=How a Car Works |access-date=27 August 2022 |language=en}}</ref> that are driven by the ]s via the ]s.<ref>{{cite web |title=Definition of CRANKSHAFT |url=https://www.merriam-webster.com/dictionary/crankshaft |website=] |date=17 October 2024 |language=en}}</ref> | ||

| The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. | |||

| The crankshaft rotates within the engine block through use of ]s, and the crankpins rotate within the connecting rods using ]. Crankshafts are usually made from metal, with most modern crankshafts being constructed using forged steel. | |||

| Most modern crankshafts are located in the ]. They are made from ] or ], using either a ], ] or ] process. | |||

| ==History== | |||

| === Western World === | |||

| ==== Classical Antiquity ==== | |||

| {{See also|Roman technology|List of Roman watermills}} | |||

| ] crankshaft dated to the 2nd century AD. The right handle is lost.<ref name="Schiöler 2009, 113"/>]] | |||

| == Design == | |||

| A ] iron crankshaft of yet unknown purpose dating to the 2nd century AD was excavated in ], ]. The 82.5 cm long piece has fitted to one end a 15 cm long bronze handle, the other handle being lost.<ref>{{harvnb|Laur-Belart|1988|p=51–52, 56, fig. 42}}</ref><ref name="Schiöler 2009, 113">{{harvnb|Schiöler|2009|pp=113f.}}</ref> | |||

| ]s and ]s for a typical ]]] | |||

| ] | |||

| The crankshaft is located within the ] and held in place via ]s which allow the crankshaft to rotate within the block.<ref>{{cite web |title=Crankshaft: Parts, Function, Types, Diagram & More |url=https://www.theengineerspost.com/crankshaft-parts-and-function/ |website=The Engineers Post |access-date=1 September 2022 |language=en-us |date=27 May 2021}}</ref> The up-down motion of each piston is transferred to the crankshaft via ].<ref>{{cite book |last1=McCune |first1=R. C. |last2=Weber |first2=G. A. |chapter=Automotive Engine materials |title=Encyclopedia of Materials: Science and Technology |date=1 January 2001 |pages=426–434 |chapter-url=https://www.sciencedirect.com/science/article/pii/B0080431526000863 |access-date=1 September 2022 |publisher=Elsevier |doi=10.1016/B0-08-043152-6/00086-3 |bibcode=2001emst.book..426M |isbn=9780080431529 |language=en}}</ref> A ] is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration.<ref>{{cite web |title=How Does A Flywheel Work? Explained In Simple Words |url=https://carfromjapan.com/article/industry-knowledge/how-does-a-flywheel-work/ |website=Car From Japan |access-date=1 September 2022 |date=13 June 2018}}</ref> | |||

| ] from the 3rd century AD, the earliest known machine to combine a crank with a connecting rod.<ref name="Ritti, Grewe, Kessener 2007, 161"/>]] | |||

| A crankshaft is subjected to enormous stresses, in some cases more than {{convert|19000|lb|tonne|1|abbr=off|order=flip}} per cylinder.<ref>{{cite web |title=How to Build Racing Engines: Crankshafts Guide |url=https://www.musclecardiy.com/performance/how-to-build-racing-engines-crankshafts-guide/ |website=www.musclecardiy.com |accessdate=27 October 2019 |date=5 April 2015}}</ref> Crankshafts for ]s are usually a simpler design than for engines with multiple cylinders. | |||

| The earliest evidence, anywhere in the world, for a crank and ] in a machine appears in the late Roman ] from the 3rd century AD and two Roman stone ]s at ], ], and ], ] (both 6th century AD).<ref name="Ritti, Grewe, Kessener 2007, 161">{{harvnb|Ritti|Grewe|Kessener|2007|p=161}}: {{quote|Because of the findings at Ephesus and Gerasa the invention of the crank and connecting rod system has had to be redated from the 13th to the 6th c; now the Hierapolis relief takes it back another three centuries, which confirms that water-powered stone saw mills were in use when ] wrote his Mosella.}}</ref> On the ] of the Hierapolis mill, a ] fed by a ] is shown transmitting power through a ] to two ]s, which cut rectangular blocks by way of some kind of connecting rods and, through mechanical necessity, cranks. The accompanying inscription is in ].<ref>{{harvnb|Ritti|Grewe|Kessener|2007|pp=139–141}}</ref> | |||

| ===Bearings=== | |||

| The crank and connecting rod mechanisms of the other two archaeologically attested sawmills worked without a ].<ref>{{harvnb|Ritti|Grewe|Kessener|2007|pp=149–153}}</ref><ref>{{harvnb|Mangartz|2010}}</ref> In ancient literature, we find a reference to the workings of water-powered ] saws close to ], now ], by the late 4th century poet ];<ref name="Ritti, Grewe, Kessener 2007, 161"/> about the same time, these mill types seem also to be indicated by the ] ] from ], demonstrating a diversified use of water-power in many parts of the ].<ref>{{harvnb|Wilson|2002|p=16}}</ref> The three finds push back the date of the invention of the crank and connecting rod back by a full millennium;<ref name="Ritti, Grewe, Kessener 2007, 161"/> for the first time, all essential components of the much later ] were assembled by one technological culture: | |||

| {{main|Main bearing}} | |||

| The crankshaft is able to rotate in the ] due to the 'main ]'. Since the crankshaft is subject to large horizontal and ] from each cylinder, these main bearings are located at various points along the crankshaft, rather than just one at each end.<ref>{{cite web |title=Flat-Plane Cranks, Part 2 — Calculating Crankshaft Secondary Forces |url=https://www.enginelabs.com/tech-stories/flat-plane-cranks-part-2-calculating-crankshaft-secondary-forces/ |website=EngineLabs |access-date=28 August 2022 |date=20 January 2022}}</ref> The number of main bearings is determined based on the overall load factor and the maximum engine speed. Crankshafts in ] often use a main bearing between every cylinder and at both ends of the crankshaft, due to the high forces of combustion present.<ref>{{cite book |last1=Bosch |first1=Robert |title=Automotive Handbook |date=2004 |publisher=Robert Bosch |isbn=978-0-8376-1243-0 |page=465 |url=https://books.google.com/books?id=_t1oPwAACAAJ |access-date=28 August 2022 |language=en}}</ref> | |||

| {{quote|With the crank and connecting rod system, all elements for constructing a steam engine (invented in 1712) — ]'s ] (generating steam power), the ] and ] (in metal force pumps), non-return ] (in water pumps), ] (in water mills and clocks) — were known in Roman times.<ref>{{harvnb|Ritti|Grewe|Kessener|2007|p=156, fn. 74}}</ref>}} | |||

| Flexing of the crankshaft was a factor in ]s replacing ]s in the 1950s; the long crankshafts of the latter suffered from an unacceptable amount of flex when engine designers began using higher ]s and higher engine speeds (RPM).<ref>{{cite web |title=A Brief History Of The Straight-Eight Engine – Carole Nash |url=https://www.carolenash.com/news/classic-car-news/detail/a-brief-history-of-the-straight-eight-engine |website=Carole Nash UK |access-date=28 August 2022 |language=en}}</ref> | |||

| ==== Middle Ages ==== | |||

| {{See also|Medieval technology}} | |||

| ]'s war carriage]] | |||

| ===Piston stroke=== | |||

| The Italian physician ] (c. 1280−1349), planning for a new crusade, made illustrations for a ] and war carriages that were propelled by manually turned compound cranks and gear wheels (center of image).<ref>{{harvnb|Hall|1979|p=80}}</ref> The ], dating to around 1340, describes a grindstone rotated by two cranks, one at each end of its axle; the geared hand-mill, operated either with one or two cranks, appeared later in the 15th century;<ref name="White, Jr. 1962, 111">{{harvnb|White, Jr.|1962|p=111}}</ref> | |||

| The distance between the axis of the ] and the axis of the crankshaft determines the ] of the engine.<ref name="Howacarworks.com"/> | |||

| Most modern car engines are classified as "over square" or short-stroke,{{citation needed|date=August 2022}} wherein the stroke is less than the diameter of the ]. A common way to increase the low-RPM torque of an engine is to increase the stroke, sometimes known as "stroking" the engine. Historically, the trade-off for a long-stroke engine was a lower rev limit and increased vibration at high RPM, due to the increased piston velocity.<ref>{{cite web |title=All you need to know about stroker engines and kits |url=https://www.torquecars.com/tuning/stroker-engines.php |website=TorqueCars |access-date=28 August 2022 |date=22 December 2020}}</ref> | |||

| ==== Renaissance ==== | |||

| {{See also|Renaissance technology}} | |||

| ])]] | |||

| === Cross-plane and flat-plane configurations === | |||

| The first depictions of the compound crank in the carpenter's ] appear between 1420 and 1430 in various northern European artwork.<ref name="White, Jr. 1962, 112">{{harvnb|White, Jr.|1962|p=112}}</ref> The rapid adoption of the compound crank can be traced in the works of the ], an unknown German engineer writing on the state of the military technology of his day: first, the connecting-rod, applied to cranks, reappeared, second, double compound cranks also began to be equipped with connecting-rods and third, the flywheel was employed for these cranks to get them over the 'dead-spot'.<ref name="White, Jr. 1962, 113">{{harvnb|White, Jr.|1962|p=113}}</ref> | |||

| When designing an engine, the crankshaft configuration is closely related to the engine's ].<ref>{{cite web |title=What's the best firing order? |url=https://www.enginelabs.com/engine-tech/engine/firing-order-swaps-whats-best-for-your-engine/ |website=EngineLabs |access-date=30 August 2022 |date=25 April 2017}}</ref><ref>{{cite web |title=Crankshaft Design Evolution |url=http://enginehistory.org/members/articles/CrankDesignEvol.shtml |website=enginehistory.org |access-date=30 August 2022}}</ref> | |||

| Most production V8 engines (such as the ] and the ]) use a ] whereby the crank throws are spaced 90 degrees apart.<ref>{{cite web |title=Flat Plane Crankshafts vs. Crossplane Crankshafts |url=https://www.onallcylinders.com/2015/01/15/cross-plane-vs-flat-plane-crankshafts/ |website=OnAllCylinders |access-date=30 August 2022 |language=en |date=15 January 2015}}</ref> However, some high-performance V8 engines (such as the ])<ref>{{cite web |title=Ferrari 488 Spider debuts in Frankfurt, is faster than Lamborghini's new drop-top in every way |url=https://www.autoweek.com/news/auto-shows/a1876761/ferrari-488-spider-drops-its-top-frankfurt-motor-show/ |website=Autoweek |access-date=30 August 2022 |date=15 September 2015}}</ref><ref>{{cite web |title=2016 Ferrari 488 Spider: Losing the Roof Doesn't Compromise the Magic |url=https://www.roadandtrack.com/new-cars/first-drives/reviews/a27051/the-ferrari-488-spider-is-not-compromised-is-really-great/ |website=Road & Track |access-date=30 August 2022 |date=15 October 2015}}</ref> instead use a ], whereby the throws are spaced 180° apart, which essentially results in two inline-four engines sharing a common crankcase. Flat-plane engines are usually able to operate at higher RPM, however they have higher second-order vibrations,<ref>{{cite web |title=Difference Between Cross-Plane and Flat-Plane Cranks |url=https://www.motortrend.com/how-to/difference-between-cross-plane-and-flat-plane-cranks/ |website=MotorTrend |access-date=30 August 2022 |language=en |date=15 June 2022}}</ref> so they are better suited to racing car engines.<ref>{{cite web |title=How The Flat-Plane Crank Turns Muscle Cars Into Exotics |url=https://carbuzz.com/news/carbuzz-explains-how-the-flat-plane-crank-turns-muscle-cars-into-exotics |website=CarBuzz |access-date=30 August 2022 |language=en-us |date=8 April 2016}}</ref> | |||

| In ], the earliest evidence of a compound crank and connecting-rod is found in the sketch books of ], but the device is still mechanically misunderstood.<ref name="White, Jr. 1962, 113"/> A sound grasp of the crank motion involved demonstrates a little later ] who painted a piston-pump driven by a water-wheel and operated by two simple cranks and two connecting-rods.<ref name="White, Jr. 1962, 113"/> | |||

| ===Engine balance=== | |||

| ], 1661)]] | |||

| For some engines it is necessary to provide ]s for the reciprocating mass of the piston, conrods and crankshaft, in order to improve the ].<ref>{{cite web |title=Crankshaft Balance Factors |url=http://ohiocrank.com/crankshaft-balance-factors/ |website=Ohio Crankshaft |access-date=31 August 2022}}</ref><ref>{{cite web |title=Finding Balance (Part 1): The Basics of Crankshaft Balancing |url=https://www.onallcylinders.com/2016/03/17/the-basics-of-crankshaft-balancing/ |website=OnAllCylinders |access-date=31 August 2022 |language=en |date=17 March 2016}}</ref> These counterweights are typically cast as part of the crankshaft but, occasionally, are bolt-on pieces.{{citation needed|date=August 2022}} | |||

| ===Flying arms=== | |||

| One of the drawings of the Anonymous of the Hussite Wars shows a boat with a pair of paddle-wheels at each end turned by men operating compound cranks (see above). The concept was much improved by the Italian ] in 1463, who devised a boat with five sets, where the parallel cranks are all joined to a single power source by one connecting-rod,<ref>See </ref> an idea also taken up by his compatriot ].<ref name="White, Jr. 1962, 114">{{harvnb|White, Jr.|1962|p=114}}</ref> | |||

| ]s on a crankshaft) ]] | |||

| In some engines, the crankshaft contains direct links between adjacent ], without the usual intermediate main bearing. These links are called ''flying arms''.<ref name="Nunney">{{cite book |title=Light and Heavy Vehicle Technology|first=Malcolm J.|last=Nunney|year=2007|edition=4th|isbn=978-0-7506-8037-0|publisher=Elsevier Butterworth-Heinemann}}</ref>{{refpage |pages=16, 41}} This arrangement is sometimes used in ] and ]s, in order to maintain an even firing interval while using different V angles, and to reduce the number of main bearings required. The downside of flying arms is that the rigidity of the crankshaft is reduced, which can cause problems at high RPM or high power outputs.<ref>{{cite web |title=Crankshaft guide – Flat vs Cross plane & lightened crankshafts |url=https://www.torquecars.com/tuning/crankshafts.php |website=TorqueCars |access-date=31 August 2022 |date=30 June 2015}}</ref> | |||

| {{clear|left}} | |||

| === Counter-rotating crankshafts === | |||

| Crankshafts were also described by ] (d. 1405), ] (1452–1519)<ref name=Crank/> and a Dutch "farmer" by the name ] van Uitgeest in 1592. His wind-powered ] used a crankshaft to convert a windmill's circular motion into a back-and-forward motion powering the saw. Corneliszoon was granted a ] for his crankshaft in 1597. | |||

| In most engines, each ] is attached a single crankshaft, which results in the angle of the connecting rod varying as the ] moves through its stroke. This variation in angle pushes the pistons against the cylinder wall, which causes friction between the piston and cylinder wall.<ref>{{citation|title=Company's perspective in vehicle tribology. In: 18th Leeds-Lyon Symposium (eds D Dowson, CM Taylor and MGodet), Lyon, France, 3–6 September 1991|author=Andersson BS|publisher= New York: Elsevier|year=1991|pages=503–506}}</ref> To prevent this, some early engines – such as the 1900–1904 ] flat-twin engines – connected each piston to two crankshafts that are rotating in opposite directions. This arrangement cancels out the lateral forces and reduces the requirement for counterweights. This design is rarely used, however a similar principle applies to ]s, which are occasionally used. | |||

| ==Construction== | |||

| From the 16th century onwards, evidence of cranks and connecting rods integrated into machine design becomes abundant in the technological treatises of the period: ]'s ''The Diverse and Artifactitious Machines'' of 1588 alone depicts eighteen examples, a number that rises in the ''Theatrum Machinarum Novum'' by ] to 45 different machines, one third of the total.<ref>{{harvnb|White, Jr.|1962|p=172}}</ref> | |||

| {{unreferenced section|date=September 2022}} | |||

| === |

=== Forged crankshafts === | ||

| ] | |||

| ] (1136–1206) described a crank and connecting rod system in a rotating machine in two of his water-raising machines.<ref name=Crank>]. .</ref> His twin-cylinder ] incorporated a crankshaft,<ref>{{citation|title=Islam and Science, Medicine, and Technology|last=Sally Ganchy|first=Sarah Gancher|publisher=The Rosen Publishing Group|year=2009|isbn=1-4358-5066-1|page=41}}</ref> but the device was unnecessarily complex indicating that he still did not fully understand the concept of power conversion.<ref>{{harvnb|White, Jr.|1962|p=170}}: {{quote|However, that al-Jazari did not entirely grasp the meaning of the crank for joining reciprocating with rotary motion is shown by his extraordinarily complex pump powered through a cog-wheel mounted eccentrically on its axle.}}</ref> In China, the potential of the crank of converting circular motion into reciprocal one never seems to have been fully realized, and the crank was typically absent from such machines until the turn of the 20th century.<ref>{{harvnb|White, Jr.|1962|p=104}}: {{quote|Yet a student of the Chinese technology of the early twentieth century remarks that even a generation ago the Chinese had not 'reached that stage where continuous rotary motion is substituted for reciprocating motion in technical contrivances such as the drill, lathe, saw, etc. To take this step familiarity with the crank is necessary. The crank in its simple rudimentary form we find in the Chinese windlass, which use of the device, however, has apparently not given the impulse to change reciprocating into circular motion in other contrivances'. In China the crank was known, but remained dormant for at least nineteen centuries, its explosive potential for applied mechanics being unrecognized and unexploited.}}</ref> | |||

| Crankshafts can be created from a steel bar using ]. Today, manufacturers tend to favour the use of forged crankshafts due to their lighter weight, more compact dimensions and better inherent damping.<ref>{{Cite web |title=Cast vs Forged Crankshaft |url=https://www.dropforging.net/cast-vs-forged-crankshaft.html |access-date=2024-07-31 |website=www.dropforging.net}}</ref> With forged crankshafts, ] micro-alloyed steels are mainly used as these steels can be air-cooled after reaching high strengths without additional heat treatment, except for the surface hardening of the bearing surfaces. The low alloy content also makes the material cheaper than high-alloy steels. Carbon steels also require additional heat treatment to reach the desired properties. | |||

| == Design == | |||

| ] | |||

| ] | |||

| === Cast crankshafts === | |||

| The crankshaft is supported by the ], with the engine's ]s allowing the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via ]. A ] is often attached to the front end of the crankshaft, in order to smoothen the power delivery and reduce torsional vibration. | |||

| Another construction method is to ] the crankshaft from ductile iron. ] crankshafts are today mostly found in cheaper production engines where the loads are lower. | |||

| === Machined crankshafts === | |||

| A crankshaft is subjected to enormous stresses, in some cases more than {{convert|19000|lb|tonne|1|abbr=off|order=flip}} per cylinder.<ref>{{cite web |title=How to Build Racing Engines: Crankshafts Guide |url=https://www.musclecardiy.com/performance/how-to-build-racing-engines-crankshafts-guide/ |website=www.musclecardiy.com |accessdate=27 October 2019 |date=5 April 2015}}</ref> Crankshafts for ]s are usually a simpler design than for engines with multiple cylinders. | |||

| Crankshafts can also be ] from ], often a bar of high quality ]. Though the fiber flow (local inhomogeneities of the material's chemical composition generated during casting) does not follow the shape of the crankshaft (which is undesirable), this is usually not a problem since higher quality steels, which normally are difficult to forge, can be used. Per unit, these crankshafts tend to be expensive due to the large amount of material that must be removed with lathes and milling machines, the high material cost, and the additional heat treatment required. However, since no expensive tooling is needed, this production method allows small production runs without high up-front costs. | |||

| == |

==History== | ||

| {{main|Main bearing}} | |||

| === Crank === | |||

| The crankshaft is able to rotate in the engine block due to the main bearings. Since the crankshaft is subject to large sideways forces from each cylinder, bearings are located at various points along the crankshaft, not just one at each end. This was a factor in ]s replacing ]s in the 1950s. The long crankshafts of the latter suffered from an unacceptable amount of flex when engine designers began using higher ]s and higher engine speeds (RPM). High performance engines often have more main bearings than their lower performance cousins for this reason. | |||

| {{Main|Crank (mechanism)#History}} | |||

| === |

==== Asia ==== | ||

| ] are a form of hand-operated crank.<ref name="Ritti, Grewe, Kessener 2007, 159">{{harvnb|Ritti|Grewe|Kessener|2007|p=159}}</ref><ref name="Lucas 2005, 5, fn. 92">{{harvnb|Lucas|2005|p=5, fn. 9}}</ref>]]{{see also|Science and technology of the Han dynasty}} | |||

| Most production V8 engines use crank throws spaced 90° apart, which is called a "cross-plane" configuration (such as the ] and the ]). Several high-performance V8 engines (such as the ]) instead use use a "flat-plane" crankshaft with throws spaced 180° apart, essentially resulting in two ]s running in a common crankcase. | |||

| The earliest hand-operated ] appeared in China during the ] (202 BC – 220 AD). They were used for silk-reeling, hemp-spinning, for the agricultural ] fan, in the water-powered flour-sifter, for hydraulic-powered metallurgic ], and in the well ].<ref name="needham volume 4 part 2 118">{{harvnb|Needham|1986|pp=118–119}}</ref> Pottery models with crank operated winnowing fans were unearthed dating back to the Western Han dynasty (202 BC - 9 AD).<ref name="Yan">{{cite book |last1=Lisheng |first1=Feng |last2=Qingjun |chapter=Crank-Connecting Rod Mechanism: Its Application in Ancient China and Its Origins |first2=Tong |editor1=Hong-Sen Yan |editor2=Marco Ceccarelli |title=International Symposium on History of Machines and Mechanisms |chapter-url=https://books.google.com/books?id=Dkq6_mdW43IC&pg=PA249 |publisher=Springer Science and Business Media|isbn=978-1-4020-9484-2|page=247|year=2009 }}</ref><ref name="needham volume 4 part 2 118"/> The rotary winnowing fan greatly increased the efficiency of separating grain from husks and stalks.<ref>{{Cite book |title=A Brief Illustrated History of Machines and Mechanisms |last1= Bautista Paz |first1=Emilio |last2=Ceccarelli |first2=Marco |last3= Otero |first3=Javier Echávarri |last4= Sanz |first4=José Luis Muñoz |publisher=Springer |year=2010 |isbn=978-9048125111 |publication-date=May 12, 2010 |page=19}}</ref><ref>{{Cite book |title=Understanding China: Dangerous Resentments |last= Du Bois |first=George |publisher=Trafford on Demand |year= 2014 |isbn=978-1490745077}}</ref> The Chinese used the crank-and-connecting rod in ancient blasting apparatus, textile machinery and agricultural machinery no later than the Western Han dynasty (202 BC – 9 AD). Eventually crank-and-connecting rods were used in the inter-conversion or rotary and reciprocating motion for other applications such as flour-sifting, treadle spinning wheels, water-powered furnace bellows, and silk-reeling machines.<ref>{{harvnb|Lisheng|Qingjun|2009|pp=236–249}}</ref><ref name="needham volume 4 part 2 118"/> | |||

| Flat-plane engines are usually able to rev higher, however they have more vibration. Flat-plane crankshafts were used on several early V8 engines. See the main article on ] crankshafts. | |||

| === |

==== Middle East ==== | ||

| Ancient Egyptians had manual drills resembling a crank at the time of the ] (2686–2181 BCE) and even a hieroglyph for the tool.<ref>{{Cite book |last=Needham |first=Joseph |title=Mechanical engineering |date=2007 |publisher=Cambridge Univ. Press |isbn=978-0-521-05803-2 |edition=6. print |series=Science and civilisation in China / by Joseph Needham Vol. 4, Physics and physical technology |location=Cambridge |pages=114}}</ref> However the Ancient Egyptian drill did not operate as a true crank.<ref>{{Cite journal |last1=Hartenberg |first1=Richard S. |last2=Schmidt |first2=John |date=1969 |title=The Egyptian Drill and the Origin of the Crank |url=https://www.jstor.org/stable/3101475 |journal=Technology and Culture |volume=10 |issue=2 |pages=155–165 |doi=10.2307/3101475 |jstor=3101475 |issn=0040-165X}}</ref> | |||

| For some engines it is necessary to provide ]s for the reciprocating mass of each piston and connecting rod to improve ]. These are typically cast as part of the crankshaft but, occasionally, are bolt-on pieces. | |||

| Later evidence for the crank, combined with a connecting rod in a machine, appears in the Ancient Greek ] in ] from the 3rd century AD and two stone ]s at ], ], and ], Greek Ionia under Rome, (both 6th century AD).<ref name="Ritti, Grewe, Kessener 2007, 1612">{{harvnb|Ritti|Grewe|Kessener|2007|p=161}}: {{blockquote|Because of the findings at Ephesus and Gerasa the invention of the crank and connecting rod system has had to be redated from the 13th to the 6th c; now the Hierapolis relief takes it back another three centuries, which confirms that water-powered stone saw mills were indeed in use when ] wrote his Mosella.}}</ref> On the ] of the Hierapolis mill, a ] fed by a ] is shown powering via a ] two ]s which cut rectangular blocks by the way of some kind of connecting rods and, through mechanical necessity, cranks. The accompanying inscription is in ].<ref name=":02">{{harvnb|Ritti|Grewe|Kessener|2007|pp=139–141}}</ref> The crank and connecting rod mechanisms of the other two archaeologically attested sawmills worked without a gear train.<ref name=":12">{{harvnb|Ritti|Grewe|Kessener|2007|pp=149–153}}</ref><ref name=":22">{{harvnb|Mangartz|2006|pp=579f.}}</ref> | |||

| In 1916, the ] began production of the first engines to use balanced crankshafts, which allowed the engine to run at higher speeds (RPM) than contemporary engines. | |||

| The crank appears in the mid-9th century in several of the hydraulic devices described by the ] brothers in their '']''.<ref name="Beeston">{{citation |last=A. F. L. Beeston, M. J. L. Young |first=J. D. Latham, Robert Bertram Serjeant |title=The Cambridge History of Arabic Literature |page=266 |year=1990 |publisher=] |isbn=0-521-32763-6}}</ref> These devices, however, made only partial rotations and could not transmit much power,<ref>{{harvnb|al-Hassan|Hill|1992|pp=45, 61}}</ref> although only a small modification would have been required to convert it to a crankshaft.<ref name="Hill19792">{{citation |author=] |title=The Book of Ingenious Devices (Kitáb al-Ḥiyal) by the Banú (sons of) Músà bin Shákir |pages=23–4 |year=1979 |url=https://books.google.com/books?id=MdpAo6SaOL0C&pg=PA23 |publisher=Springer Publishing |isbn=90-277-0833-9 |last2=Hill |first2=Donald Routledge |author-link2=Donald Hill}}</ref> | |||

| ===Flying arms=== | |||

| ] | |||

| In some engines, the crankshaft contains direct links between adjacent crank pins, without the usual intermediate main bearing. These links are called ''flying arms''.<ref name="Nunney">{{cite book |title=Light and Heavy Vehicle Technology|first=Malcolm J.|last=Nunney|year=2007|edition=4th|isbn=978-0-7506-8037-0|publisher=Elsevier Butterworth-Heinemann}}</ref>{{refpage |pages=16, 41}} This arrangement is sometimes used in ] and ]s, as it enables the engine to be designed with different V angles than what would otherwise be required to create an even firing interval, while still using fewer main bearings than would normally be required with a single piston per crankthrow. This arrangement reduces weight and engine length at the expense of reduced crankshaft rigidity. | |||

| ] (1136–1206) described a crank and connecting rod system in a rotating machine in two of his water-raising machines.<ref name="Crank2">]. .</ref> His twin-cylinder ] incorporated a crankshaft.<ref>{{citation |last=Sally Ganchy |first=Sarah Gancher |title=Islam and Science, Medicine, and Technology |page= |year=2009 |url=https://archive.org/details/islamsciencemedi0000ganc/page/41 |publisher=The Rosen Publishing Group |isbn=978-1-4358-5066-8 |url-access=registration}}</ref> A crank is later also described in an early 15th century Arabic manuscript of ]'s ''Mechanics''.<ref name="White Jr. 1962, 170">{{harvnb|White|1962|p=170}}</ref> | |||

| ===Piston stroke=== | |||

| The distance the axis of the crank throws from the axis of the crankshaft determines the ] of the engine. | |||

| ==== Europe and Roman Empire ==== | |||

| Most modern car engines are classified as "over square" or short-stroke, wherein the stroke is less than the diameter of the ]. A common way to increase the low-RPM torque of an engine is to increase the stroke, sometimes known as "stroking" the engine. Traditionally, the trade-off for a long-stroke engine was reduced power and increased vibration at high RPM. | |||

| {{see also|List of Roman watermills|Medieval technology|Renaissance technology}}] in ] (3rd century), a machine that combines a crank with a connecting rod.<ref name="Ritti, Grewe, Kessener 2007, 161">{{harvnb|Ritti|Grewe|Kessener|2007|p=161}}: Because of the findings at Ephesus and Gerasa the invention of the crank and connecting rod system has had to be redated from the 13th to the 6th c; now the Hierapolis relief takes it back another three centuries, which confirms that water-powered stone saw mills were indeed in use when Ausonius wrote his Mosella.</ref>|320x320px]] | |||

| {{clear right}} | |||

| The first rotary hand mills, or rotary querns, appeared in Spain (600 BC – 500 BC),<ref name="Ritti et al. 2007, 159">{{harvnb|Ritti|Grewe|Kessener|2007|pp=158, 159}}</ref><ref name=":0">{{Cite journal |last=Alonso i Martínez |first=Natalia |date=2015 |title="Moliendo en ibero, moliendo en griego": aculturación y resistencia tecnológica en el Mediterráneo occidental durante la Edad del Hierro |url=https://dialnet.unirioja.es/servlet/articulo?codigo=5294175 |journal=Vegueta: Anuario de la Facultad de Geografía e Historia |issue=15 |pages=23–36 |issn=1133-598X}}</ref> before they spread to the East.<ref name="Ritti et al. 2007, 159" /><ref name=":0" /> The handle near the outer edge of the rotary part being the crank<ref name="Ritti et al. 2007, 159" /><ref name="Lucas 2005, 5, fn. 92"/><ref>{{Cite book |last=Needham |first=Joseph |url=https://books.google.com/books?id=SeGyrCfYs2AC |title=Science and Civilisation in China, Part 2, Mechanical Engineering |date=1965-01-02 |publisher=Cambridge University Press |isbn=978-0-521-05803-2 |pages=186 |language=en}}</ref> and human arm powering the rotation would be the connecting rod.<ref name="Ritti et al. 2007, 159" /> However according to F. Lisheng and T. Qingjun, the hand-crank of the rotary quern was different from a crank, which was the combination of a hand-crank and a push-and-pull connecting rod by a hinge.<ref name=":1">{{harvnb|Lisheng|Qingjun|2009|pp=248-249}}.</ref> | |||

| === Counterweights === | |||

| Some high performance crankshafts also use heavy-metal counterweights to make the crankshaft more compact. The heavy-metal used is most often a ] alloy but ] has also been used. A cheaper option is to use ], but compared with tungsten its density is much lower. | |||

| The Antikythera mechanism, dated to around 200 BC,<ref>{{Citation |last1=Voulgaris |first1=Aristeidis |title=The Initial Calibration Date of the Antikythera Mechanism after the Saros spiral mechanical Apokatastasis |date=2023-08-27 |arxiv=2203.15045 |last2=Mouratidis |first2=Christophoros |last3=Vossinakis |first3=Andreas}}</ref><ref>{{Cite journal |last=Carman |first=Christián C. |date=2017 |title=The Final Date of the Antikythera Mechanism |url=http://journals.sagepub.com/doi/10.1177/0021828617721553 |journal=Journal for the History of Astronomy |language=en |volume=48 |issue=3 |pages=312–323 |doi=10.1177/0021828617721553 |issn=0021-8286|hdl=11336/72114 |hdl-access=free }}</ref> used a crank as a part of its mechanism.<ref>{{Citation |last=Tyaglova-Fayer |first=Svetlana |title=The new reading of the 3D reconstruction of the Antikythera machine (30-day calendar) |date=2023-11-14 |url=https://shs.hal.science/halshs-04223993v3 |access-date=2024-08-25 |language=en}}</ref> The crank was used to manually introduce dates.<ref>{{Cite journal |last1=Diolatzis |first1=Ioannis S. |last2=Pavlogeorgatos |first2=Gerasimos |date=2018-03-01 |title=Deepening to Antikythera mechanism via its interactivity |url=https://www.sciencedirect.com/science/article/abs/pii/S221205481730022X |journal=Digital Applications in Archaeology and Cultural Heritage |volume=8 |pages=10–26 |doi=10.1016/j.daach.2017.11.005 |issn=2212-0548}}</ref> | |||

| === Counter-rotating crankshafts === | |||

| The conventional design for piston engines is where each connecting rod is attached to one crankshaft, with the angle of the connecting rod varying as the piston moves through its stroke. This variation in angle results in lateral forces on the pistons, pushing the pistons against the cylinder wall. This lateral force causes additional friction between the piston and cylinder wall<ref>{{citation|title=Company's perspective in vehicle tribology. In: 18th Leeds-Lyon Symposium (eds D Dowson, CM Taylor and MGodet), Lyon, France, 3-6 September 1991|author=Andersson BS|publisher= New York: Elsevier|year=1991|pages=503–506}}</ref> and can cause additional wear on the cylinder wall. | |||

| Evidence for the crank combined with a connecting rod, appears in the Ancient Greek ], dating to the 3rd century AD under the Roman Empire; they are also found in stone ]s in ] and ], Greek Ionia under Rome, dating to the 6th century.<ref name="Ritti, Grewe, Kessener 2007, 161" /> The ] of the Hierapolis mill shows a ] fed by a ] powering via a ] two ]s which cut blocks by the way of some kind of connecting rods and cranks.<ref name=":02"/> The crank and connecting rod mechanisms of the other two archaeologically attested sawmills worked without a gear train.<ref name=":12"/><ref>{{harvnb|Mangartz|2010|pp=579f.}}</ref>] | |||

| To avoid these lateral forces, each piston can be connected to two crankshafts that are rotating in opposite directions, which cancels out the lateral forces. This arrangement also reduces the requirement for counterweights, reducing the mass of the crankshaft. An early example of a counter-rotating crankshaft arrangement is the 1900-1904 ] flat-twin engines. | |||

| A Roman iron crank dating to the 2nd century AD was excavated in ], ].<ref name="Schiöler 2009, 113">{{harvnb|Schiöler|2009|pp=113f.}}</ref><ref>{{harvnb|Laur-Belart|1988|pp=51–52, 56, fig. 42}}</ref> The crank-operated ] mill is dated to the late 2nd century.<ref>{{harvnb|Volpert|1997|pp=195, 199}}</ref> | |||

| == Construction == | |||

| {{refimprove section|small=yes|date=October 2019}} | |||

| Water-powered ] saws in ] were mentioned by the late 4th century poet ];<ref name="Ritti, Grewe, Kessener 2007, 161"/> about the same time, these mill types seem also to be indicated by Greek Saint ] from ].<ref>{{harvnb|Wilson|2002|p=16}}</ref><ref name="Ritti, Grewe, Kessener 2007, 161"/><ref>{{harvnb|Ritti|Grewe|Kessener|2007|p=156, fn. 74}}</ref> | |||

| === Forging, casting and machining === | |||

| ] marine crankshafts, 1942]] | |||

| ] | |||

| The most common construction methods for crankshafts are forging (usually through roll forging) or casting. Most crankshafts are made in a single piece, however some smaller and larger engines use crankshafts assembled from multiple pieces. | |||

| A rotary ]<ref name="White Jr. 1962, 110">{{harvnb|White|1962|p=110}}</ref> operated by a crank handle is shown in the ] manuscript '']''; the pen drawing of around 830 goes back to a late antique original.<ref>{{harvnb|Hägermann|Schneider|1997|pp=425f.}}</ref> Cranks used to turn wheels are also depicted or described in various works dating from the tenth to thirteenth centuries.<ref name="White Jr. 1962, 110"/><ref>{{harvnb|Needham|1986|pp=112–113}}.</ref> | |||

| Recently{{when|date=October 2019}}, ] has become the most common construction method for crankshafts, due to their lighter weight, more compact dimensions and better inherent damping. With forged crankshafts, ] microalloyed steels are mostly used as these steels can be air cooled after reaching high strengths without additional heat treatment (aside from the surface hardening of the bearing journals). The low alloy content also makes the material cheaper than high alloy steels. | |||

| The first depictions of the compound crank in the carpenter's ] appear between 1420 and 1430 in northern European artwork.<ref name="White Jr. 1962, 112">{{harvnb|White|1962|p=112}}</ref> The rapid adoption of the compound crank can be traced in the works of an unknown German engineer writing on the state of military technology during the Hussite Wars: first, the connecting-rod, applied to cranks, reappeared; second, double-compound cranks also began to be equipped with connecting-rods; and third, the flywheel was employed for these cranks to get them over the 'dead-spot'.<ref name="White Jr. 1962, 113">{{harvnb|White|1962|p=113}}</ref> The concept was much improved by the Italian engineer and writer ] in 1463, who devised a boat with five sets, where the parallel cranks are all joined to a single power source by one connecting-rod, an idea also taken up by his compatriot Italian painter ].<ref name="White Jr. 1962, 114">{{harvnb|White|1962|p=114}}</ref> | |||

| ] (using ]) is today mostly used for crankshafts in cheaper, lower performance engines. | |||

| The crank had become common in Europe by the early 15th century, as seen in the works of the military engineer ] (1366–after 1405).<ref name="needham volume 4 part 2 113">{{harvnb|Needham|1986|p=113}}.</ref><ref name="White Jr. 1962, 111"/> Devices depicted in Kyeser's '']'' include cranked windlasses for spanning siege crossbows, cranked chain of buckets for water-lifting and cranks fitted to a wheel of bells.<ref name="White Jr. 1962, 111"/> Kyeser also equipped the ]s for water-raising with a crank handle, an innovation which subsequently replaced the ancient practice of working the pipe by treading.<ref>{{harvnb|White|1962|pp=105, 111, 168}}</ref> | |||

| Crankshafts can also be ] out of a ] of steel. These crankshafts tend to be expensive due to the large amount of material that must be removed with lathes and milling machines, the high material cost, and the additional heat treatment required. Since no expensive tooling is needed, this production method is mostly used for low-volume engines. In a machined crankshafts, the fibre flow (local inhomogeneities of the material caused by the casting process) does not follow the shape of the crankshaft, however this is rarely a problem since machined crankshafts often use higher quality steels than forged crankshafts. | |||

| ] painted a piston-pump driven by a water-wheel and operated by two simple cranks and two connecting-rods.<ref name="White Jr. 1962, 113"/> The 15th century also saw the introduction of cranked rack-and-pinion devices, called cranequins, which were fitted to the ]'s stock as a means of exerting even more force while spanning the missile weapon.<ref>{{harvnb|Hall|1979|pp=74f.}}</ref> In the textile industry, cranked ]s for winding skeins of yarn were introduced.<ref name="White Jr. 1962, 111">{{harvnb|White|1962|p=111}}</ref> | |||

| === Fatigue strength === | |||

| To improve the ], a radius is often rolled at the ends of each main and crankpin bearing. The radius itself reduces the stress in these critical areas, but since the radius in most cases is rolled, this also leaves some compressive residual stress in the surface, which prevents cracks from forming. | |||

| The '']'', dating to around 1340, describes a grindstone which was rotated by two cranks, one at each end of its axle; the geared hand-mill, operated either with one or two cranks, appeared later in the 15th century.<ref name="White Jr. 1962, 111" /> Around 1480, the early medieval rotary grindstone was improved with a treadle and crank mechanism. Cranks mounted on push-carts first appear in a German engraving of 1589.<ref>{{harvnb|White|1962|p=167}}</ref> | |||

| ] is a grinding process to produce a smooth finish on the surface of a metallic object, which is also used to prevent cracks developing from fatigue stress. | |||

| === |

=== Crankshaft === | ||

| In 9th century ] ], automatically operated cranks appear in several of the hydraulic devices described by the ] brothers in the '']''.<ref name="Beeston"/> These automatically operated cranks appear in several devices, two of which contain an action which approximates to that of a crankshaft, five centuries before the earliest known European description of a crankshaft. However, the automatic crank mechanism described by the ] would not have allowed a full rotation, but only a small modification was required to convert it to a crankshaft.<ref name="Hill19792"/> | |||

| Most mass-production crankshafts use ] for the bearing surfaces. Some high performance crankshafts, billet crankshafts in particular, use ] instead. For crankshafts that operate on roller bearings, the use of ] tends to be favored due to the high contact stresses in such situations. | |||

| In the ], Arab engineer ] (1136–1206) described a crank and connecting rod system in a rotating machine for two of his water-raising machines,<ref name="Crank2"/> which include both crank and ] mechanisms.<ref name="books.google.co.uk">] (2012), , ]</ref> | |||

| ]The Italian physician ] ({{Circa|1280|1349}}), planning for a new ], made illustrations for a ] and war carriages that were propelled by manually turned compound cranks and gear wheels,<ref>{{harvnb|Hall|1979|p=80}}</ref> identified as an early crankshaft prototype by ].<ref>{{cite book|title=Medieval Religion and Technology: Collected Essays|page=335|last1=Townsend White|first1=Lynn|year=1978|publisher=University of California Press|isbn=9780520035669|url-access=registration|url=https://archive.org/details/medievalreligion00whit}}</ref> | |||

| ] ]] | |||

| Crankshafts were described by ] (1452–1519)<ref name="Crank2"/> and a Dutch farmer and windmill owner by the name ] in 1592. His wind-powered ] used a crankshaft to convert a windmill's circular motion into a back-and-forward motion powering the saw. Corneliszoon was granted a ] for his crankshaft in 1597. | |||

| From the 16th century onwards, evidence of cranks and connecting rods integrated into machine design becomes abundant in the technological treatises of the period: ]'s ''The Diverse and Artifactitious Machines'' of 1588 depicts eighteen examples, a number that rises in the ''Theatrum Machinarum Novum'' by ] to 45 different machines.<ref>{{harvnb|White|1962|p=172}}</ref> Cranks were formerly common on some machines in the early 20th century; for example almost all ]s before the 1930s were powered by ] motors wound with cranks. Reciprocating piston engines use cranks to convert the linear piston motion into rotational motion. ]s of early 20th century ]s were usually started with hand cranks, before ] came into general use. | |||

| ==See also== | ==See also== | ||

| {{Commons |

{{Commons}} | ||

| {{Div col}} | {{Div col}} | ||

| *] | |||

| *] | |||

| *] | |||

| *] | |||

| *] | *] | ||

| *] | |||

| *] | *] | ||

| *] | *] | ||

| *] | |||

| *] | *] | ||

| *] | *] | ||

| *] | |||

| *] | |||

| {{div col end}} | {{div col end}} | ||

| ==References== | ==References== | ||

| {{Reflist |

{{Reflist}} | ||

| ==Sources== | |||

| *{{Citation | |||

| | last = Frankel | |||

| | first = Rafael | |||

| | title = The Olynthus Mill, Its Origin, and Diffusion: Typology and Distribution | |||

| | journal = ] | |||

| | pages = 1–21 | |||

| | issue = 1 | |||

| | volume = 107 | |||

| | year = 2003 | |||

| | doi=10.3764/aja.107.1.1 | |||

| | s2cid = 192167193 | |||

| }} | |||

| *{{Citation | |||

| | last1 = Hägermann | |||

| | first1 = Dieter | |||

| | last2 = Schneider | |||

| | first2 = Helmuth | |||

| | title = Propyläen Technikgeschichte. Landbau und Handwerk, 750 v. Chr. bis 1000 n. Chr. | |||

| | place = Berlin | |||

| | edition = 2nd | |||

| | year = 1997 | |||

| | isbn = 3-549-05632-X | |||

| }} | |||

| *{{Citation | |||

| | last = Hall | |||

| | first = Bert S. | |||

| | title = The Technological Illustrations of the So-Called "Anonymous of the Hussite Wars". Codex Latinus Monacensis 197, Part 1 | |||

| | place = Wiesbaden | |||

| | year = 1979 | |||

| | publisher = Dr. Ludwig Reichert Verlag | |||

| | isbn = 3-920153-93-6 | |||

| }} | |||

| *{{Citation | |||

| | last1 = al-Hassan | |||

| | first1 = Ahmad Y. | |||

| | author1-link = Ahmad Y. al-Hassan | |||

| | last2 = Hill | |||

| | first2 = Donald R. | |||

| | author2-link = Donald Routledge Hill | |||

| | title = Islamic Technology. An Illustrated History | |||

| | year = 1992 | |||

| | publisher = Cambridge University Press | |||

| | isbn = 0-521-42239-6 | |||

| | url-access = registration | |||

| | url = https://archive.org/details/islamictechnolog0000hasa | |||

| }} | |||

| *{{Citation | |||

| | last = Laur-Belart | |||

| | first = Rudolf | |||

| | title = Führer durch Augusta Raurica | |||

| | place = Augst | |||

| | year = 1988 | |||

| | edition = 5th | |||

| }} | |||

| * {{Citation | |||

| |last=Lucas | |||

| |first=Adam Robert | |||

| |title=Industrial Milling in the Ancient and Medieval Worlds. A Survey of the Evidence for an Industrial Revolution in Medieval Europe | |||

| |journal=Technology and Culture | |||

| |volume=46 | |||

| |issue=1 | |||

| |pages=1–30 | |||

| |year=2005 | |||

| |doi=10.1353/tech.2005.0026 | |||

| |s2cid=109564224 | |||

| }} | |||

| *{{Citation | |||

| | last = Mangartz | |||

| | first = Fritz | |||

| | journal = Archäologisches Korrespondenzblatt | |||

| | title = Zur Rekonstruktion der wassergetriebenen byzantinischen Steinsägemaschine von Ephesos, Türkei. Vorbericht | |||

| | pages = 573–590 | |||

| | issue = 1 | |||

| | volume = 36 | |||

| | year = 2006 | |||

| }} | |||

| *{{Citation | |||

| | last = Mangartz | |||

| | first = Fritz | |||

| | title = Die byzantinische Steinsäge von Ephesos. Baubefund, Rekonstruktion, Architekturteile | |||

| | series = Monographs of the RGZM | |||

| | volume = 86 | |||

| | publisher = Römisch-Germanisches Zentralmuseum | |||

| | location = Mainz | |||

| | year = 2010 | |||

| | isbn = 978-3-88467-149-8 | |||

| }} | |||

| *{{Citation | last = Needham | first = Joseph | title = Science and Civilisation in China: Volume 4, Physics and Physical Technology: Part 2, Mechanical Engineering | publisher = Cambridge University Press | year = 1986 | isbn = 0-521-05803-1}} | |||

| *{{citation|title=Light and Heavy Vehicle Technology|first=Malcolm J.|last=Nunney|year=2007|edition=4th|isbn=978-0-7506-8037-0|publisher=Elsevier Butterworth-Heinemann}} | |||

| *{{Citation | |||

| | last1 = Ritti | |||

| | first1 = Tullia | |||

| | last2 = Grewe | |||

| | first2 = Klaus | |||

| | last3 = Kessener | |||

| | first3 = Paul | |||

| | title = A Relief of a Water-powered Stone Saw Mill on a Sarcophagus at Hierapolis and its Implications | |||

| | journal = Journal of Roman Archaeology | |||

| | pages = 138–163 | |||

| | volume = 20 | |||

| | year = 2007 | |||

| | doi = 10.1017/S1047759400005341 | |||

| | s2cid = 161937987 | |||

| }} | |||

| *{{Citation | |||

| | last = Schiöler | |||

| | first = Thorkild | |||

| | year = 2009 | |||

| | title = Die Kurbelwelle von Augst und die römische Steinsägemühle | |||

| | periodical = Helvetia Archaeologica | |||

| | volume = 40 | |||

| | issue = 159/160 | |||

| | pages = 113–124 | |||

| }} | |||

| *{{Citation | |||

| | last = Volpert | |||

| | first = Hans-Peter | |||

| | journal = Bericht der Bayerischen Bodendenkmalpflege | |||

| | title = Eine römische Kurbelmühle aus Aschheim, Lkr. München | |||

| | pages = 193–199 | |||

| | volume = 38 | |||

| | year = 1997 | |||

| | isbn = 3-7749-2903-3 | |||

| }} | |||

| *{{Citation | |||

| | last = White | |||

| | first = Lynn Jr. | |||

| | author-link = Lynn Townsend White Jr. | |||

| | title = Medieval Technology and Social Change | |||

| | place = Oxford | |||

| | year = 1962 | |||

| | publisher = At the Clarendon Press | |||

| }} | |||

| *{{Citation | |||

| | last = Wilson | |||

| | first = Andrew | |||

| | author-link = Andrew Wilson (classical archaeologist) | |||

| | year = 2002 | |||

| | title = Machines, Power and the Ancient Economy | |||

| | periodical = ] | |||

| | volume = 92 | |||

| | pages = 1–32 | |||

| }} | |||

| ==External links== | |||

| *Interactive crank animation https://www.desmos.com/calculator/8l2kvyivqo | |||

| *D & T Mechanisms – Interactive Tools for Teachers (applets) https://web.archive.org/web/20140714155346/http://www.content.networcs.net/tft/mechanisms.htm | |||

| *{{Cite book | |||

| | last = Grewe | |||

| | first = Klaus | |||

| | editor-last = Bachmann | |||

| | editor-first = Martin | |||

| | contribution = Die Reliefdarstellung einer antiken Steinsägemaschine aus Hierapolis in Phrygien und ihre Bedeutung für die Technikgeschichte. Internationale Konferenz 13.−16. Juni 2007 in Istanbul | |||

| | title = Bautechnik im antiken und vorantiken Kleinasien | |||

| | url = http://www.freundeskreis-roemerkanal.de/Text/BAUTECHNIK%20IM%20ANTIKEN%20UND.pdf | |||

| | series = Byzas | |||

| | volume = 9 | |||

| | publisher = Ege Yayınları/Zero Prod. Ltd. | |||

| | location = Istanbul | |||

| | year = 2009 | |||

| | isbn = 978-975-807-223-1 | |||

| | pages = 429–454 | |||

| | language = de | |||

| | url-status = dead | |||

| | archive-url = https://web.archive.org/web/20110511200049/http://www.freundeskreis-roemerkanal.de/Text/BAUTECHNIK%20IM%20ANTIKEN%20UND.pdf | |||

| | archive-date = 2011-05-11 | |||

| }} | |||

| {{Automotive engine}} | {{Automotive engine|state=collapsed}} | ||

| {{Steam engine configurations|state=collapsed}} | |||

| {{Authority control}} | |||

| ] | ] | ||

| Line 130: | Line 312: | ||

| ] | ] | ||

| ] | ] | ||

| ] | |||

Latest revision as of 21:46, 26 November 2024

Mechanism for converting reciprocating motion to rotation For other uses, see Crankshaft (disambiguation).

A crankshaft is a mechanical component used in a piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating shaft containing one or more crankpins, that are driven by the pistons via the connecting rods.

The crankpins are also called rod bearing journals, and they rotate within the "big end" of the connecting rods.

Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting or machining process.

Design

The crankshaft is located within the engine block and held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration.

A crankshaft is subjected to enormous stresses, in some cases more than 8.6 tonnes (19,000 pounds) per cylinder. Crankshafts for single-cylinder engines are usually a simpler design than for engines with multiple cylinders.

Bearings

Main article: Main bearingThe crankshaft is able to rotate in the engine block due to the 'main bearings'. Since the crankshaft is subject to large horizontal and torsional forces from each cylinder, these main bearings are located at various points along the crankshaft, rather than just one at each end. The number of main bearings is determined based on the overall load factor and the maximum engine speed. Crankshafts in diesel engines often use a main bearing between every cylinder and at both ends of the crankshaft, due to the high forces of combustion present.

Flexing of the crankshaft was a factor in V8 engines replacing straight-eight engines in the 1950s; the long crankshafts of the latter suffered from an unacceptable amount of flex when engine designers began using higher compression ratios and higher engine speeds (RPM).

Piston stroke

The distance between the axis of the crankpins and the axis of the crankshaft determines the stroke length of the engine.

Most modern car engines are classified as "over square" or short-stroke, wherein the stroke is less than the diameter of the cylinder bore. A common way to increase the low-RPM torque of an engine is to increase the stroke, sometimes known as "stroking" the engine. Historically, the trade-off for a long-stroke engine was a lower rev limit and increased vibration at high RPM, due to the increased piston velocity.

Cross-plane and flat-plane configurations

When designing an engine, the crankshaft configuration is closely related to the engine's firing order.

Most production V8 engines (such as the Ford Modular engine and the General Motors LS engine) use a cross-plane crank whereby the crank throws are spaced 90 degrees apart. However, some high-performance V8 engines (such as the Ferrari 488) instead use a flat-plane crank, whereby the throws are spaced 180° apart, which essentially results in two inline-four engines sharing a common crankcase. Flat-plane engines are usually able to operate at higher RPM, however they have higher second-order vibrations, so they are better suited to racing car engines.

Engine balance

For some engines it is necessary to provide counterweights for the reciprocating mass of the piston, conrods and crankshaft, in order to improve the engine balance. These counterweights are typically cast as part of the crankshaft but, occasionally, are bolt-on pieces.

Flying arms

In some engines, the crankshaft contains direct links between adjacent crankpins, without the usual intermediate main bearing. These links are called flying arms. This arrangement is sometimes used in V6 and V8 engines, in order to maintain an even firing interval while using different V angles, and to reduce the number of main bearings required. The downside of flying arms is that the rigidity of the crankshaft is reduced, which can cause problems at high RPM or high power outputs.

Counter-rotating crankshafts

In most engines, each connecting rod is attached a single crankshaft, which results in the angle of the connecting rod varying as the piston moves through its stroke. This variation in angle pushes the pistons against the cylinder wall, which causes friction between the piston and cylinder wall. To prevent this, some early engines – such as the 1900–1904 Lanchester Engine Company flat-twin engines – connected each piston to two crankshafts that are rotating in opposite directions. This arrangement cancels out the lateral forces and reduces the requirement for counterweights. This design is rarely used, however a similar principle applies to balance shafts, which are occasionally used.

Construction

| This section does not cite any sources. Please help improve this section by adding citations to reliable sources. Unsourced material may be challenged and removed. (September 2022) (Learn how and when to remove this message) |

Forged crankshafts

Crankshafts can be created from a steel bar using roll forging. Today, manufacturers tend to favour the use of forged crankshafts due to their lighter weight, more compact dimensions and better inherent damping. With forged crankshafts, vanadium micro-alloyed steels are mainly used as these steels can be air-cooled after reaching high strengths without additional heat treatment, except for the surface hardening of the bearing surfaces. The low alloy content also makes the material cheaper than high-alloy steels. Carbon steels also require additional heat treatment to reach the desired properties.

Cast crankshafts

Another construction method is to cast the crankshaft from ductile iron. Cast iron crankshafts are today mostly found in cheaper production engines where the loads are lower.

Machined crankshafts

Crankshafts can also be machined from billet, often a bar of high quality vacuum remelted steel. Though the fiber flow (local inhomogeneities of the material's chemical composition generated during casting) does not follow the shape of the crankshaft (which is undesirable), this is usually not a problem since higher quality steels, which normally are difficult to forge, can be used. Per unit, these crankshafts tend to be expensive due to the large amount of material that must be removed with lathes and milling machines, the high material cost, and the additional heat treatment required. However, since no expensive tooling is needed, this production method allows small production runs without high up-front costs.

History

Crank

Main article: Crank (mechanism) § HistoryAsia

The earliest hand-operated cranks appeared in China during the Han dynasty (202 BC – 220 AD). They were used for silk-reeling, hemp-spinning, for the agricultural winnowing fan, in the water-powered flour-sifter, for hydraulic-powered metallurgic bellows, and in the well windlass. Pottery models with crank operated winnowing fans were unearthed dating back to the Western Han dynasty (202 BC - 9 AD). The rotary winnowing fan greatly increased the efficiency of separating grain from husks and stalks. The Chinese used the crank-and-connecting rod in ancient blasting apparatus, textile machinery and agricultural machinery no later than the Western Han dynasty (202 BC – 9 AD). Eventually crank-and-connecting rods were used in the inter-conversion or rotary and reciprocating motion for other applications such as flour-sifting, treadle spinning wheels, water-powered furnace bellows, and silk-reeling machines.

Middle East

Ancient Egyptians had manual drills resembling a crank at the time of the Old Kingdom (2686–2181 BCE) and even a hieroglyph for the tool. However the Ancient Egyptian drill did not operate as a true crank.

Later evidence for the crank, combined with a connecting rod in a machine, appears in the Ancient Greek Hierapolis sawmill in Roman Asia from the 3rd century AD and two stone sawmills at Gerasa, Roman Syria, and Ephesus, Greek Ionia under Rome, (both 6th century AD). On the pediment of the Hierapolis mill, a waterwheel fed by a mill race is shown powering via a gear train two frame saws which cut rectangular blocks by the way of some kind of connecting rods and, through mechanical necessity, cranks. The accompanying inscription is in Greek. The crank and connecting rod mechanisms of the other two archaeologically attested sawmills worked without a gear train.

The crank appears in the mid-9th century in several of the hydraulic devices described by the Banū Mūsā brothers in their Book of Ingenious Devices. These devices, however, made only partial rotations and could not transmit much power, although only a small modification would have been required to convert it to a crankshaft.

Al-Jazari (1136–1206) described a crank and connecting rod system in a rotating machine in two of his water-raising machines. His twin-cylinder pump incorporated a crankshaft. A crank is later also described in an early 15th century Arabic manuscript of Hero of Alexandria's Mechanics.

Europe and Roman Empire

See also: List of Roman watermills, Medieval technology, and Renaissance technology

The first rotary hand mills, or rotary querns, appeared in Spain (600 BC – 500 BC), before they spread to the East. The handle near the outer edge of the rotary part being the crank and human arm powering the rotation would be the connecting rod. However according to F. Lisheng and T. Qingjun, the hand-crank of the rotary quern was different from a crank, which was the combination of a hand-crank and a push-and-pull connecting rod by a hinge.

The Antikythera mechanism, dated to around 200 BC, used a crank as a part of its mechanism. The crank was used to manually introduce dates.

Evidence for the crank combined with a connecting rod, appears in the Ancient Greek Hierapolis mill, dating to the 3rd century AD under the Roman Empire; they are also found in stone sawmills in Roman Syria and Ephesus, Greek Ionia under Rome, dating to the 6th century. The pediment of the Hierapolis mill shows a waterwheel fed by a mill race powering via a gear train two frame saws which cut blocks by the way of some kind of connecting rods and cranks. The crank and connecting rod mechanisms of the other two archaeologically attested sawmills worked without a gear train.

A Roman iron crank dating to the 2nd century AD was excavated in Augusta Raurica, Switzerland. The crank-operated Roman mill is dated to the late 2nd century.

Water-powered marble saws in Germany were mentioned by the late 4th century poet Ausonius; about the same time, these mill types seem also to be indicated by Greek Saint Gregory of Nyssa from Anatolia.

A rotary grindstone operated by a crank handle is shown in the Carolingian manuscript Utrecht Psalter; the pen drawing of around 830 goes back to a late antique original. Cranks used to turn wheels are also depicted or described in various works dating from the tenth to thirteenth centuries.

The first depictions of the compound crank in the carpenter's brace appear between 1420 and 1430 in northern European artwork. The rapid adoption of the compound crank can be traced in the works of an unknown German engineer writing on the state of military technology during the Hussite Wars: first, the connecting-rod, applied to cranks, reappeared; second, double-compound cranks also began to be equipped with connecting-rods; and third, the flywheel was employed for these cranks to get them over the 'dead-spot'. The concept was much improved by the Italian engineer and writer Roberto Valturio in 1463, who devised a boat with five sets, where the parallel cranks are all joined to a single power source by one connecting-rod, an idea also taken up by his compatriot Italian painter Francesco di Giorgio.

The crank had become common in Europe by the early 15th century, as seen in the works of the military engineer Konrad Kyeser (1366–after 1405). Devices depicted in Kyeser's Bellifortis include cranked windlasses for spanning siege crossbows, cranked chain of buckets for water-lifting and cranks fitted to a wheel of bells. Kyeser also equipped the Archimedes' screws for water-raising with a crank handle, an innovation which subsequently replaced the ancient practice of working the pipe by treading.

Pisanello painted a piston-pump driven by a water-wheel and operated by two simple cranks and two connecting-rods. The 15th century also saw the introduction of cranked rack-and-pinion devices, called cranequins, which were fitted to the crossbow's stock as a means of exerting even more force while spanning the missile weapon. In the textile industry, cranked reels for winding skeins of yarn were introduced.

The Luttrell Psalter, dating to around 1340, describes a grindstone which was rotated by two cranks, one at each end of its axle; the geared hand-mill, operated either with one or two cranks, appeared later in the 15th century. Around 1480, the early medieval rotary grindstone was improved with a treadle and crank mechanism. Cranks mounted on push-carts first appear in a German engraving of 1589.

Crankshaft

In 9th century Abbasid Baghdad, automatically operated cranks appear in several of the hydraulic devices described by the Banū Mūsā brothers in the Book of Ingenious Devices. These automatically operated cranks appear in several devices, two of which contain an action which approximates to that of a crankshaft, five centuries before the earliest known European description of a crankshaft. However, the automatic crank mechanism described by the Banū Mūsā would not have allowed a full rotation, but only a small modification was required to convert it to a crankshaft.

In the Artuqid Sultanate, Arab engineer Ismail al-Jazari (1136–1206) described a crank and connecting rod system in a rotating machine for two of his water-raising machines, which include both crank and shaft mechanisms.

The Italian physician Guido da Vigevano (c. 1280 – c. 1349), planning for a new Crusade, made illustrations for a paddle boat and war carriages that were propelled by manually turned compound cranks and gear wheels, identified as an early crankshaft prototype by Lynn Townsend White.

Crankshafts were described by Leonardo da Vinci (1452–1519) and a Dutch farmer and windmill owner by the name Cornelis Corneliszoon van Uitgeest in 1592. His wind-powered sawmill used a crankshaft to convert a windmill's circular motion into a back-and-forward motion powering the saw. Corneliszoon was granted a patent for his crankshaft in 1597.

From the 16th century onwards, evidence of cranks and connecting rods integrated into machine design becomes abundant in the technological treatises of the period: Agostino Ramelli's The Diverse and Artifactitious Machines of 1588 depicts eighteen examples, a number that rises in the Theatrum Machinarum Novum by Georg Andreas Böckler to 45 different machines. Cranks were formerly common on some machines in the early 20th century; for example almost all phonographs before the 1930s were powered by clockwork motors wound with cranks. Reciprocating piston engines use cranks to convert the linear piston motion into rotational motion. Internal combustion engines of early 20th century automobiles were usually started with hand cranks, before electric starters came into general use.

See also

- Bicycle crankset

- Brace (tool)

- Cam (mechanism)

- Cam engine

- Camshaft

- Crank (mechanism)

- Crankcase

- Crankshaft torsional vibration

- List of auto parts

- Piston motion equations

- Tunnel crankshaft

- Scotch yoke

- Swashplate

References

- ^ "How the crankshaft works – All the details". How a Car Works. Retrieved 27 August 2022.

- "Definition of CRANKSHAFT". Merriam-Webster Dictionary. 17 October 2024.

- "Crankshaft: Parts, Function, Types, Diagram & More". The Engineers Post. 27 May 2021. Retrieved 1 September 2022.

- McCune, R. C.; Weber, G. A. (1 January 2001). "Automotive Engine materials". Encyclopedia of Materials: Science and Technology. Elsevier. pp. 426–434. Bibcode:2001emst.book..426M. doi:10.1016/B0-08-043152-6/00086-3. ISBN 9780080431529. Retrieved 1 September 2022.

- "How Does A Flywheel Work? Explained In Simple Words". Car From Japan. 13 June 2018. Retrieved 1 September 2022.

- "How to Build Racing Engines: Crankshafts Guide". www.musclecardiy.com. 5 April 2015. Retrieved 27 October 2019.

- "Flat-Plane Cranks, Part 2 — Calculating Crankshaft Secondary Forces". EngineLabs. 20 January 2022. Retrieved 28 August 2022.

- Bosch, Robert (2004). Automotive Handbook. Robert Bosch. p. 465. ISBN 978-0-8376-1243-0. Retrieved 28 August 2022.

- "A Brief History Of The Straight-Eight Engine – Carole Nash". Carole Nash UK. Retrieved 28 August 2022.

- "All you need to know about stroker engines and kits". TorqueCars. 22 December 2020. Retrieved 28 August 2022.

- "What's the best firing order?". EngineLabs. 25 April 2017. Retrieved 30 August 2022.

- "Crankshaft Design Evolution". enginehistory.org. Retrieved 30 August 2022.

- "Flat Plane Crankshafts vs. Crossplane Crankshafts". OnAllCylinders. 15 January 2015. Retrieved 30 August 2022.

- "Ferrari 488 Spider debuts in Frankfurt, is faster than Lamborghini's new drop-top in every way". Autoweek. 15 September 2015. Retrieved 30 August 2022.

- "2016 Ferrari 488 Spider: Losing the Roof Doesn't Compromise the Magic". Road & Track. 15 October 2015. Retrieved 30 August 2022.

- "Difference Between Cross-Plane and Flat-Plane Cranks". MotorTrend. 15 June 2022. Retrieved 30 August 2022.

- "How The Flat-Plane Crank Turns Muscle Cars Into Exotics". CarBuzz. 8 April 2016. Retrieved 30 August 2022.

- "Crankshaft Balance Factors". Ohio Crankshaft. Retrieved 31 August 2022.

- "Finding Balance (Part 1): The Basics of Crankshaft Balancing". OnAllCylinders. 17 March 2016. Retrieved 31 August 2022.

- Nunney, Malcolm J. (2007). Light and Heavy Vehicle Technology (4th ed.). Elsevier Butterworth-Heinemann. ISBN 978-0-7506-8037-0.

- "Crankshaft guide – Flat vs Cross plane & lightened crankshafts". TorqueCars. 30 June 2015. Retrieved 31 August 2022.

- Andersson BS (1991), Company's perspective in vehicle tribology. In: 18th Leeds-Lyon Symposium (eds D Dowson, CM Taylor and MGodet), Lyon, France, 3–6 September 1991, New York: Elsevier, pp. 503–506

- "Cast vs Forged Crankshaft". www.dropforging.net. Retrieved 2024-07-31.

- Ritti, Grewe & Kessener 2007, p. 159

- ^ Lucas 2005, p. 5, fn. 9

- ^ Needham 1986, pp. 118–119

- Lisheng, Feng; Qingjun, Tong (2009). "Crank-Connecting Rod Mechanism: Its Application in Ancient China and Its Origins". In Hong-Sen Yan; Marco Ceccarelli (eds.). International Symposium on History of Machines and Mechanisms. Springer Science and Business Media. p. 247. ISBN 978-1-4020-9484-2.

- Bautista Paz, Emilio; Ceccarelli, Marco; Otero, Javier Echávarri; Sanz, José Luis Muñoz (2010). A Brief Illustrated History of Machines and Mechanisms. Springer (published May 12, 2010). p. 19. ISBN 978-9048125111.

- Du Bois, George (2014). Understanding China: Dangerous Resentments. Trafford on Demand. ISBN 978-1490745077.

- Lisheng & Qingjun 2009, pp. 236–249

- Needham, Joseph (2007). Mechanical engineering. Science and civilisation in China / by Joseph Needham Vol. 4, Physics and physical technology (6. print ed.). Cambridge: Cambridge Univ. Press. p. 114. ISBN 978-0-521-05803-2.

- Hartenberg, Richard S.; Schmidt, John (1969). "The Egyptian Drill and the Origin of the Crank". Technology and Culture. 10 (2): 155–165. doi:10.2307/3101475. ISSN 0040-165X. JSTOR 3101475.

- Ritti, Grewe & Kessener 2007, p. 161:

Because of the findings at Ephesus and Gerasa the invention of the crank and connecting rod system has had to be redated from the 13th to the 6th c; now the Hierapolis relief takes it back another three centuries, which confirms that water-powered stone saw mills were indeed in use when Ausonius wrote his Mosella.

- ^ Ritti, Grewe & Kessener 2007, pp. 139–141

- ^ Ritti, Grewe & Kessener 2007, pp. 149–153

- Mangartz 2006, pp. 579f.

- ^ A. F. L. Beeston, M. J. L. Young, J. D. Latham, Robert Bertram Serjeant (1990), The Cambridge History of Arabic Literature, Cambridge University Press, p. 266, ISBN 0-521-32763-6

{{citation}}: CS1 maint: multiple names: authors list (link) - al-Hassan & Hill 1992, pp. 45, 61

- ^ Banū Mūsā; Hill, Donald Routledge (1979), The Book of Ingenious Devices (Kitáb al-Ḥiyal) by the Banú (sons of) Músà bin Shákir, Springer Publishing, pp. 23–4, ISBN 90-277-0833-9

- ^ Ahmad Y Hassan. The Crank-Connecting Rod System in a Continuously Rotating Machine.

- Sally Ganchy, Sarah Gancher (2009), Islam and Science, Medicine, and Technology, The Rosen Publishing Group, p. 41, ISBN 978-1-4358-5066-8

- White 1962, p. 170

- ^ Ritti, Grewe & Kessener 2007, p. 161: Because of the findings at Ephesus and Gerasa the invention of the crank and connecting rod system has had to be redated from the 13th to the 6th c; now the Hierapolis relief takes it back another three centuries, which confirms that water-powered stone saw mills were indeed in use when Ausonius wrote his Mosella.

- ^ Ritti, Grewe & Kessener 2007, pp. 158, 159

- ^ Alonso i Martínez, Natalia (2015). ""Moliendo en ibero, moliendo en griego": aculturación y resistencia tecnológica en el Mediterráneo occidental durante la Edad del Hierro". Vegueta: Anuario de la Facultad de Geografía e Historia (15): 23–36. ISSN 1133-598X.

- Needham, Joseph (1965-01-02). Science and Civilisation in China, Part 2, Mechanical Engineering. Cambridge University Press. p. 186. ISBN 978-0-521-05803-2.

- Lisheng & Qingjun 2009, pp. 248–249.

- Voulgaris, Aristeidis; Mouratidis, Christophoros; Vossinakis, Andreas (2023-08-27), The Initial Calibration Date of the Antikythera Mechanism after the Saros spiral mechanical Apokatastasis, arXiv:2203.15045

- Carman, Christián C. (2017). "The Final Date of the Antikythera Mechanism". Journal for the History of Astronomy. 48 (3): 312–323. doi:10.1177/0021828617721553. hdl:11336/72114. ISSN 0021-8286.

- Tyaglova-Fayer, Svetlana (2023-11-14), The new reading of the 3D reconstruction of the Antikythera machine (30-day calendar), retrieved 2024-08-25

- Diolatzis, Ioannis S.; Pavlogeorgatos, Gerasimos (2018-03-01). "Deepening to Antikythera mechanism via its interactivity". Digital Applications in Archaeology and Cultural Heritage. 8: 10–26. doi:10.1016/j.daach.2017.11.005. ISSN 2212-0548.

- Mangartz 2010, pp. 579f.

- Schiöler 2009, pp. 113f.

- Laur-Belart 1988, pp. 51–52, 56, fig. 42

- Volpert 1997, pp. 195, 199

- Wilson 2002, p. 16

- Ritti, Grewe & Kessener 2007, p. 156, fn. 74

- ^ White 1962, p. 110

- Hägermann & Schneider 1997, pp. 425f.

- Needham 1986, pp. 112–113.

- White 1962, p. 112

- ^ White 1962, p. 113

- White 1962, p. 114

- Needham 1986, p. 113.

- ^ White 1962, p. 111

- White 1962, pp. 105, 111, 168

- Hall 1979, pp. 74f.

- White 1962, p. 167

- Donald Hill (2012), The Book of Knowledge of Ingenious Mechanical Devices, page 273, Springer Science + Business Media

- Hall 1979, p. 80

- Townsend White, Lynn (1978). Medieval Religion and Technology: Collected Essays. University of California Press. p. 335. ISBN 9780520035669.

- White 1962, p. 172

Sources

- Frankel, Rafael (2003), "The Olynthus Mill, Its Origin, and Diffusion: Typology and Distribution", American Journal of Archaeology, 107 (1): 1–21, doi:10.3764/aja.107.1.1, S2CID 192167193

- Hägermann, Dieter; Schneider, Helmuth (1997), Propyläen Technikgeschichte. Landbau und Handwerk, 750 v. Chr. bis 1000 n. Chr. (2nd ed.), Berlin, ISBN 3-549-05632-X

{{citation}}: CS1 maint: location missing publisher (link) - Hall, Bert S. (1979), The Technological Illustrations of the So-Called "Anonymous of the Hussite Wars". Codex Latinus Monacensis 197, Part 1, Wiesbaden: Dr. Ludwig Reichert Verlag, ISBN 3-920153-93-6

- al-Hassan, Ahmad Y.; Hill, Donald R. (1992), Islamic Technology. An Illustrated History, Cambridge University Press, ISBN 0-521-42239-6

- Laur-Belart, Rudolf (1988), Führer durch Augusta Raurica (5th ed.), Augst

{{citation}}: CS1 maint: location missing publisher (link) - Lucas, Adam Robert (2005), "Industrial Milling in the Ancient and Medieval Worlds. A Survey of the Evidence for an Industrial Revolution in Medieval Europe", Technology and Culture, 46 (1): 1–30, doi:10.1353/tech.2005.0026, S2CID 109564224

- Mangartz, Fritz (2006), "Zur Rekonstruktion der wassergetriebenen byzantinischen Steinsägemaschine von Ephesos, Türkei. Vorbericht", Archäologisches Korrespondenzblatt, 36 (1): 573–590

- Mangartz, Fritz (2010), Die byzantinische Steinsäge von Ephesos. Baubefund, Rekonstruktion, Architekturteile, Monographs of the RGZM, vol. 86, Mainz: Römisch-Germanisches Zentralmuseum, ISBN 978-3-88467-149-8

- Needham, Joseph (1986), Science and Civilisation in China: Volume 4, Physics and Physical Technology: Part 2, Mechanical Engineering, Cambridge University Press, ISBN 0-521-05803-1

- Nunney, Malcolm J. (2007), Light and Heavy Vehicle Technology (4th ed.), Elsevier Butterworth-Heinemann, ISBN 978-0-7506-8037-0

- Ritti, Tullia; Grewe, Klaus; Kessener, Paul (2007), "A Relief of a Water-powered Stone Saw Mill on a Sarcophagus at Hierapolis and its Implications", Journal of Roman Archaeology, 20: 138–163, doi:10.1017/S1047759400005341, S2CID 161937987